Electrically driven sucking precise seeder

A technology of air-suction and seed metering device, which is applied in the direction of interval quantitative sowing machinery, single seed planter, planter parts, etc. It can solve the problems of limited power and space, complex structure, difficult to simplify, etc., and achieve the reduction of specifications and power demand, omitting the transmission mechanism, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

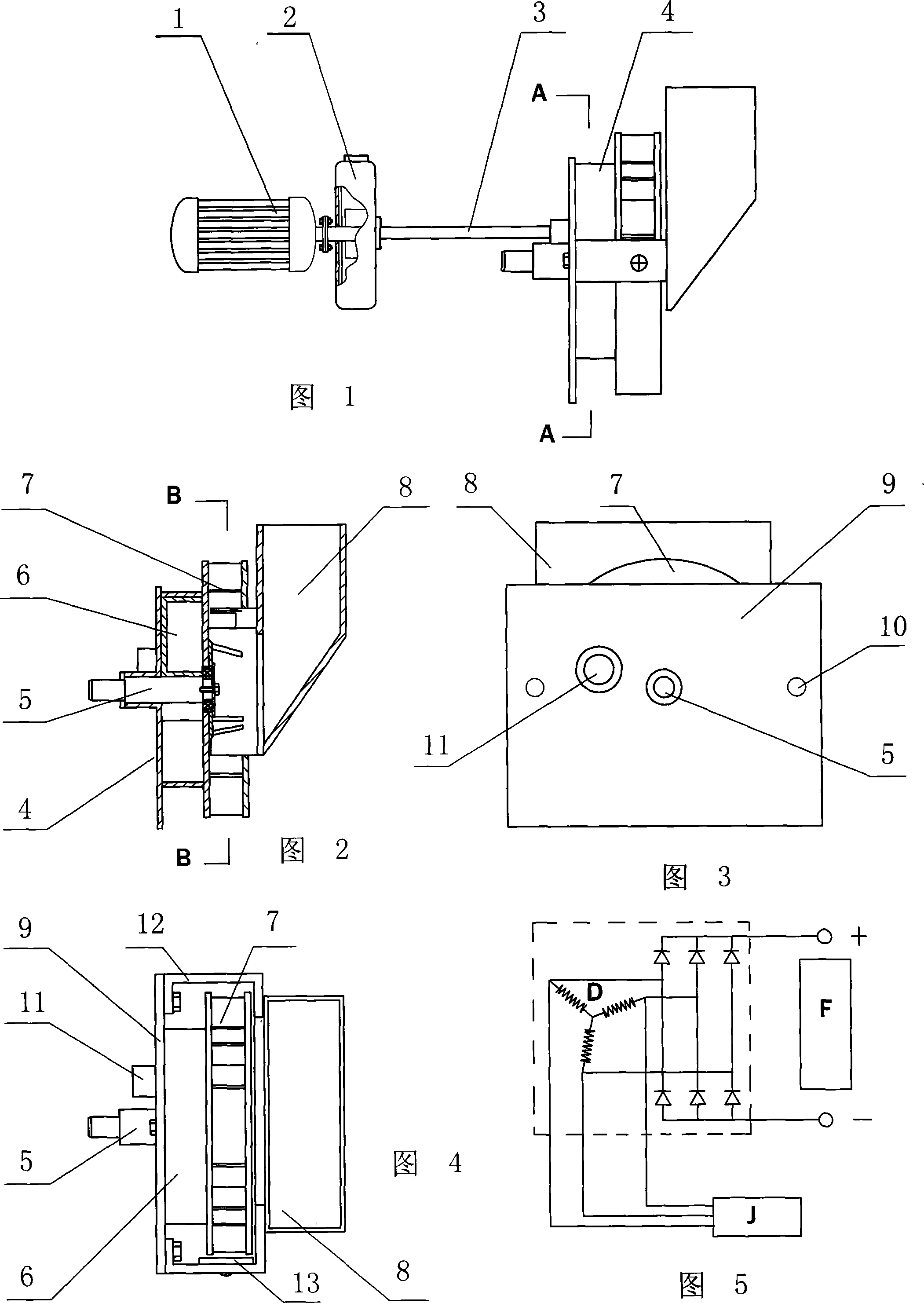

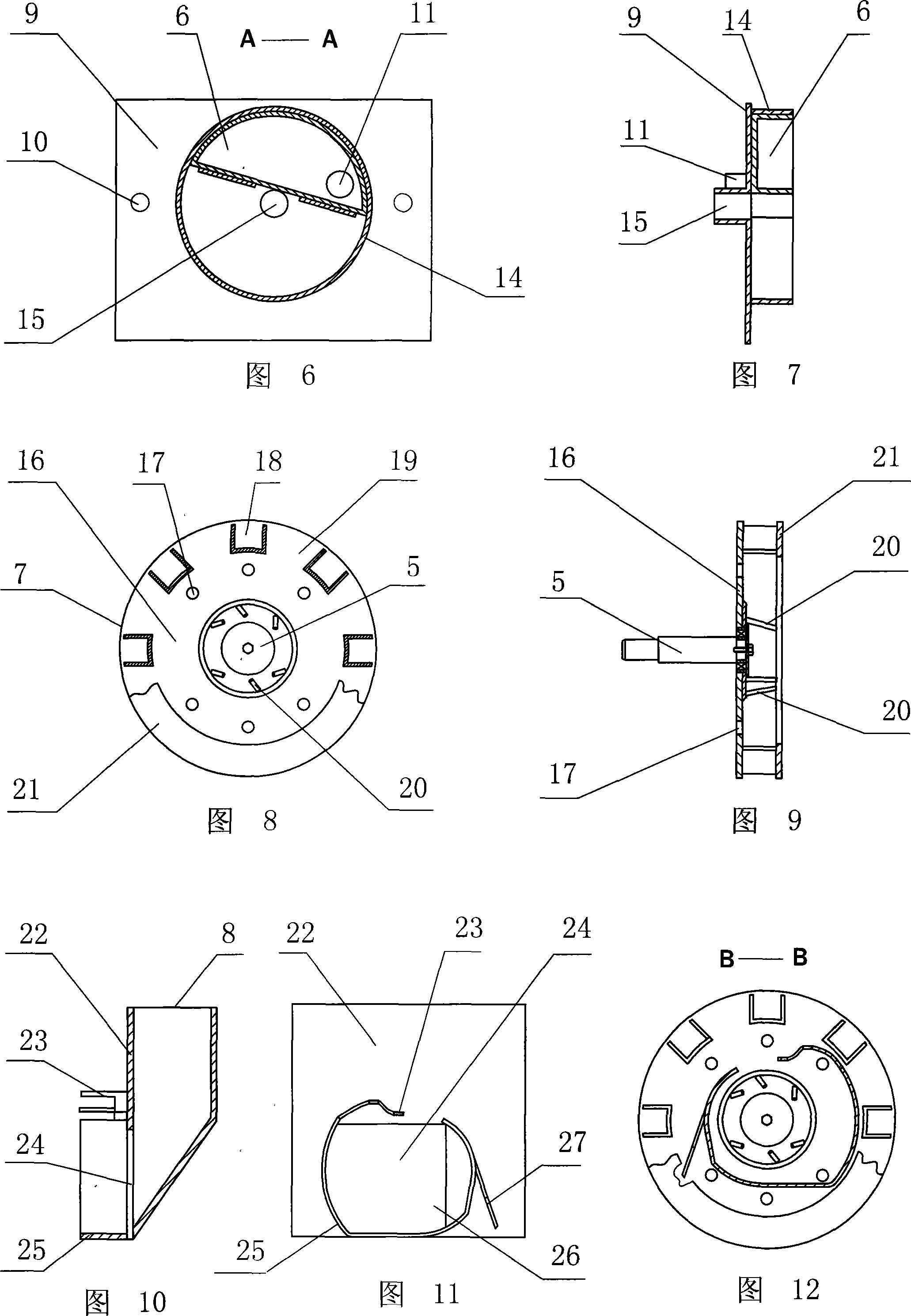

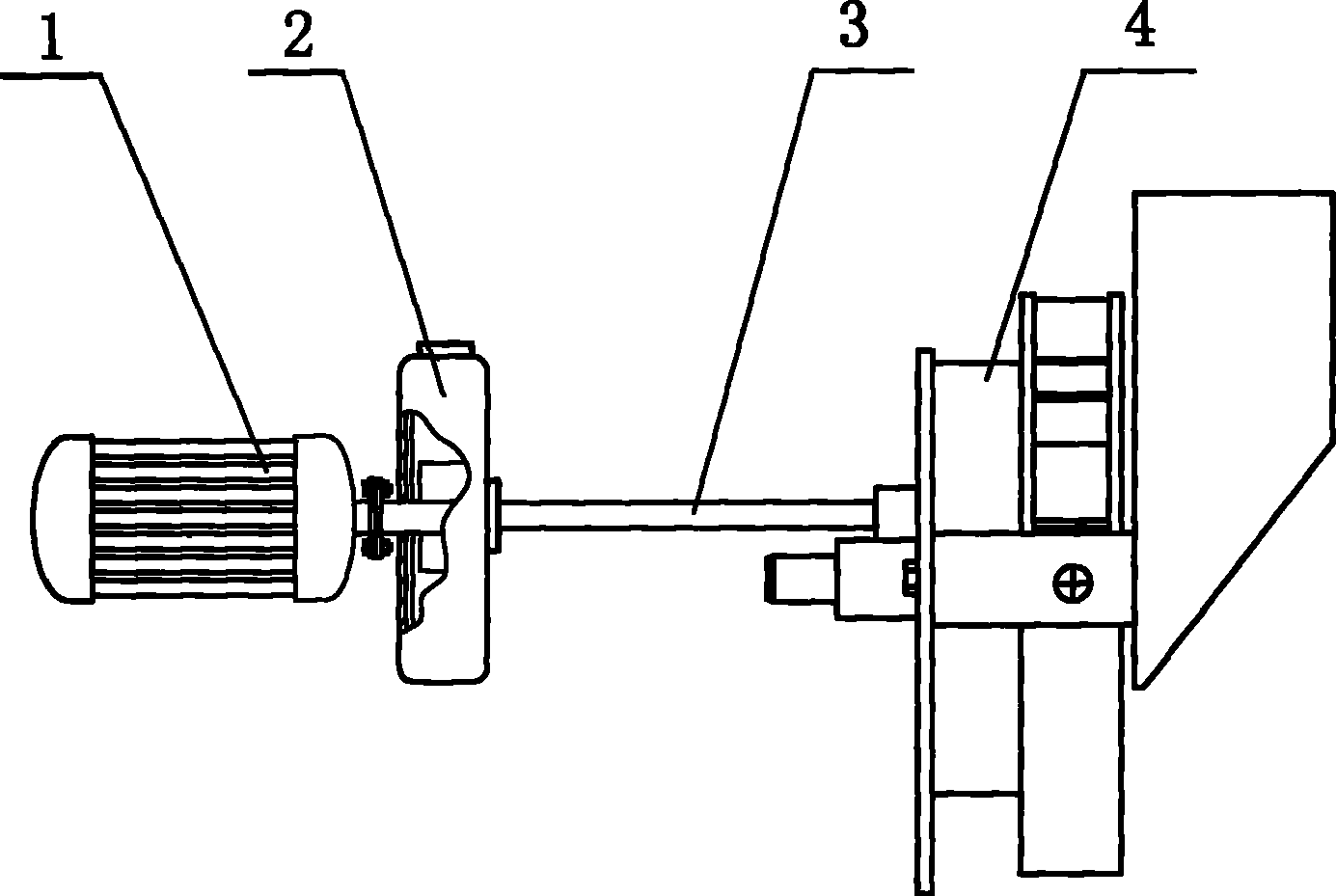

[0026] As shown in FIG. 1 , the motor 1 and the fan 2 are coaxial, and the negative pressure is provided to the seed meter 4 through the suction pipe 3 . It can be seen from Figure 5 that the motor J1 bypasses the battery F, and directly connects with the tractor's self-contained over-frequency generator D before silicon rectification, avoiding the use of complex and expensive DC motors, and obtaining sufficient operating speed. As shown in Figures 2, 3, and 4, the seed meter 4 is composed of a rotating shaft 5, an air suction chamber 6, a seed bowl 7, and a seed box 8. As shown in Figures 6 and 7, the air suction chamber 6 is a A crescent-shaped suction chamber 6 is surrounded above the bottom plate 9, and a through hole is arranged in the suction chamber 6 the inside and is exactly the suction hole 11 connected with the suction pipe 3 outside. On base plate 9 both sides, respectively have a fixing hole 10, as seen in Fig. 4, these two fixing holes 10 respectively connect a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com