Preparation technology for oats biological fermented milk

A bio-fermentation and preparation process technology, applied in the field of preparation of oat bio-fermented milk, can solve the problems of insufficient conversion of nutrients into absorbable components, single form, etc., so as to inhibit the production of spoilage bacteria and molds, prevent cerebrovascular diseases, reduce The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

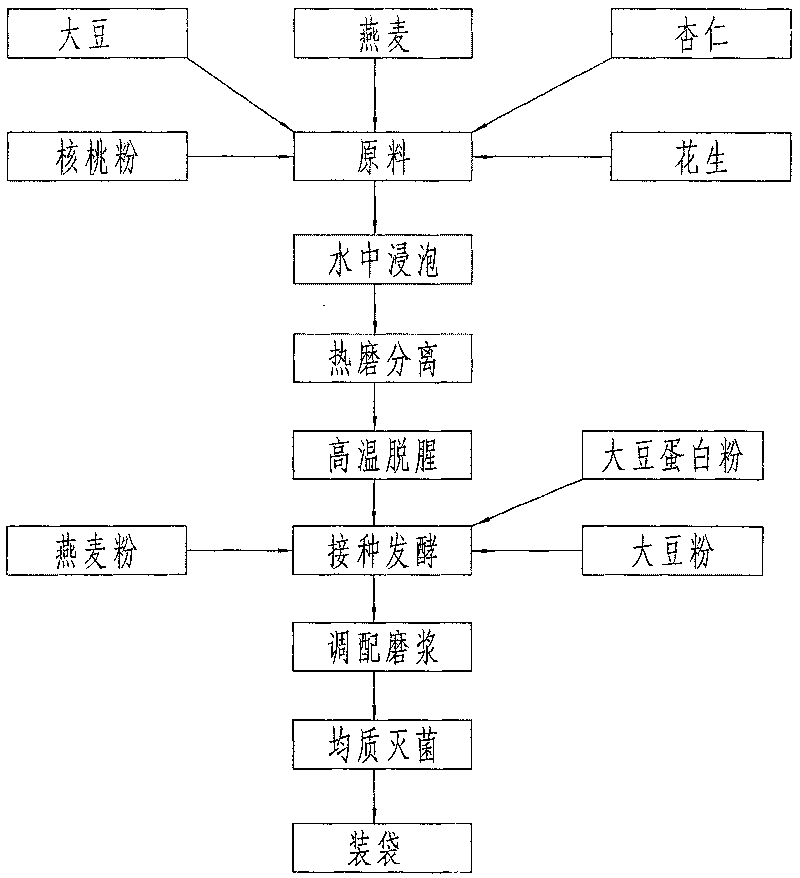

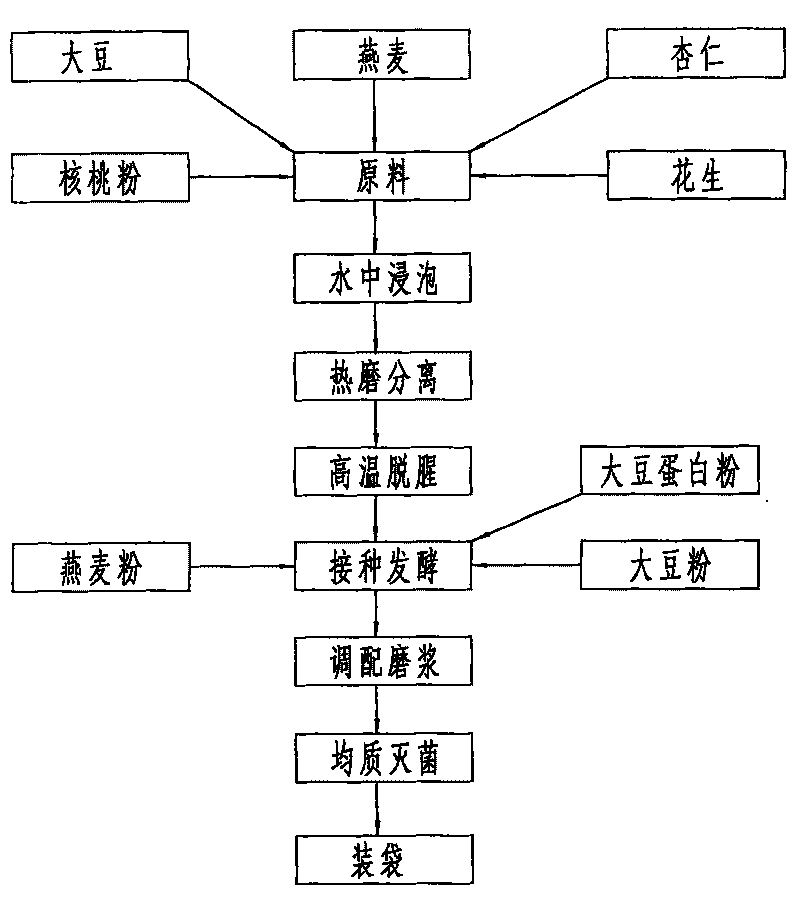

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: raw material is oat and soybean,

[0030] A preparation process of oat biologically fermented milk, comprising the following steps:

[0031] preparation of the fermentation substrate,

[0032] Rinse 5 kg of oats and 2 kg of soybeans that have been cleaned of debris such as stones, moldy particles, etc., with clean water to remove soil, dust, and fine debris.

[0033] 1. Soak oats and soybeans in water respectively, the weight ratio of material to water is 1:3, the water temperature is 20°C, and the time is 8 hours. It is best to add 0.2% NaHCO of the total weight of raw materials 3 , can shorten the soaking time and can remove the pigment in the soybean well.

[0034] The soaked soybeans are blanched with boiling water or steam to inactivate lipoxygenase and reduce the beany smell. The blanching temperature is 95° C. for 7 minutes.

[0035] 2. Mix the oats with the soybeans treated in the previous step for thermal grinding, extraction and separation, us...

Embodiment 2

[0041] Embodiment 2: raw materials are oats and soybeans,

[0042] A preparation process of oat biologically fermented milk, comprising the following steps:

[0043] Preparation of fermentation substrate

[0044] Rinse 5 kg of oats and 3 kg of soybeans that have been cleaned of debris such as stones, moldy particles, etc., with clean water to remove dirt, dust, and fine debris.

[0045] 1. Soak oats and soybeans in water respectively, the weight ratio of material to water is 1:2, the water temperature is 10°C, and the time is 6 hours. It is best to add 0.1% NaHCO 3 , can shorten the soaking time and can remove the pigment in the soybean well.

[0046] The soaked soybeans are blanched with boiling water or steam to inactivate lipoxygenase and reduce the beany smell. The blanching temperature is 90° C. for 2 minutes.

[0047] 2. Mix the oats and the soybeans treated in the previous step for hot grinding, extraction and separation. Use hot water at 80°C, the amount of water is...

Embodiment 3

[0053] Embodiment 3, raw material is oat and soybean,

[0054] A preparation process of oat biologically fermented milk, comprising the following steps:

[0055] Preparation of fermentation substrate

[0056] First, rinse 5 kg of oats and 1 kg of soybeans that have been cleaned of debris such as stones and moldy particles, with clean water to remove soil, dust, and fine debris.

[0057] 1. Soak oats and soybeans in water respectively, the weight ratio of material and water is 1:5, the water temperature is 65°C, and the time is 10 hours. It is best to add 0.3% NaHCO 3 , can shorten the soaking time and can remove the pigment in the soybean well.

[0058] The soaked soybeans are blanched with boiling water or steam to inactivate lipoxygenase and reduce the beany smell. The blanching temperature is 100° C. for 10 minutes.

[0059] 2. Mix the oats and the soybeans treated in the previous step for hot grinding, extraction and separation. Use hot water at 90°C, the amount of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com