Multi-anchoring point antisliding pile adapted to multilayer slide surface and deep sliding face

A technology of multi-anchor and anti-slide piles, which is applied in the direction of sheet pile walls, excavation, construction, etc., can solve the problems of affecting the effect of use, easy to form group anchor effect, pile head stress concentration, etc., and achieve the reduction of piles and anchor cables The length, the position of the anchor cable is superior, and the effect of controlling the deformation of the landslide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

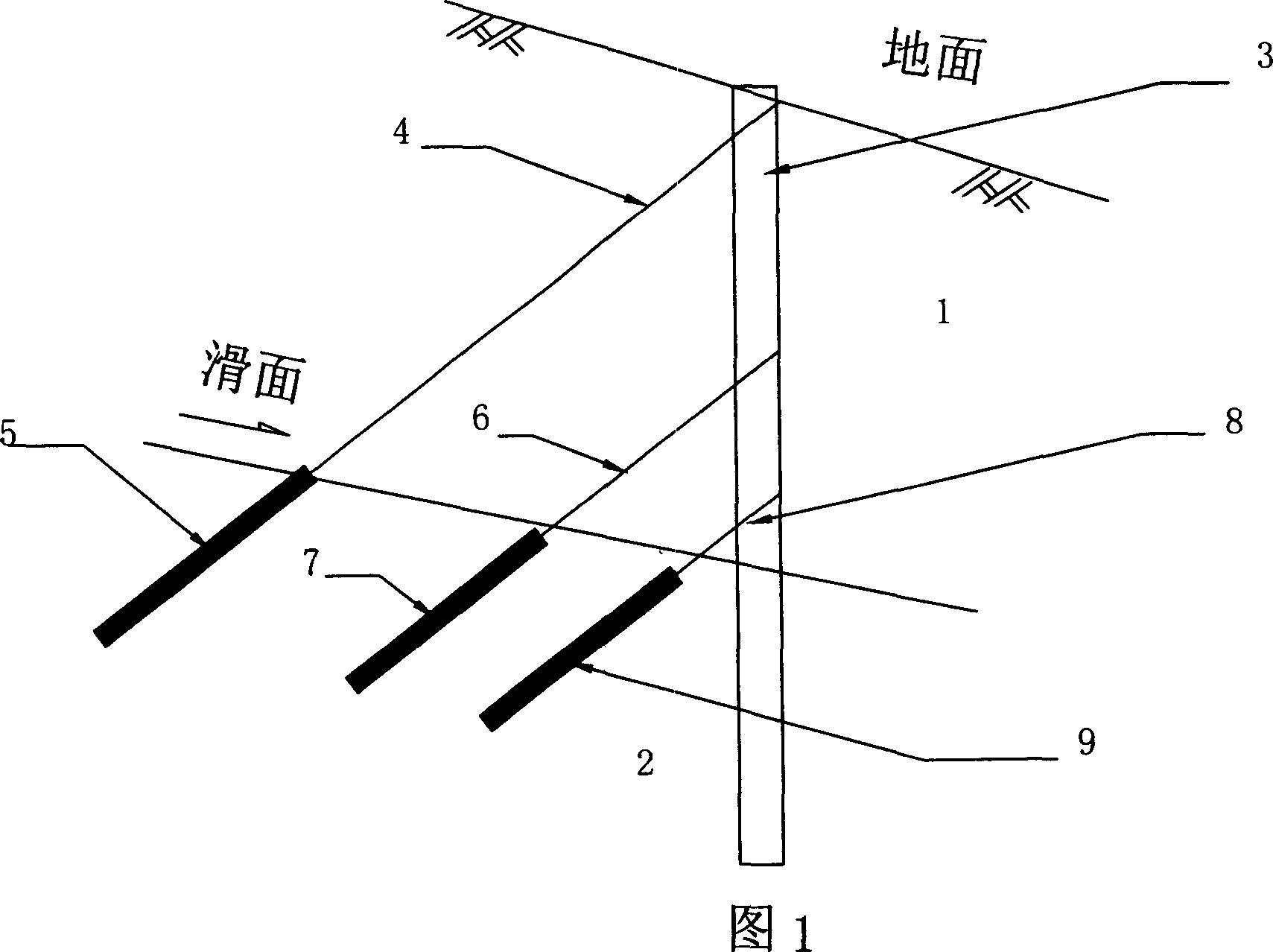

[0024] It can be seen from the example of the present invention provided in Fig. 1 that the pile 3 is located on the cantilever end in the landslide body 1, and three groups of anchor cables are arranged at different elevations. The anchor ends 5, 7 and 9 of each anchor cable are all set in the stable formation 2 below the landslide body 1. It can be seen from Fig. 1 that the anchor cable 1 used is longer, which is basically the same as the prior art, while the anchor cable 6 and the anchor cable 8 are shorter, and they are basically arranged at the maximum bend of the pile. Moment, so the maximum bending moment of the pile can be greatly reduced.

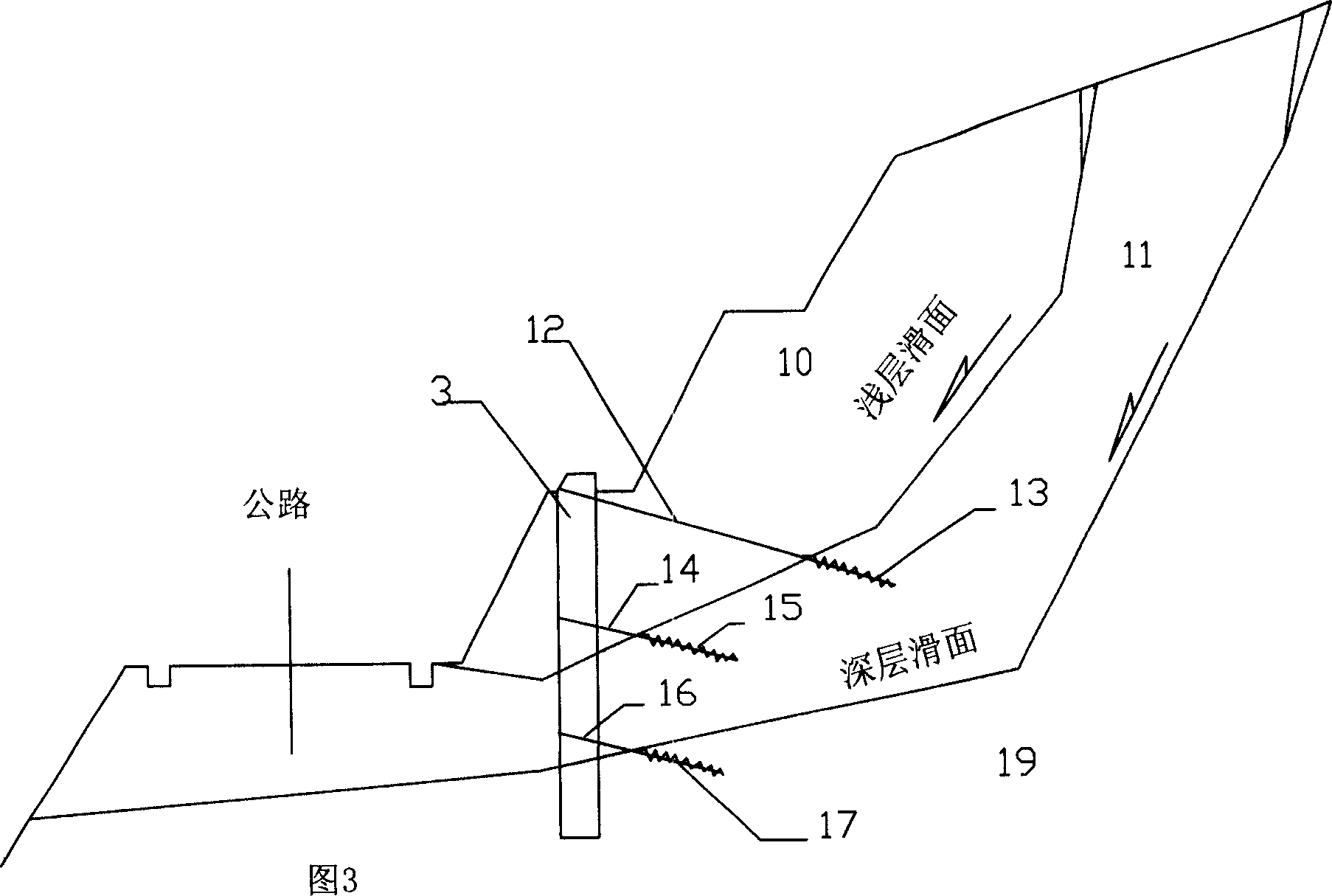

[0025] Take a landslide treatment project in Beijing as an example. The anti-slide pile used in this project is 58m long and the sliding surface depth is 46m. A total of 5 rows of 8 anchor cables are laid along the length of the pile, and the anchor cables use 8 Φ S Made of 15 steel strands, the design tension of each anchor cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com