Solid material rotary valve

A solid material and rotary valve technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of low power consumption and low cost, and achieve low power consumption, low cost and good air tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

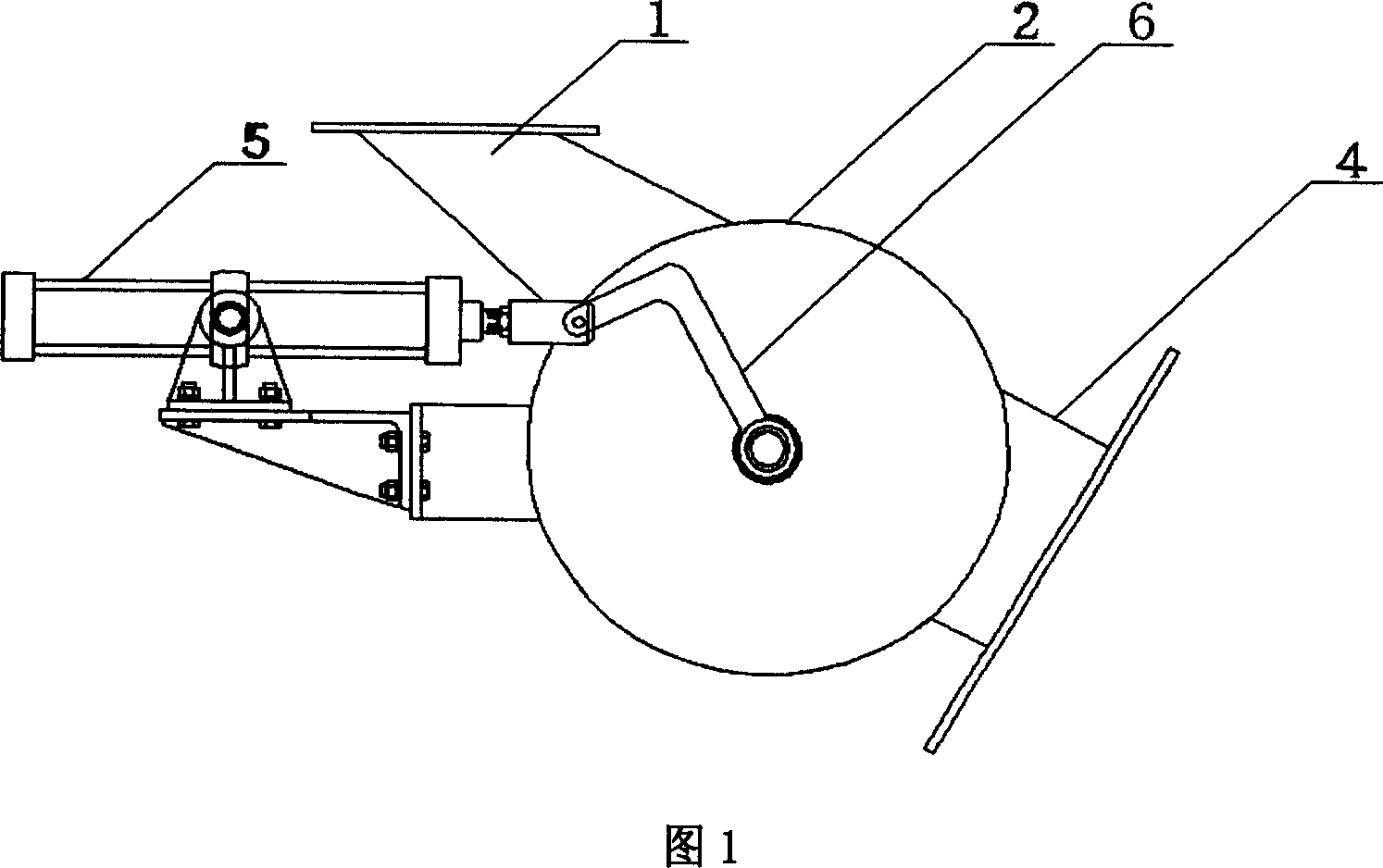

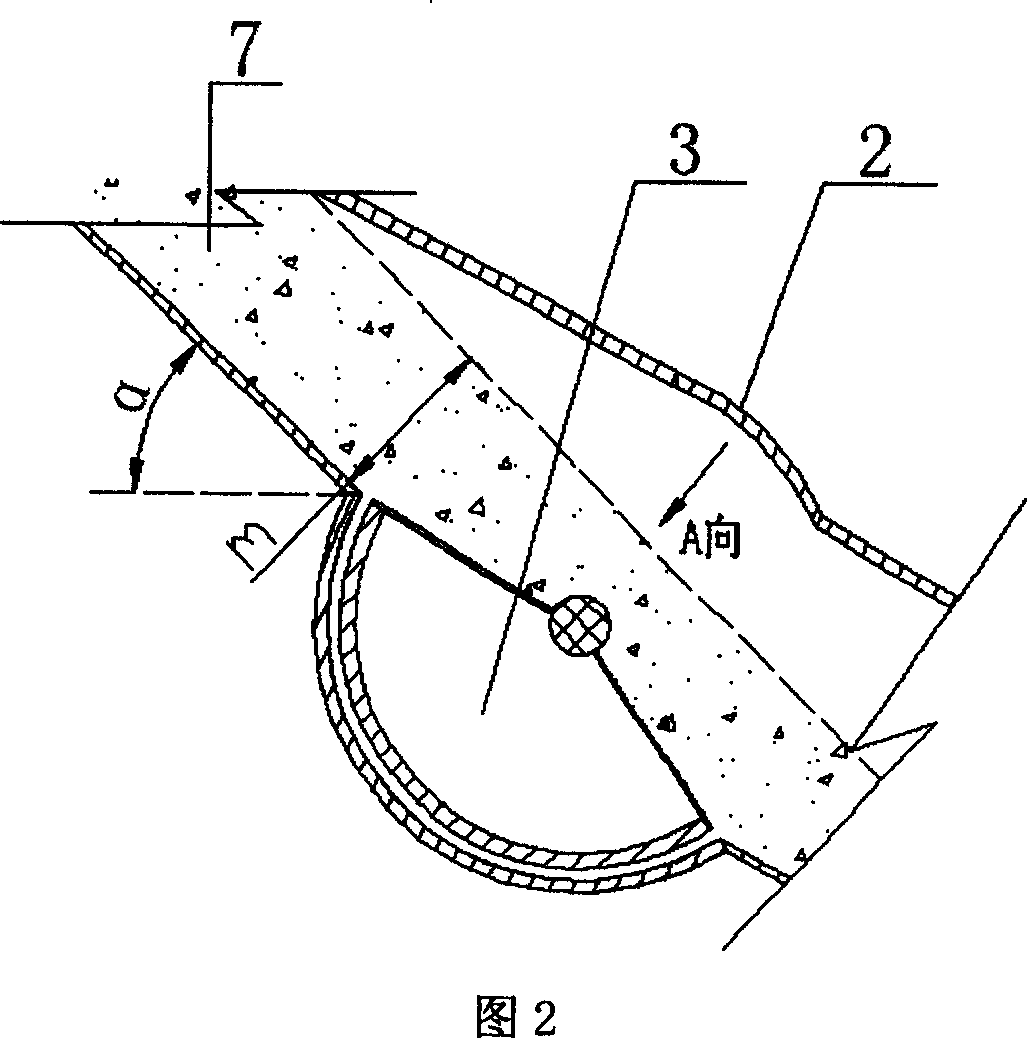

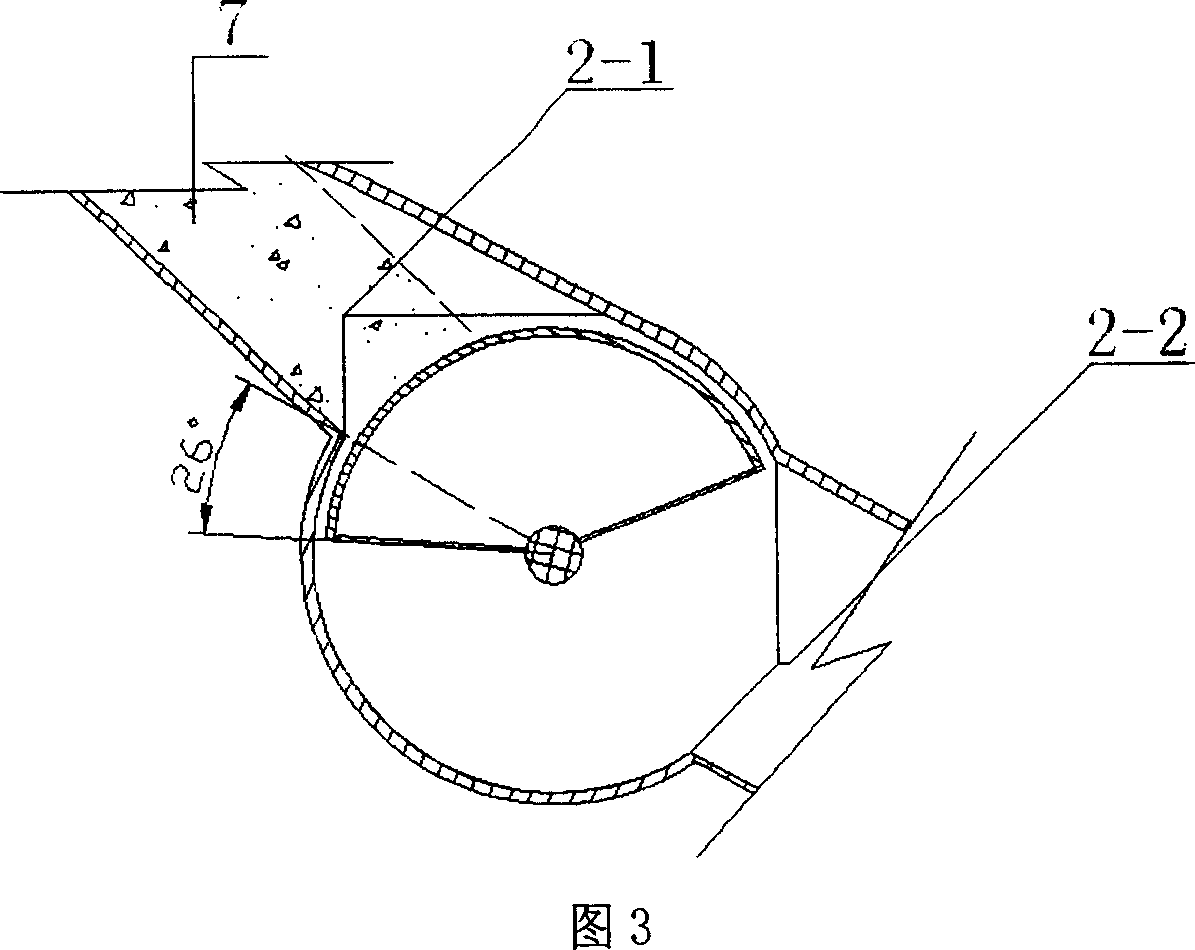

[0016] Embodiment of the present invention is such as Fig. 1, and feed chute 1 adopts carbon steel plate (Q235-A) welding system, and chute angle is 45 °. The rotary valve housing 2 and the spool 3 are made of wear-resistant 45# steel. The ribs 3-4 of the valve core 3 adopt two rectangular flat plates, the two long sides of the ribs 3-4 are respectively welded to the shaft 3-1 and the arc sealing surface 3-3, and the two short sides of the ribs 3-4 are connected to the end plate 3 -2 welding. The outer surface of the arc sealing surface 3-3 and the inner surface of the housing 2 are precision machined, and the control gap is about 0.8 mm. The angle between ribs 3-4 is 150°. The upper arc angle of the rotary valve housing 2 is 45°, and the lower arc angle is 150°. The driving mechanism 5 adopts a pneumatic actuator. The solid material in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com