Yarn heating device

A technology for heating devices and filaments, which is applied in the direction of electric heating devices, heat treatment of artificial filaments, electric/magnetic/electromagnetic heating, etc. It can solve the problem of lowering the fixed vibration frequency, not being able to thicken the drive shaft to increase rigidity, and the difficulty of high-speed rotation of the main body of the roller. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

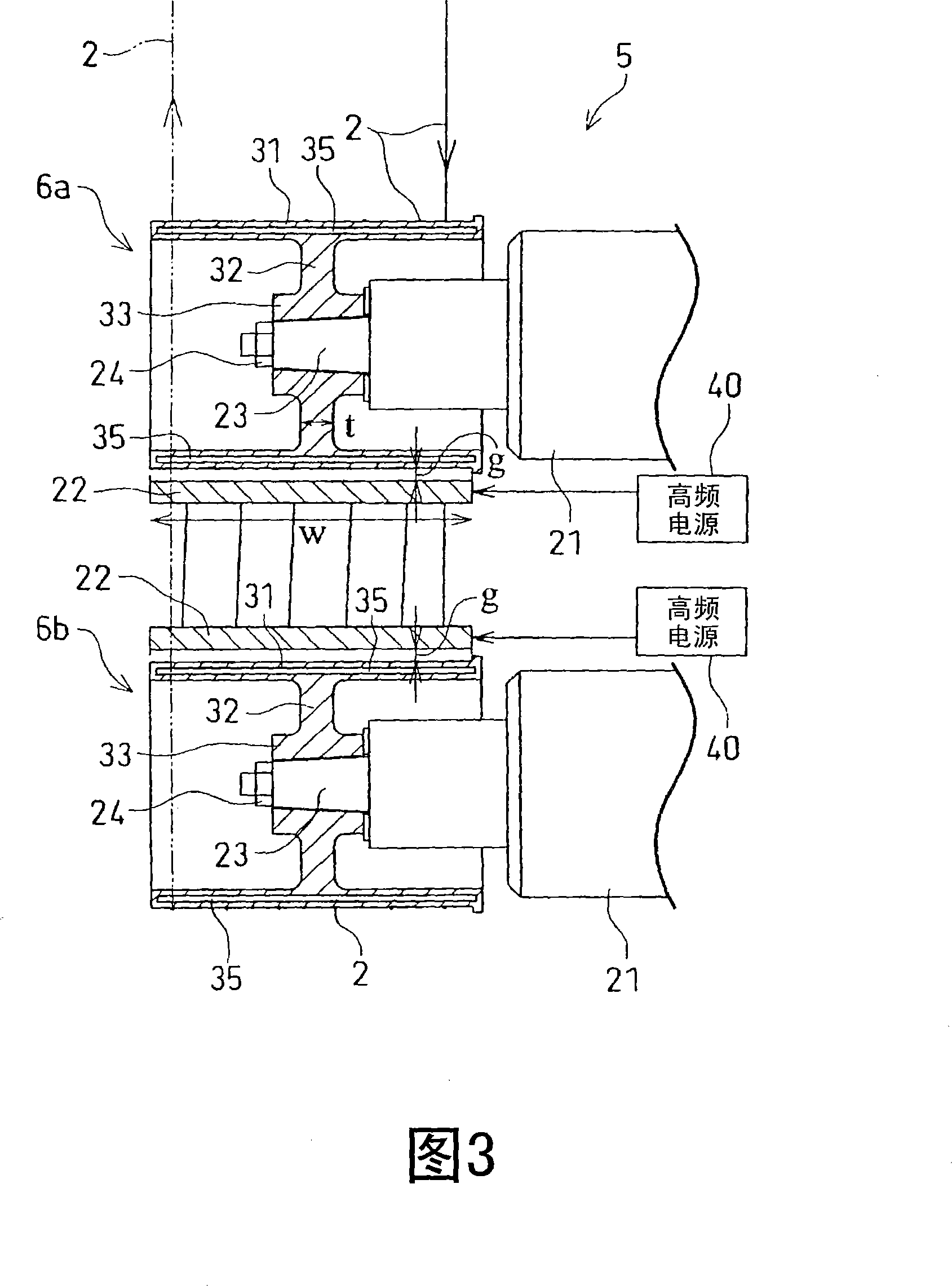

[0023] Embodiments of the invention will be described below with reference to FIGS. 1 to 3 .

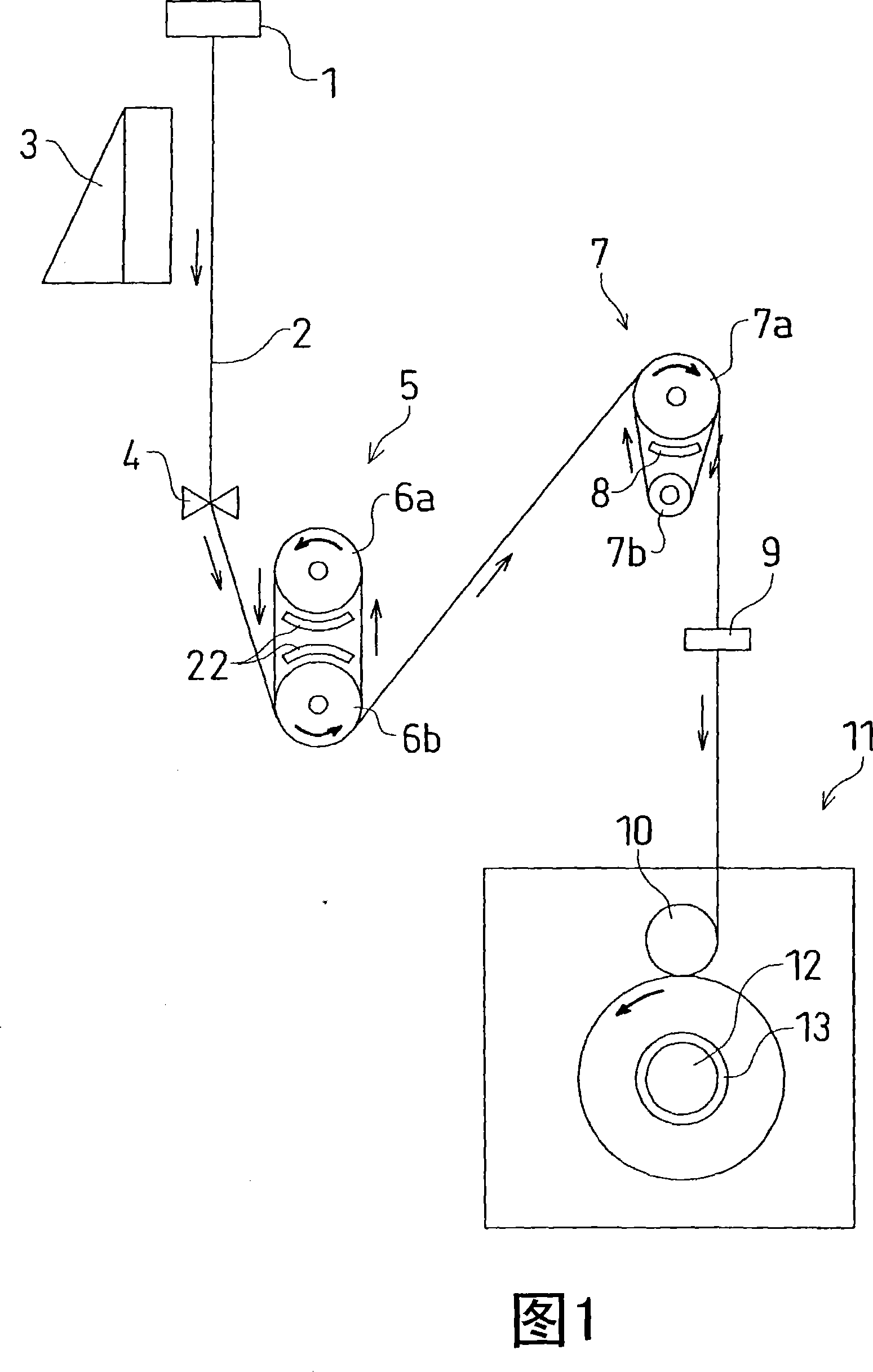

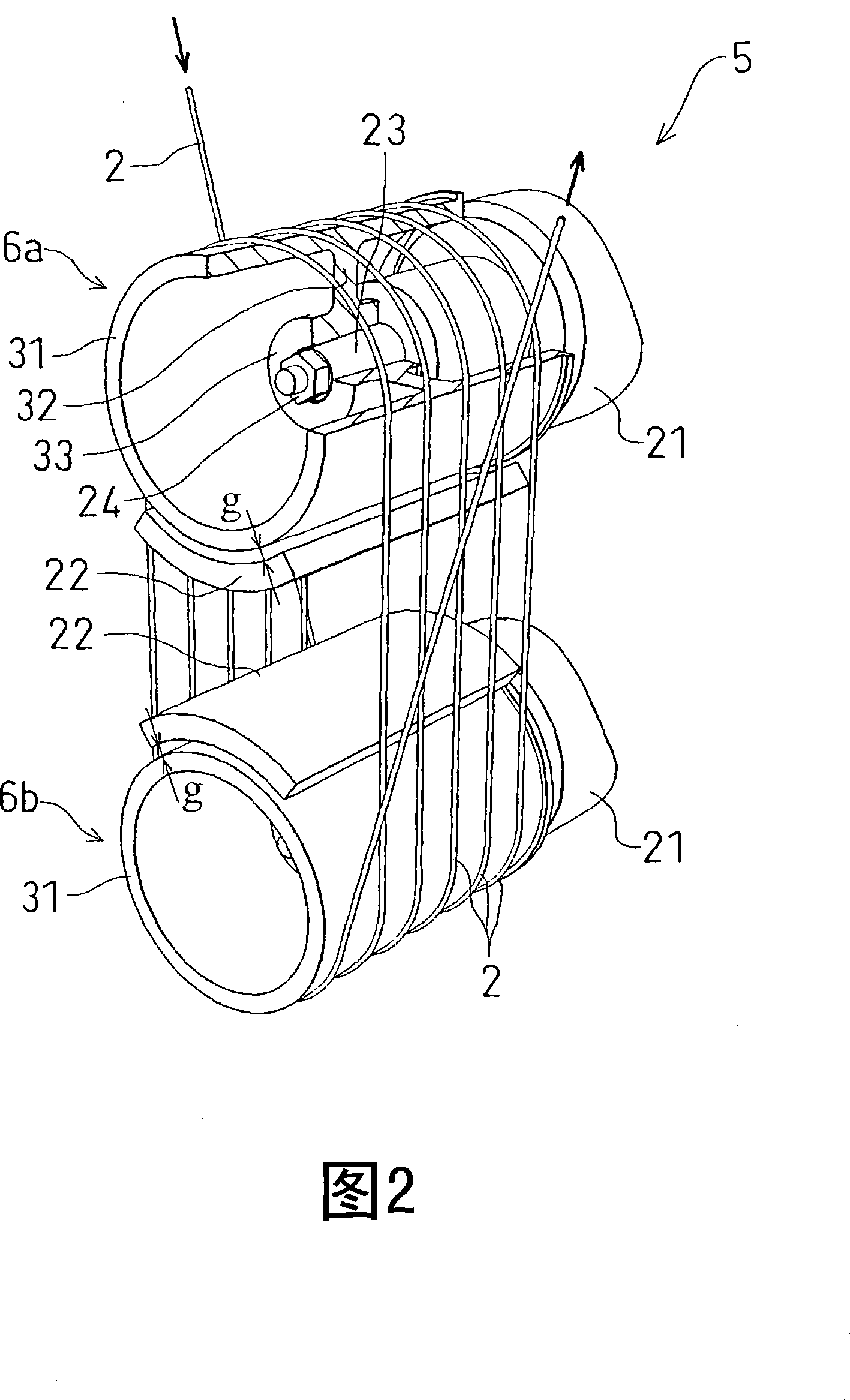

[0024] Fig. 1 shows the overall configuration of a spinning and drawing device (manufacturing device for synthetic fiber yarn) equipped with a yarn heating device 5 according to the present embodiment. In this spinning drawing device, the filament (yarn) 2 in the state of molten polymer ejected from the spinneret 1 is cooled and solidified by the wind blown out from the cooling device 3, and is sent to the yarn heating device 5 through the oiling device 4. . The yarn heating device 5 is configured to include two rollers 6a, 6b arranged one above the other and driven by motors, and the yarn 2 is wound around these rollers 6a, 6b to be heated. The detailed structure of the yarn heating device 5 will be described later.

[0025] On the downstream side of the yarn heating device 5, a drawing roll 7 including a main roll 7a and an auxiliary roll 7b is provided. The main roller 7a is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com