Upper shining type organic shining diode transparent touch screen

A technology of light-emitting diodes and touch screens, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of complicated preparation methods, poor sensitivity of resistive touch elements, and shortened service life of organic light-emitting displays. and other problems, to achieve the effect of accurate and sensitive induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

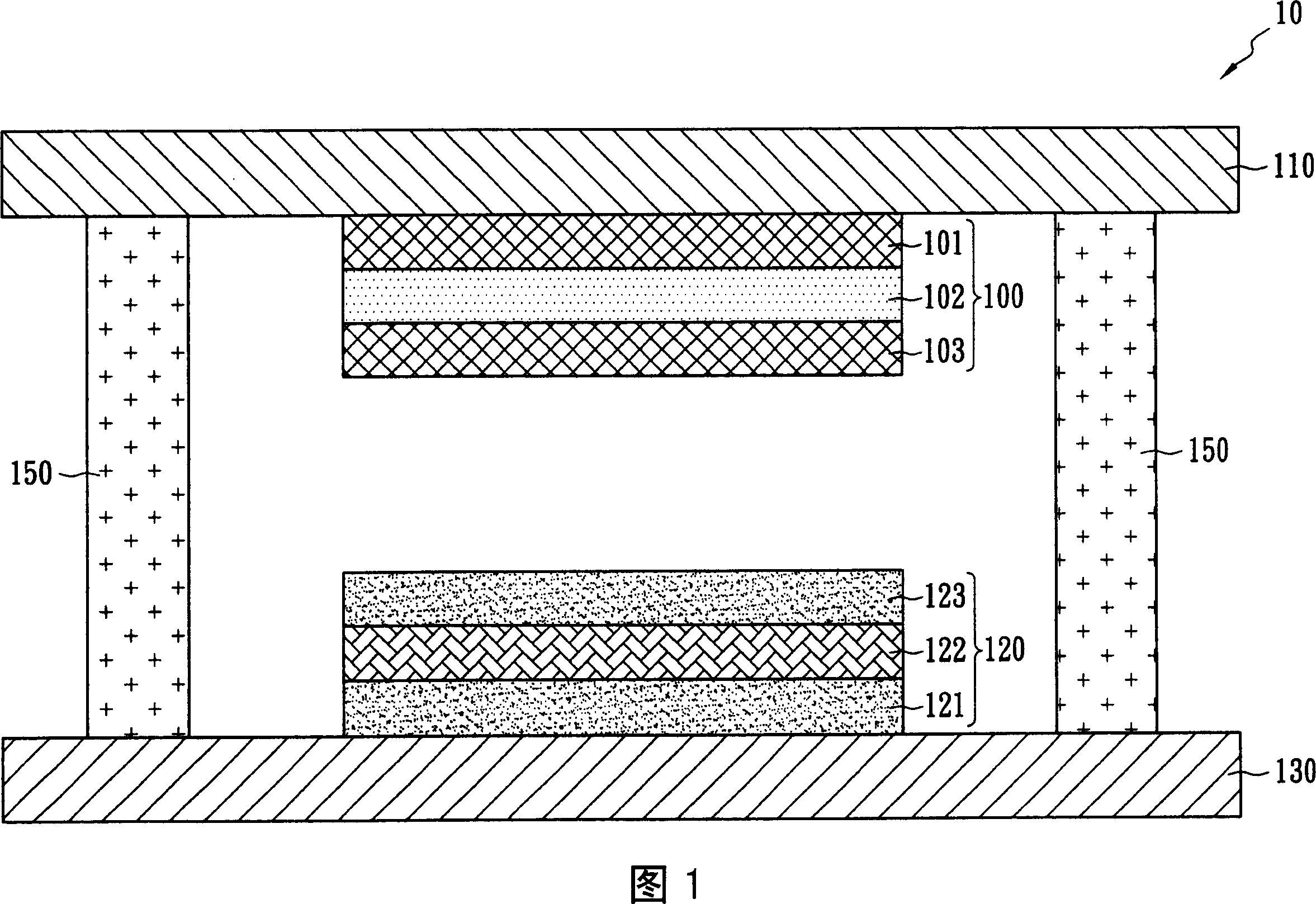

[0029] FIG. 1 is a schematic cross-sectional view of a transparent touch screen 10 with upward emitting organic light emitting diodes according to a first embodiment of the present invention. The transparent touch screen 10 includes a substrate 130 , a top cover 110 , an OLED device 120 , a capacitive touch element 100 and a sealant layer 150 .

[0030] The organic light emitting diode device 120 is stacked on the substrate 130, the capacitive touch element 100 is stacked on the surface of the upper cover 110, the sealant layer 150 is respectively bonded to the substrate 130 and the upper cover 110, The OLED device 120 is sealed in a closed space.

[0031] In the capacitive touch element 100 , a first transparent conductive layer 101 , an insulating layer 102 and a second transparent conductive layer 103 are sequentially formed on the upper cover 110 . However, the structure of the capacitive touch element is not limited to this embodiment, and the second transparent conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com