H62 brass polishing liquid and its preparing process

A polishing liquid, brass technology, applied in polishing compositions, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve the problems of high price, difficult to process uniform surface quality, etc. Good quality, the effect of alleviating the effect of mechanical scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

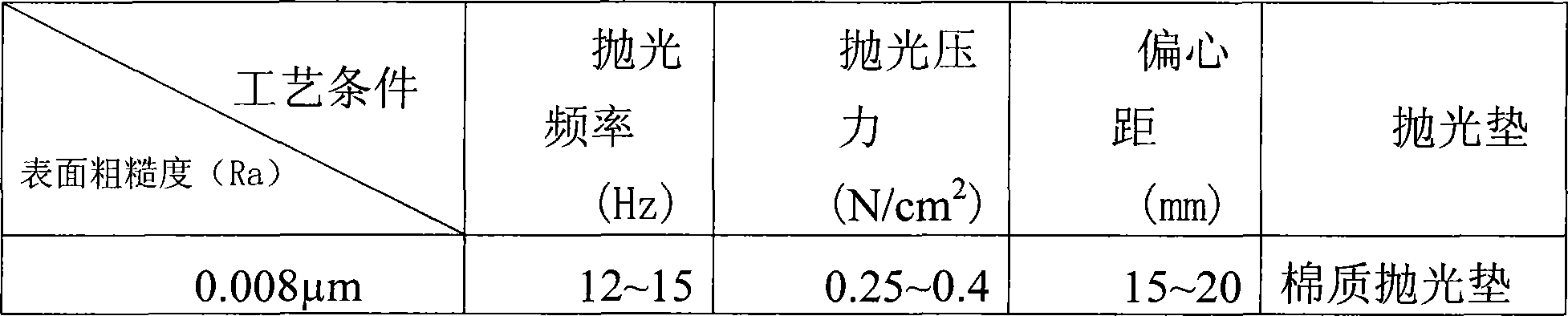

[0019] Example 1: When the ambient temperature is 16°C

[0020] (1) Implementation conditions

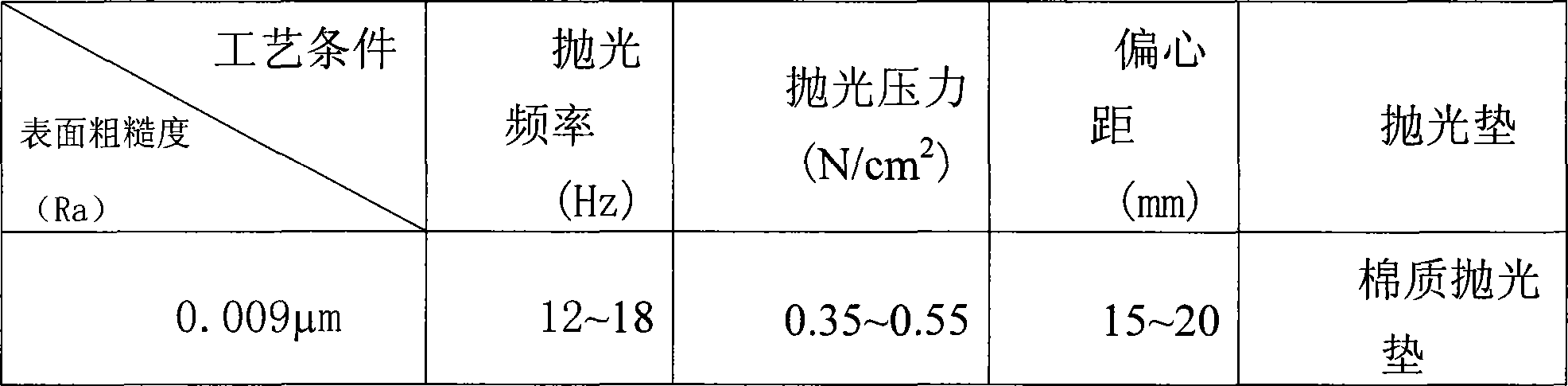

[0021] BDE-1B variable frequency speed adjustable optical two-axis grinding and polishing machine, 2205 surface roughness measuring instrument, special polishing fluid, cotton polishing pad, H62 brass workpiece with a diameter of 80mm and a thickness of 6mm, the polishing parameters are: frequency 12~ 18Hz, polishing pressure 0.35~0.55N / cm 2 , The eccentric distance is 15-20mm, and the polishing time is 30min.

[0022] The manufacturing method of the special polishing liquid is as shown above:

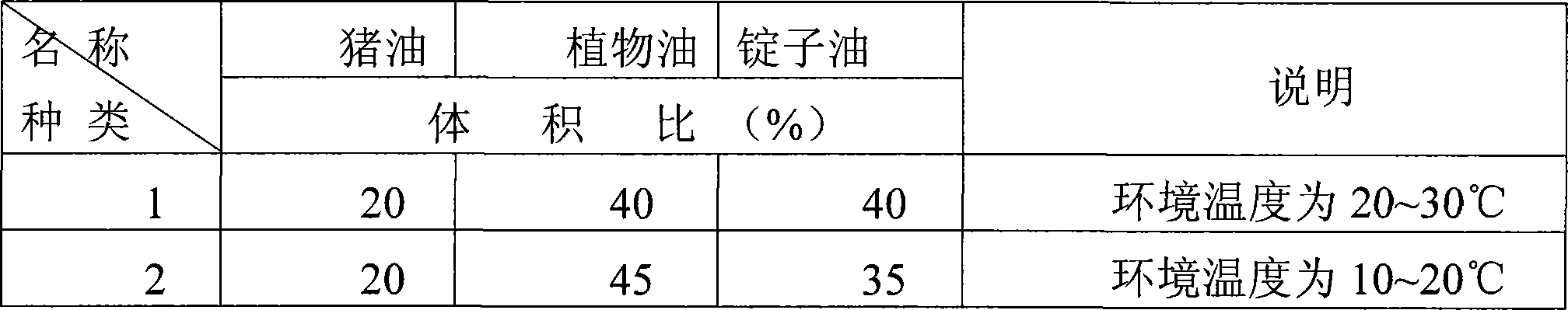

[0023] (2) Proportion of special polishing liquid

[0024] The components in volume ratio are: 2% lard, 2% abrasive, 4.5% vegetable oil, 3.5% spindle oil and 88% kerosene.

[0025] (3) The preparation method is as follows, the following percentages are the volume percentages of the polishing liquid.

[0026] ① Heat 2% lard to melt;

[0027] ②Add Al in the molten lard at a volume ratio of 1:1 2 ...

Embodiment 2

[0031] Example 2: When the ambient temperature is 25°C

[0032] (3) Implementation conditions

[0033] BDE-1B variable frequency speed adjustable optical two-axis grinding and polishing machine, 2205 surface roughness measuring instrument, special polishing fluid, cotton polishing pad, H62 brass workpiece with a diameter of 80mm and a thickness of 6mm, the polishing parameters are: frequency 12~ 18Hz, polishing pressure 0.35~0.55N / cm 2 , The eccentric distance is 15-20mm, and the polishing time is 30min.

[0034] The manufacturing method of the special polishing liquid is as shown above:

[0035] (4) Proportion of special polishing liquid

[0036] The components in volume ratio are: 2% lard, 2% abrasive, 4% vegetable oil, 4% spindle oil and 88% kerosene.

[0037] (3) The preparation method is as follows, the following percentages are the volume percentages of the polishing liquid.

[0038] ① Heat the lard with a volume ratio of 2% to melt;

[0039] ②Add Al in the molten lard at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com