Modified natural rubber composite material with low rolling resistance and wet skid resistance and preparation method thereof

A technology of natural rubber and composite materials, which is applied in the field of low rolling resistance wet slip modified natural rubber composite materials and its preparation, which can solve the problems of affecting the reinforcement effect, easy agglomeration, weak interface interaction, etc., and achieve wet slip resistance Improvement, low rolling resistance, rolling resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

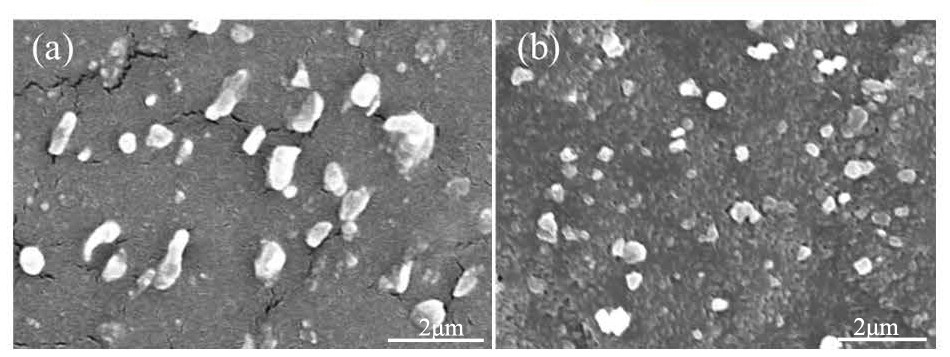

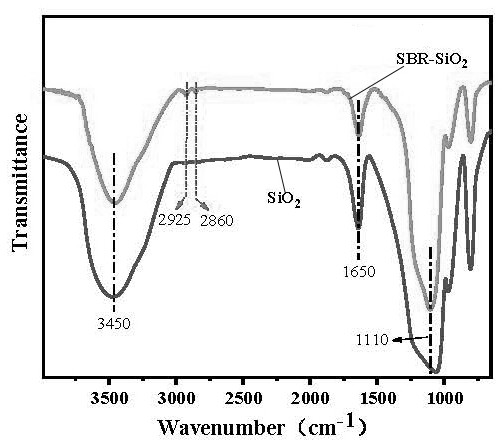

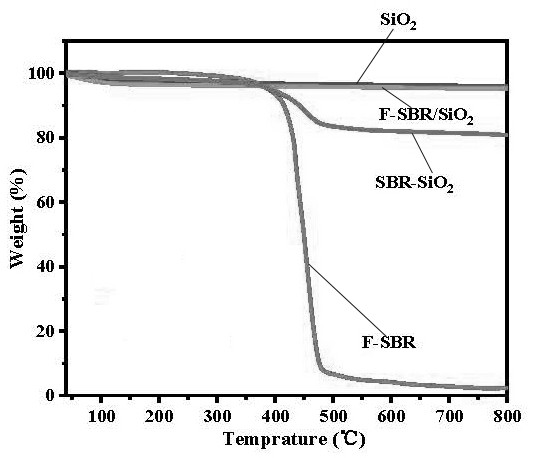

Image

Examples

Embodiment 1-4

[0046] Embodiment 1-4 Preparation of low rolling resistance wet slip modified natural rubber composite material:

[0047]Prepare according to the formula in Table 1 as follows:

[0048] ① Prepare the prepared modified silica particles in proportion by mass to prepare an aqueous solution. After ultrasonication for 15 minutes, add it to natural rubber latex with a solid content of 60%. After mechanical stirring for 30 minutes, calcium chloride solution is used for demulsification. After drying in an oven at 70°C, the master batch is obtained;

[0049] ②Under the conditions of 90°C and 40rpm, masticate the dry masterbatch obtained in step ① in an internal mixer, and add 5 parts by mass of zinc oxide, 2 parts of stearic acid, 1.5 parts of Vulcanization accelerator NOBS, 1 part of anti-aging agent 4010NA and 1 part of antioxidant RD, knead for 5 minutes, and discharge the rubber compound;

[0050] ③ Adjust the cavity temperature of the internal mixer to 110°C, put the rubber comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com