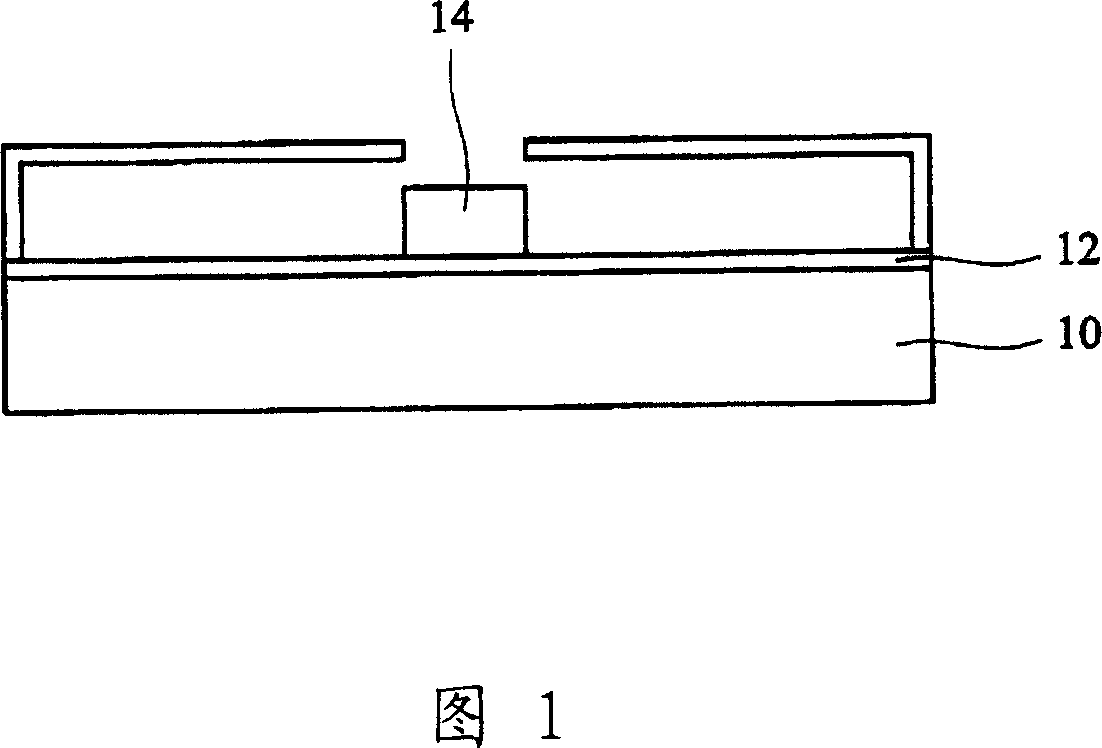

Fluid ejecting device and method for making the same

A technology of fluid injection and production methods, which is applied in printing and other directions, can solve the problems of not effectively improving the heat utilization rate, increasing the power of the injection device, accelerating the dissipation of heat energy, etc., and achieving a significant effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

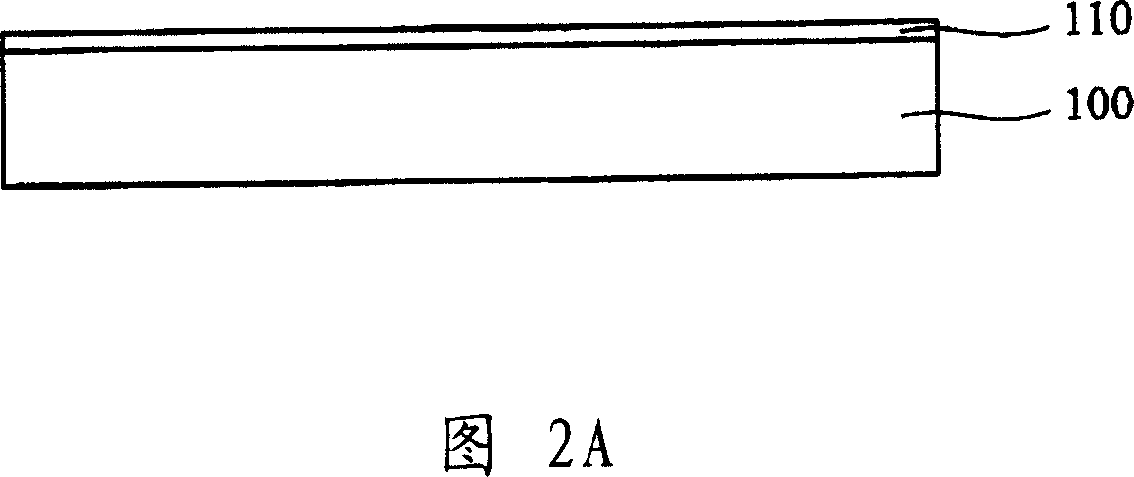

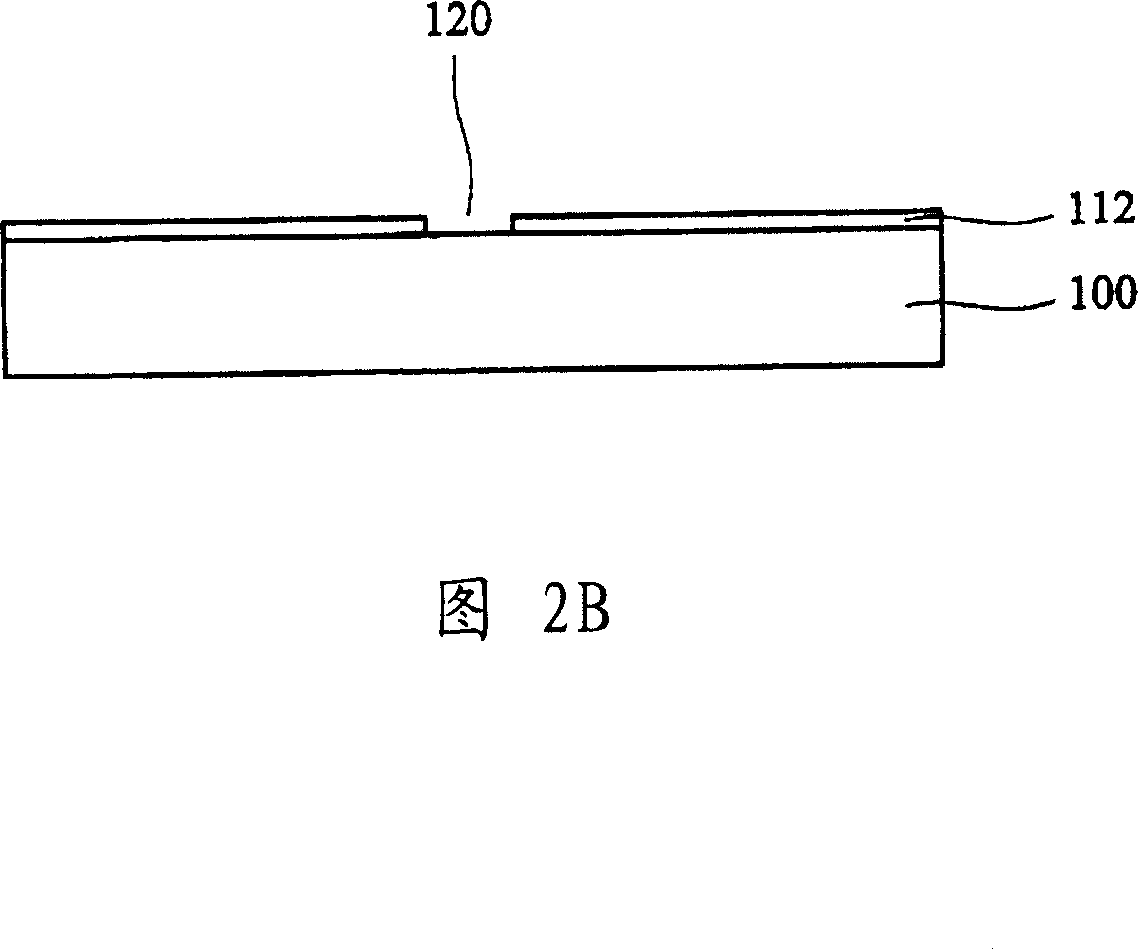

[0039] Hereinafter, the present invention will be described in detail with examples and accompanying drawings. In the drawings or descriptions, similar or identical parts use the same symbols. In the drawings, the shape or thickness of the embodiments may be exaggerated to simplify or facilitate labeling. Part of the elements in the drawings will be described in the description. It is to be understood that elements not shown or described may have various forms known to those skilled in the art. Furthermore, when it is stated that a layer is on a substrate or another layer, the layer may be directly on the substrate or another layer, or there may be an intervening layer therebetween.

[0040] 2A-2H are schematic cross-sectional views showing a method of fabricating a fluid ejection device according to an embodiment of the present invention. First please refer to FIG. 2A, a shielding layer 110 is formed on a first substrate 100, wherein the first substrate is preferably made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com