Method of making light emitting device with silicon-containing encapsulant

A manufacturing method and a technology of a light-emitting device, which can be applied to circuits, electric solid-state devices, semiconductor devices, etc., and can solve problems such as lead wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

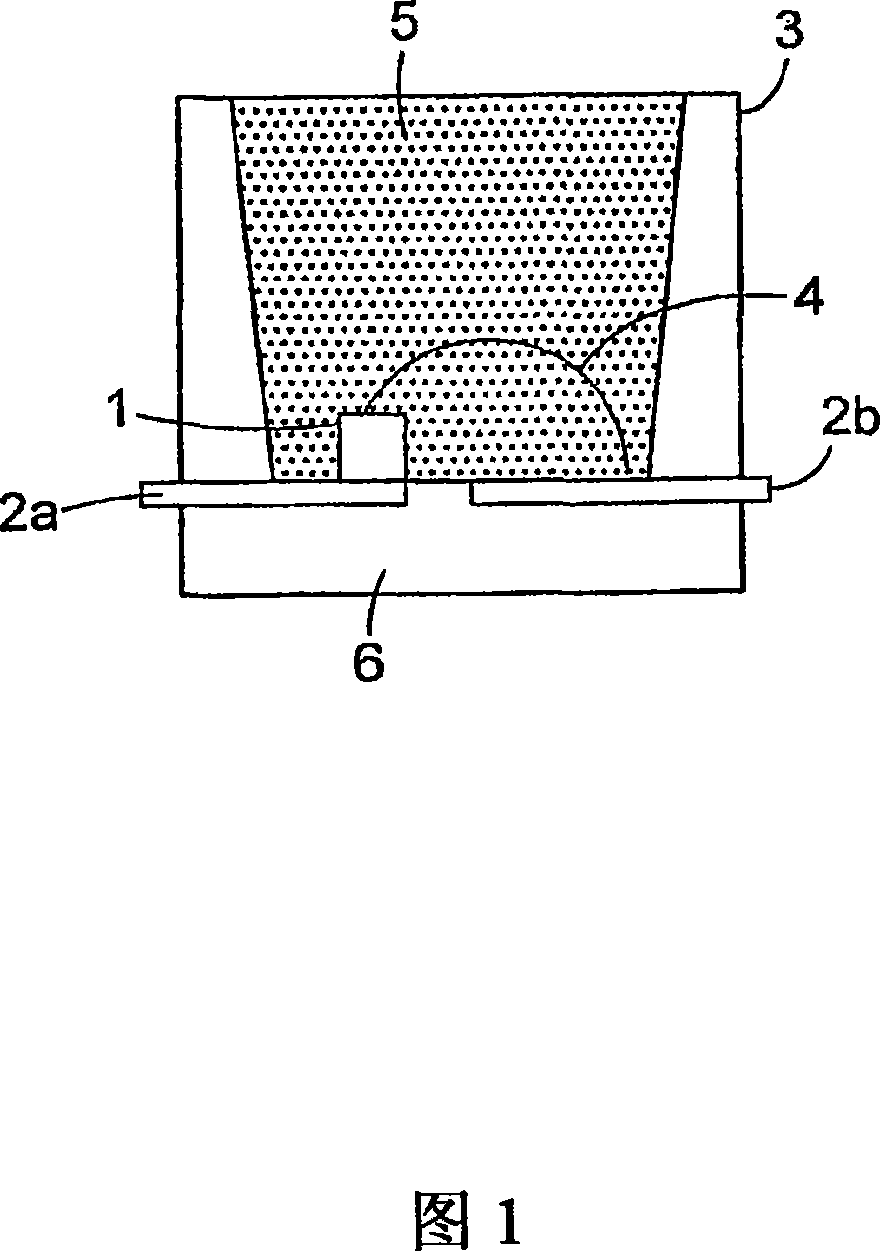

Image

Examples

Embodiment 1

[0059] Example 1: Visible light curing

[0060] Prepare in a 35 mL brown bottle from 10.00 g (milli-equivalent weight of olefin = 3.801 g) of organopolysiloxane prepared as described in the previous paragraph and 0.44 g (milli-equivalent weight of Si-H = 0.111 g) (CH 3 ) 3 SiO-[Si(CH 3 ) 2 O] 15 -[SiH(CH 3 )O] 25 -Si(CH 3 ) 3 (SYL-OFF(R) 7678 from Dow Corning Company). By adding 22.1mg Pt(acac) 2 (wherein acac is acetylacetonate, purchased from Aldrich Chemical Company) dissolved in 1.00mL CH 2 Cl 2Catalyst stock solutions were prepared in . A 100 [mu]L aliquot of this catalyst stock was added to the silicone mixture. The final formulation corresponds to a ratio of aliphatic unsaturation to silicon-bonded hydrogen of 1.5 and contains about 100 ppm platinum.

[0061] About 2 mg of the above final formulation was placed in the LED assembly. The LED was illuminated at 20 mA for 2.5 minutes. The sealed device was left to stand for an additional 5 minutes. The seala...

Embodiment 2

[0062] Embodiment 2: UV light curing

[0063] A sealed LED device was fabricated and evaluated in the same manner as described in Example 1, except that 21.1 mg of CpPt(CH 3 ) 3 , without using 22.1mg Pt(acac) 2 , and the difference is that the UV lamp is used to irradiate at 365nm, wherein the CpPt(CH 3 ) 3 was prepared according to the method described by Boardman et al. (Magn. Reson. Chem., 30, 481 (1992)). The efficiency of the device was measured to increase from 8.9% before sealing to 11.6% after sealing.

Embodiment 3

[0066] Example 3: Visible light curing

[0067] Prepared from 10.00 g (milliequivalent weight of olefin = 1.46 g) of vinylsiloxane base polymer H in a 35 mL brown bottle 2 C=CH-Si(CH 3 ) 2 O-[Si(CH 3 )(C 6 h 5 )O] n -Si(CH 3 ) 2 -CH=CH 2 (PMV-9925, produced by Gelest Company) and 1.64g (mequivalent weight of Si-H = 0.16g) silicone crosslinking agent (CH 3 ) 2 SiO-[SiH(CH 3 )O] m -[Si(CH 3 )(C 6 h 5 )O] n -Si(CH 3 ) 2 A silicone mixture consisting of H (HPM-502, produced by Gelest Company). Prepare Pt(acac) according to the method described in Example 1 2 in CH 2 Cl 2 , and a 100 μL aliquot of the resulting solution was added to the siloxane mixture. The final formulation corresponds to a ratio of aliphatic unsaturation to silicon-bonded hydrogen of 1.5 and contains about 100 ppm platinum.

[0068] About 2 mg of the above final formulation was placed in the LED assembly. The LED was illuminated at 20 mA for 2.5 minutes and then left to stand for an addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com