Machine for reassembling bearing seat of supporting roller with positioning function, rotational carrying roller, and servo actuated cover board

A technology for bearing housings and back-up rolls, which is applied to fluid pressure actuating devices, mechanical equipment, metal rolling racks, etc., can solve the problems of low equipment positioning accuracy, potential safety hazards, and low automation, and achieve improved oil coating Work efficiency, elimination of potential safety hazards, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

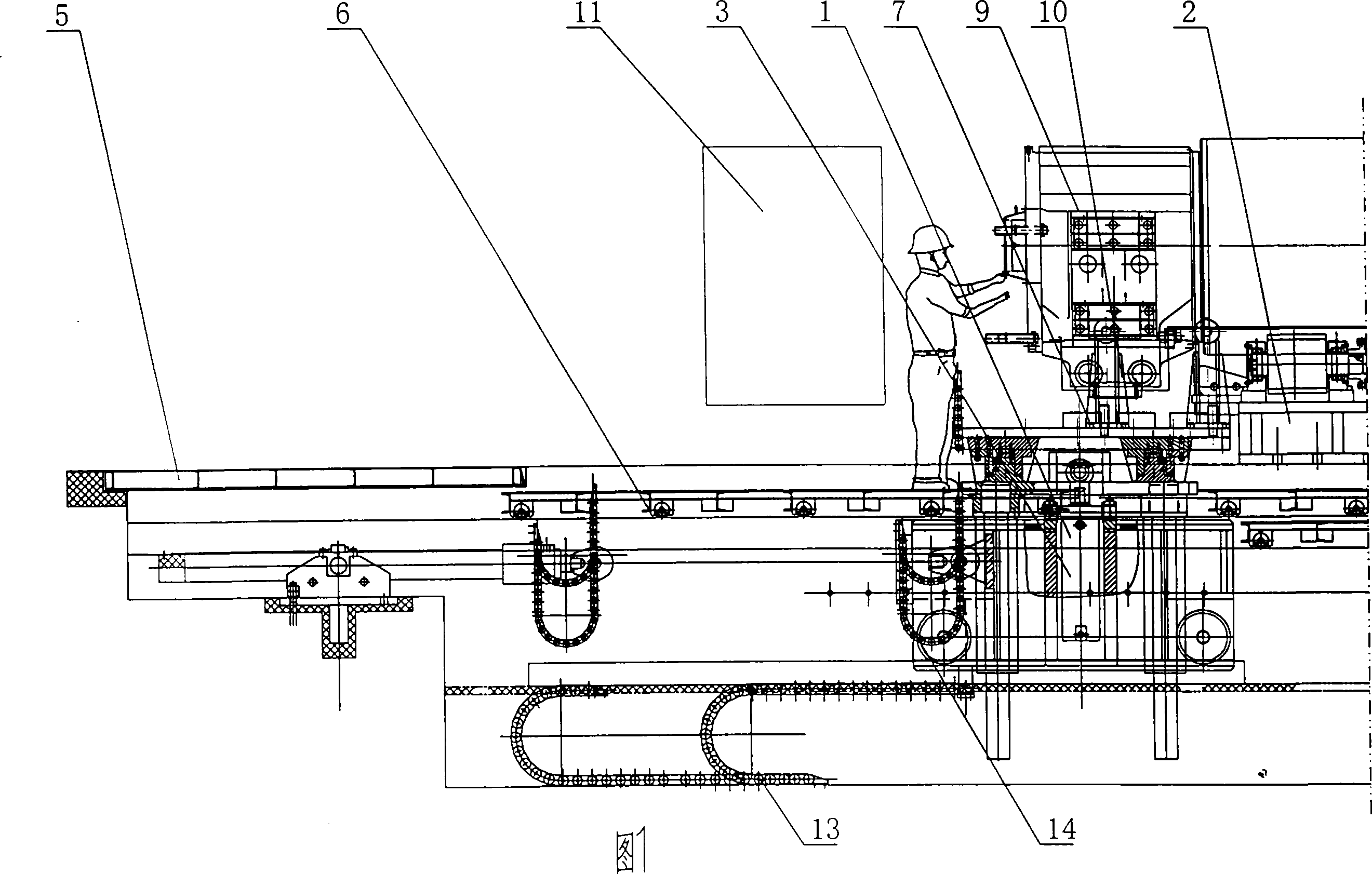

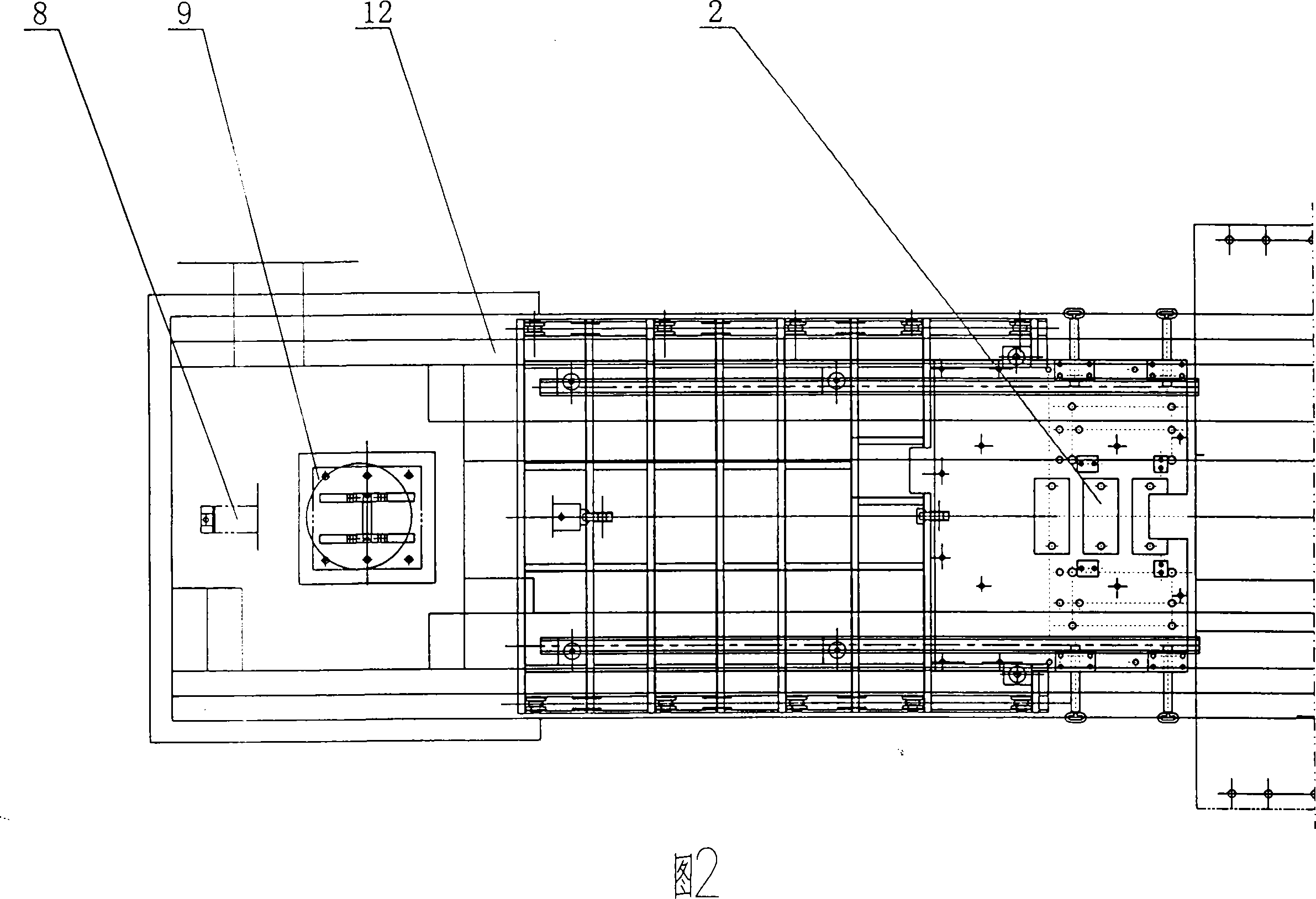

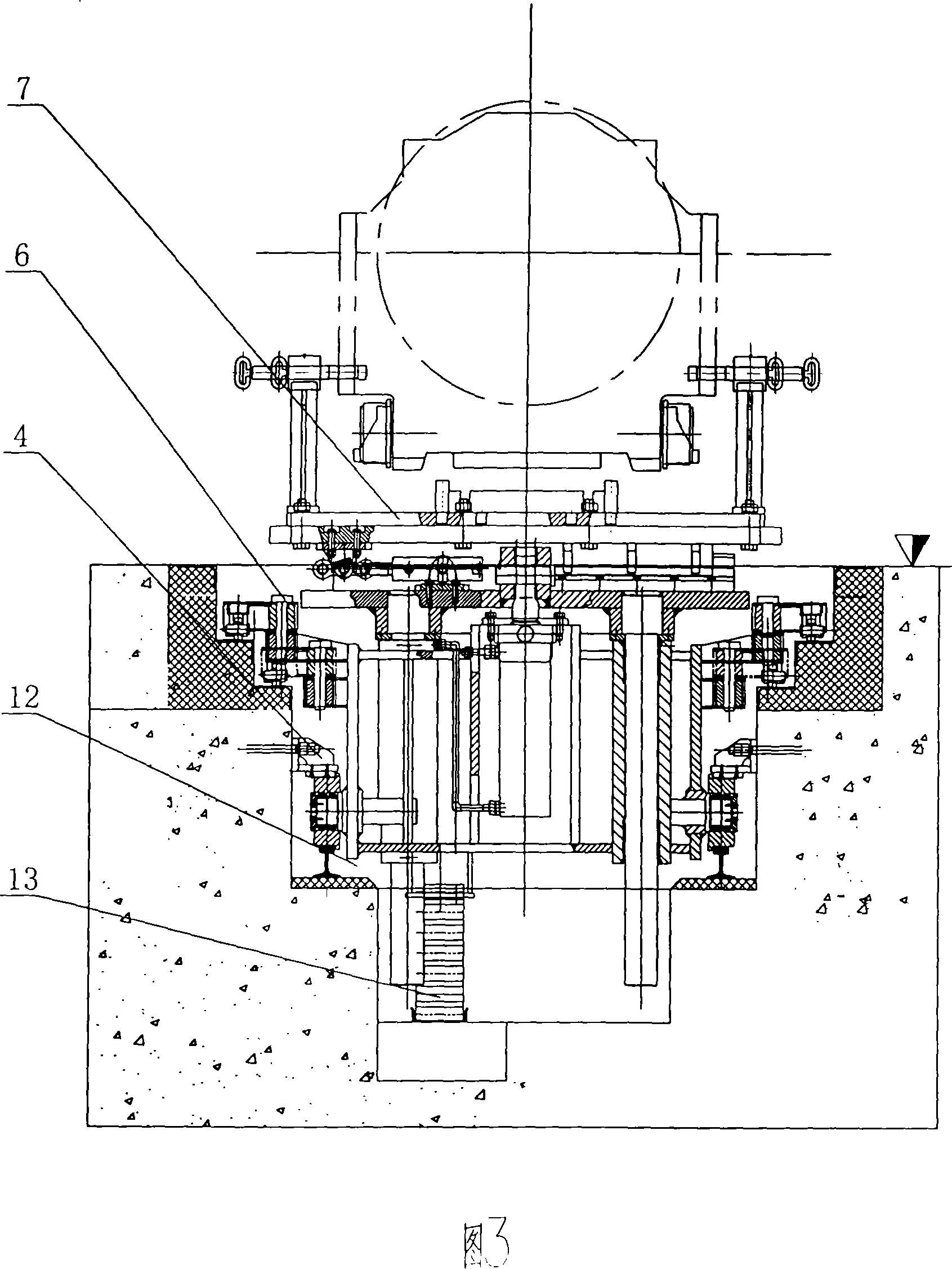

[0030] As shown in Fig. 1, Fig. 2 and Fig. 3, according to the present invention, a support roller chock dismantling machine with positioning, idler roller rotation and follow-up cover plate includes a cart 12 and an anti-tipping device for the cart 4. Cart tow chain driving device, fixed cover plate 5, dismounting frame 7, characterized in that the cart 12 is provided with a horizontal tow chain driving device 13, a vertical tow chain driving device 14, left on the cart , The right side is respectively provided with the left laterally moving supporting plate 6, the right laterally moving supporting plate, and the middle part is equipped with a roll centering device 2, the front and rear ends of the cart are provided with front and rear follow-up covers, and beside the cart is a The electric oiling vehicle 11, the dismounting vehicle 7 are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com