Minimum gas high precision collection device and its usage method

A collection device and trace gas technology, applied in the field of test analysis, can solve the problems of high maintenance cost, complicated equipment, long time, etc., and achieve the effects of easy processing, improved analysis accuracy and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

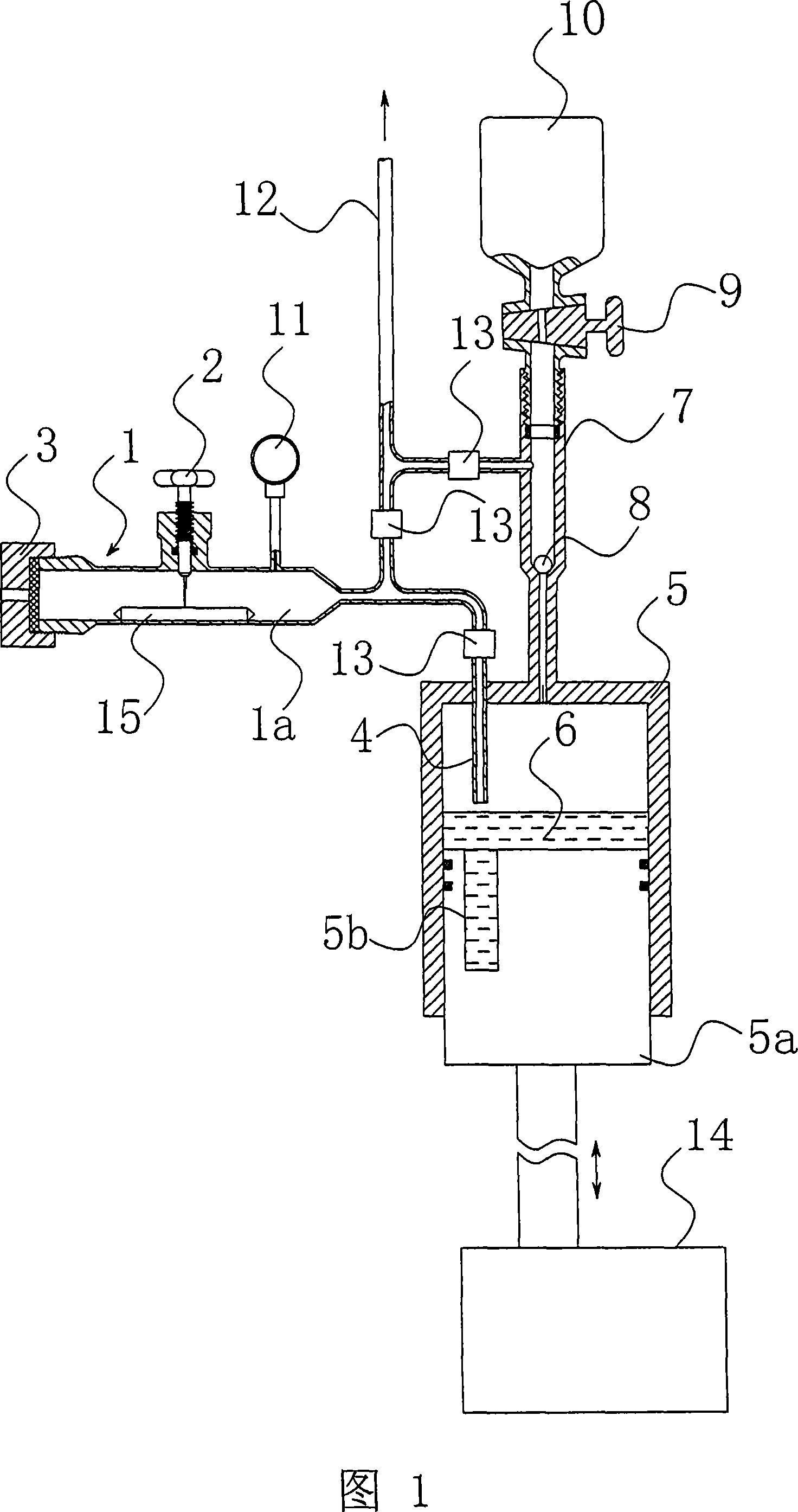

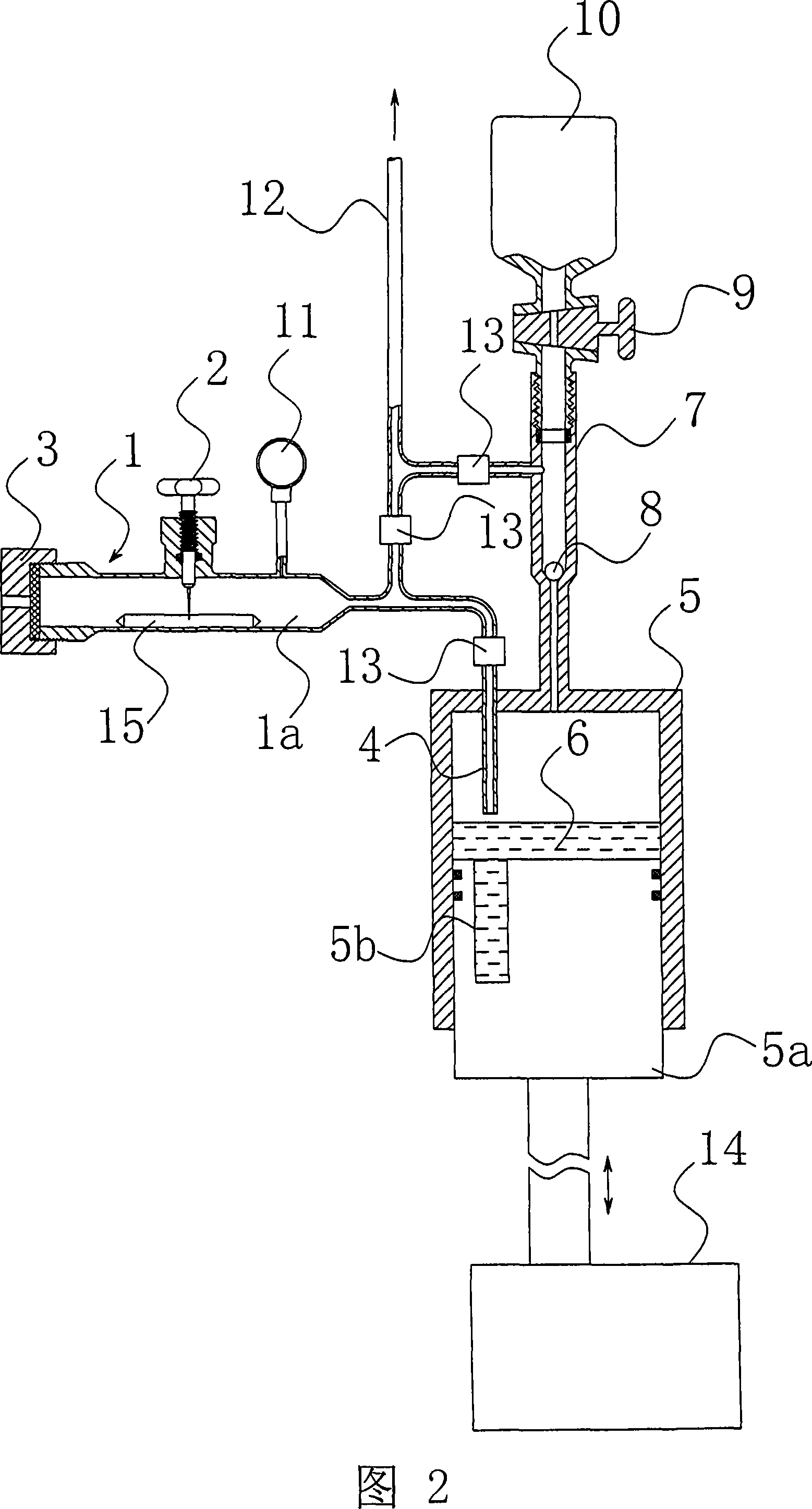

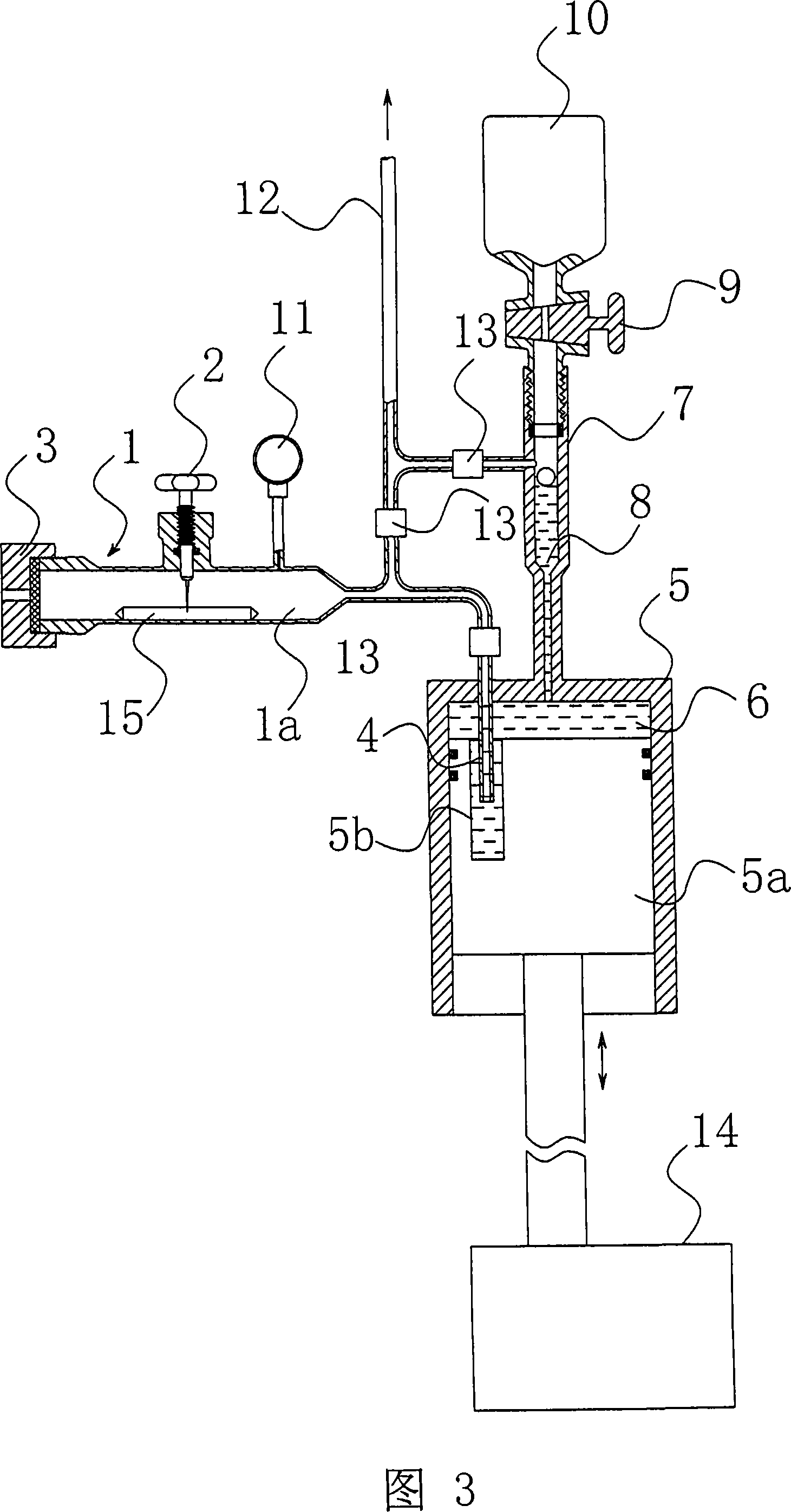

[0020] Referring to shown in Fig. 1, the high-precision collecting device of trace gas of the present invention comprises a tube body 1, the inside of the tube body 1 is a gas chamber 1a, a needle valve 2 is provided on the tube body 1, and at the left end of the tube body 1 A sealing pressure cap 3 is provided, and a gas delivery pipe 4 is provided in the gas chamber 1a of the pipe body 1 to communicate with the vertically arranged cylinder 5. The piston 5a of the cylinder 5 is located below and is connected to the reciprocating drive mechanism 14. The reciprocating drive mechanism 14 can adopt existing There are motor / eccentric wheel mechanisms, gear / rack transmission mechanisms, etc. in the art; mercury liquid 6 is filled in the cylinder 5, and a separation pipe 7 with a tapered lower part is connected to the upper part of the cylinder 5, and the separation pipe 7 is provided with a seal Steel ball 8, the top of separation pipe 7 is connected with sample bottle 10 with valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com