Method for synthesizing star amphiphilic rubber

A hybrid arm and rubber technology, used in the fields of rubber synthesis and polymer compound synthesis, can solve the problems of cold flow and processing performance, difficult coupling, and the influence of adding methods, etc., to achieve good wet skid resistance, good cold resistance and Abrasion resistance, effect of low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

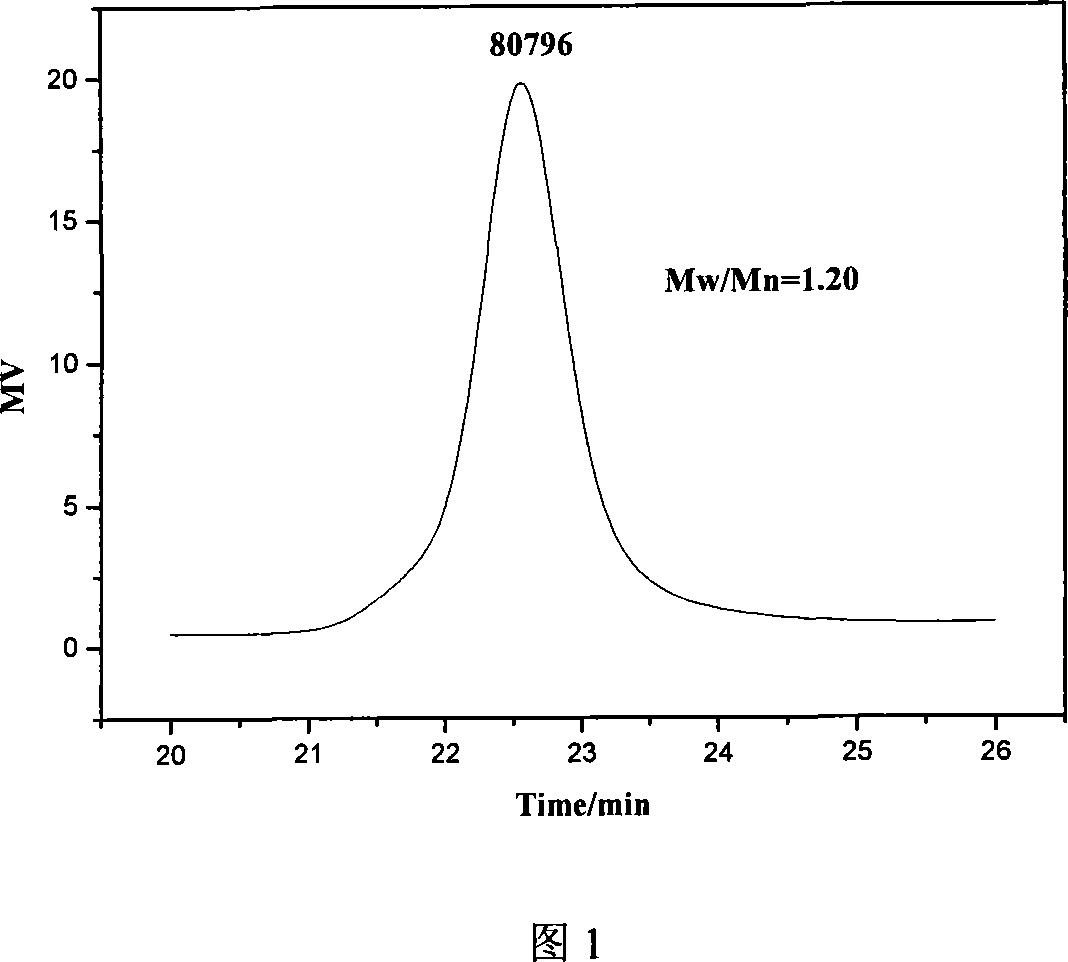

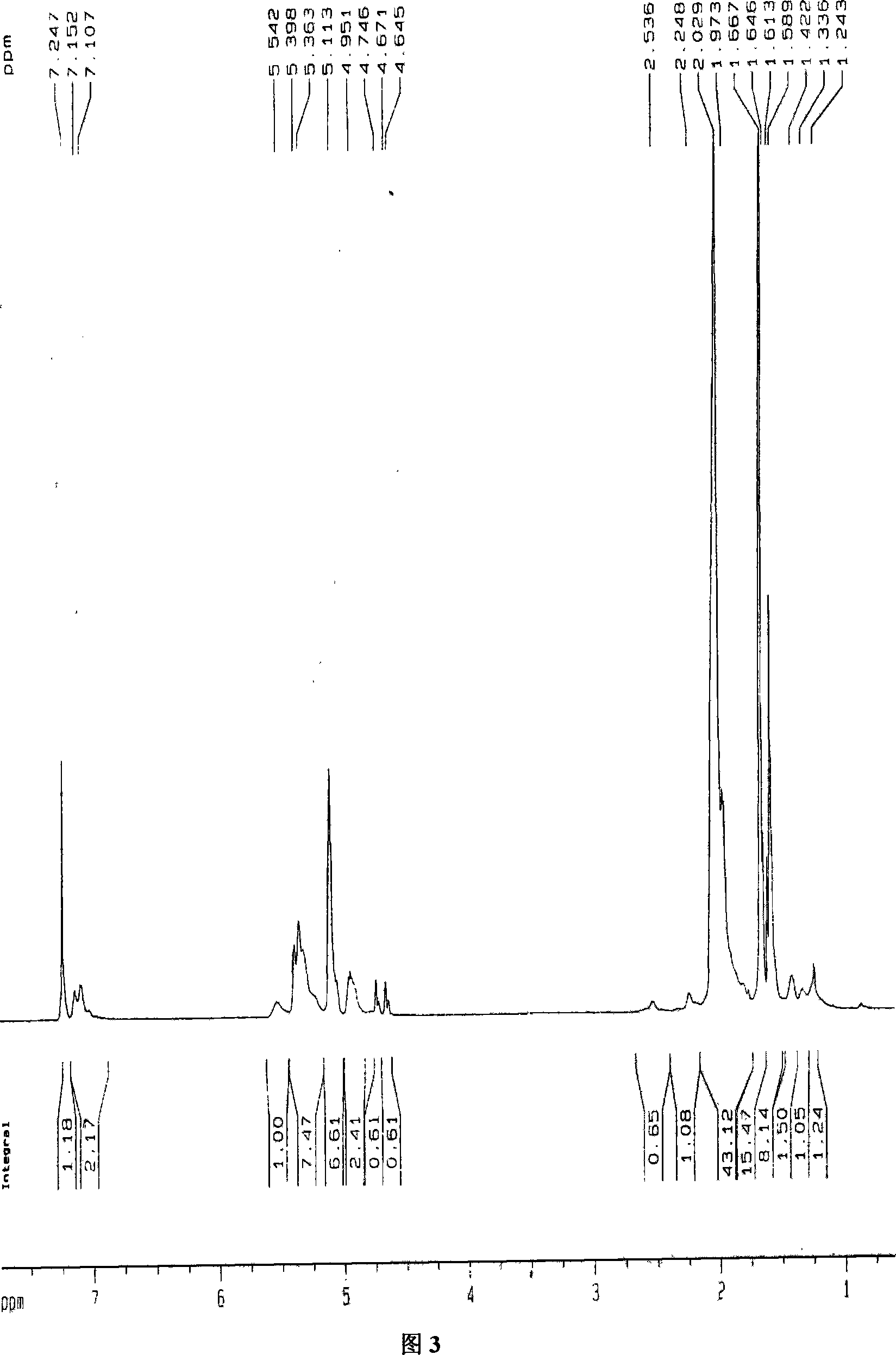

Embodiment 1

[0032] Feeding tubes, absorption bottles, etc. are treated according to the method of anion polymerization to remove impurities, and they are used under nitrogen protection for standby. The 2L polymerization kettle was evacuated and filled with nitrogen repeatedly three times to maintain the nitrogen atmosphere. Add 700 ml of isoprene cyclohexane solution (concentration: 10 g isoprene / 100 ml hexane) into the absorption bottle, add 0.875 mmol of tetrahydrofuran to adjust the structure, shake well, add 0.875 mmol of n-butyllithium to initiate , Add the solution to the reactor and polymerize at 70°C.

[0033] After polymerization for 1 hour, 0.35 mmol of divinylbenzene was added to the kettle for coupling after monomer conversion was complete.

[0034] After 1.5 hours, 700 ml of cyclohexane solution (concentration of 10 g monomer / 100 ml hexane) with 50 / 50 mass ratio of butadiene / styrene containing 0.4375 mmol of tetramethylethylene diammonium was added to the reactor Polymeriza...

example 2

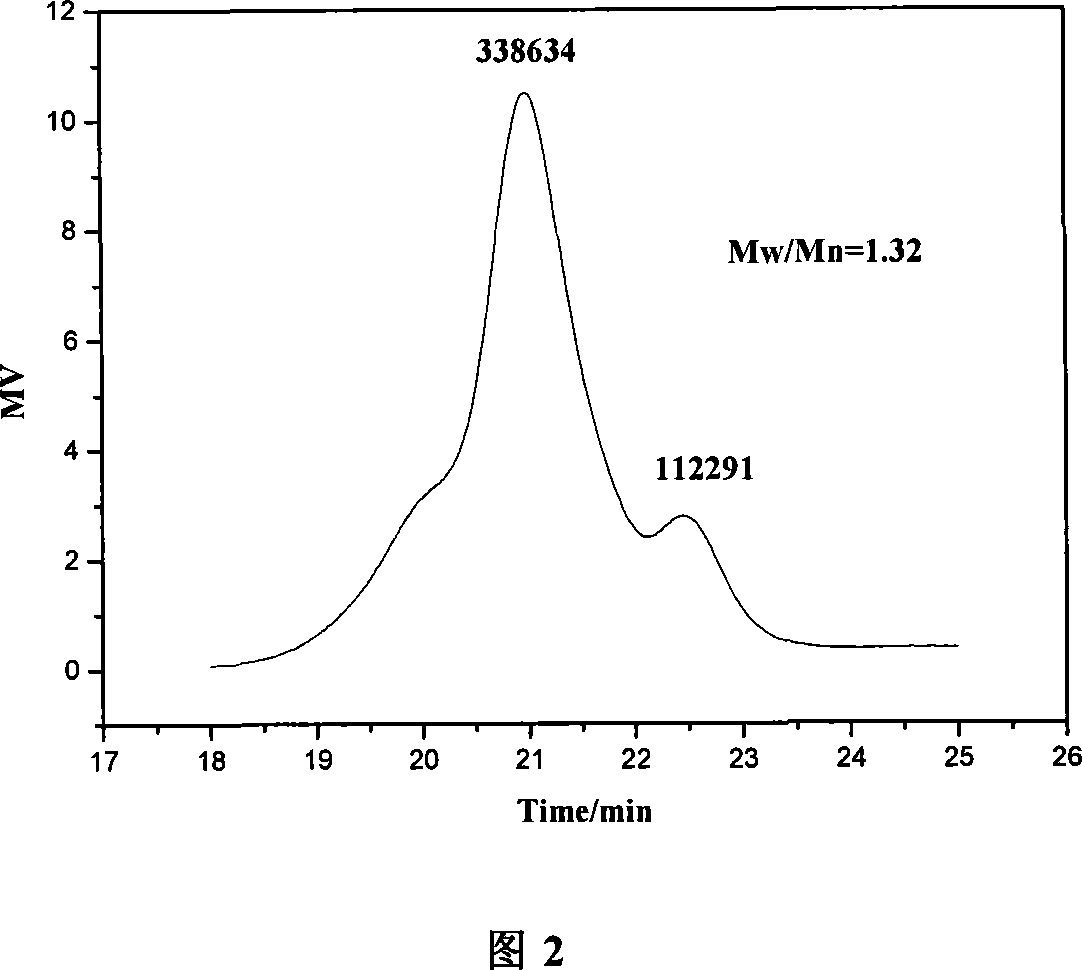

[0038] Feeding tubes, absorption bottles, etc. are treated according to the method of anion polymerization to remove impurities, and they are used under nitrogen protection for standby. The 2L polymerization kettle was evacuated and filled with nitrogen repeatedly three times to maintain the nitrogen atmosphere. Add 700ml of cyclohexane solution of isoprene to the absorption bottle (concentration is 10g isoprene / 100ml cyclohexane, hexane mixture), add 0.875 mmol of tetrahydrofuran to adjust the structure, shake well, add 0.875 mmol Initiated by n-butyllithium, the solution was added to the reactor and polymerized at 90°C.

[0039] After polymerization for 2 hours, 0.44 mmol of divinylbenzene was added to the kettle for coupling after monomer conversion was complete.

[0040] After 1 hour, 700ml of a cyclohexane solution (concentration of 10g monomer / 100ml cyclohexane and hexane mixture) with a mass ratio of butadiene / styrene containing 35 mmoles of tetrahydrofuran was added t...

example 3

[0044] Feeding tubes, absorption bottles, etc. are treated according to the method of anion polymerization to remove impurities, and they are used under nitrogen protection for standby. The 2L polymerization kettle was evacuated and filled with nitrogen repeatedly three times to maintain the nitrogen atmosphere. Add 700ml of isoprene cyclohexane solution (concentration: 10g isoprene / 100ml cyclohexane) into the absorption bottle, add 0.875 mmol of tetrahydrofuran to adjust the structure, shake well, add 0.875 mmol of n-butyllithium Initiate, add the solution to the reactor and polymerize at 50°C.

[0045] After polymerization for 1.5 hours, 0.66 millimoles of divinylbenzene was added to the kettle for coupling after the conversion of the monomers was complete.

[0046] After 0.5 hour, the butadiene / styrene mass ratio that will contain 0.088 mmol sodium lauryl sulfate, 0.088 mmol pentamethyldivinyl triamine is the cyclohexyl solution (concentration is 10g) of 75 / 25 Monomer / 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com