Method and system for virtual metrology

A technology of measuring and measuring data, which is applied in the field of virtual measurement system, can solve the problems of increasing product cycle time and achieve the effect of improving cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

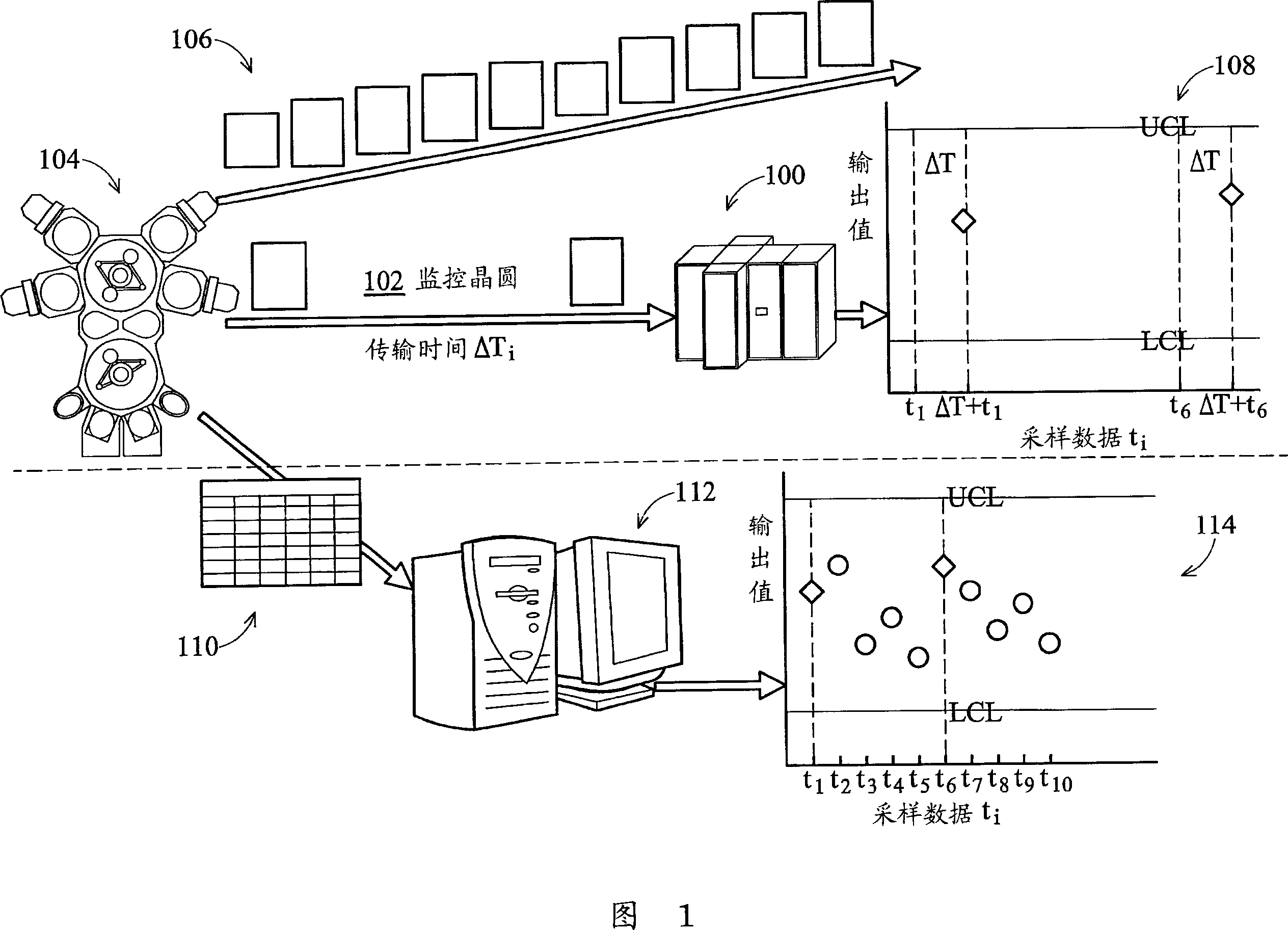

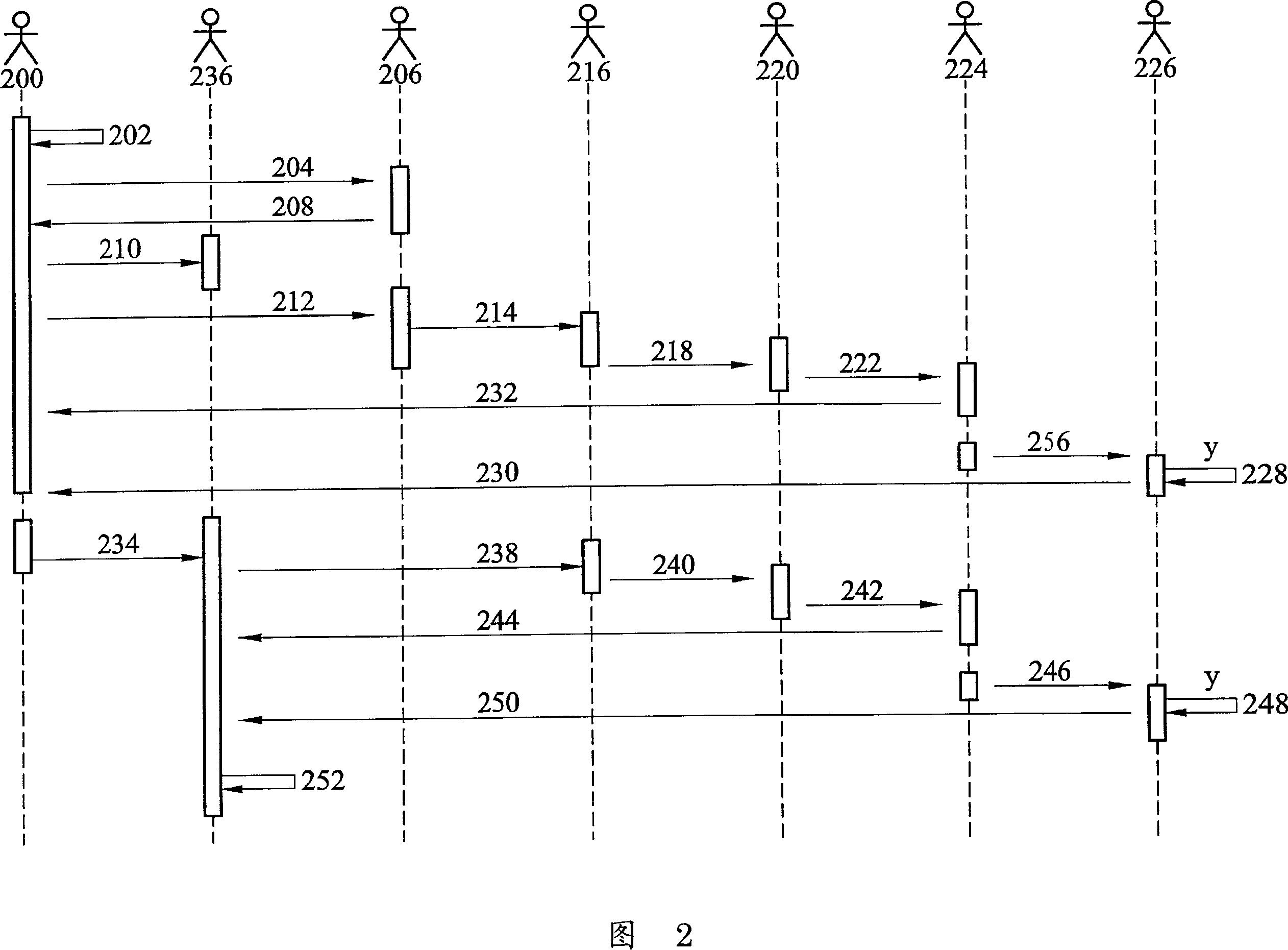

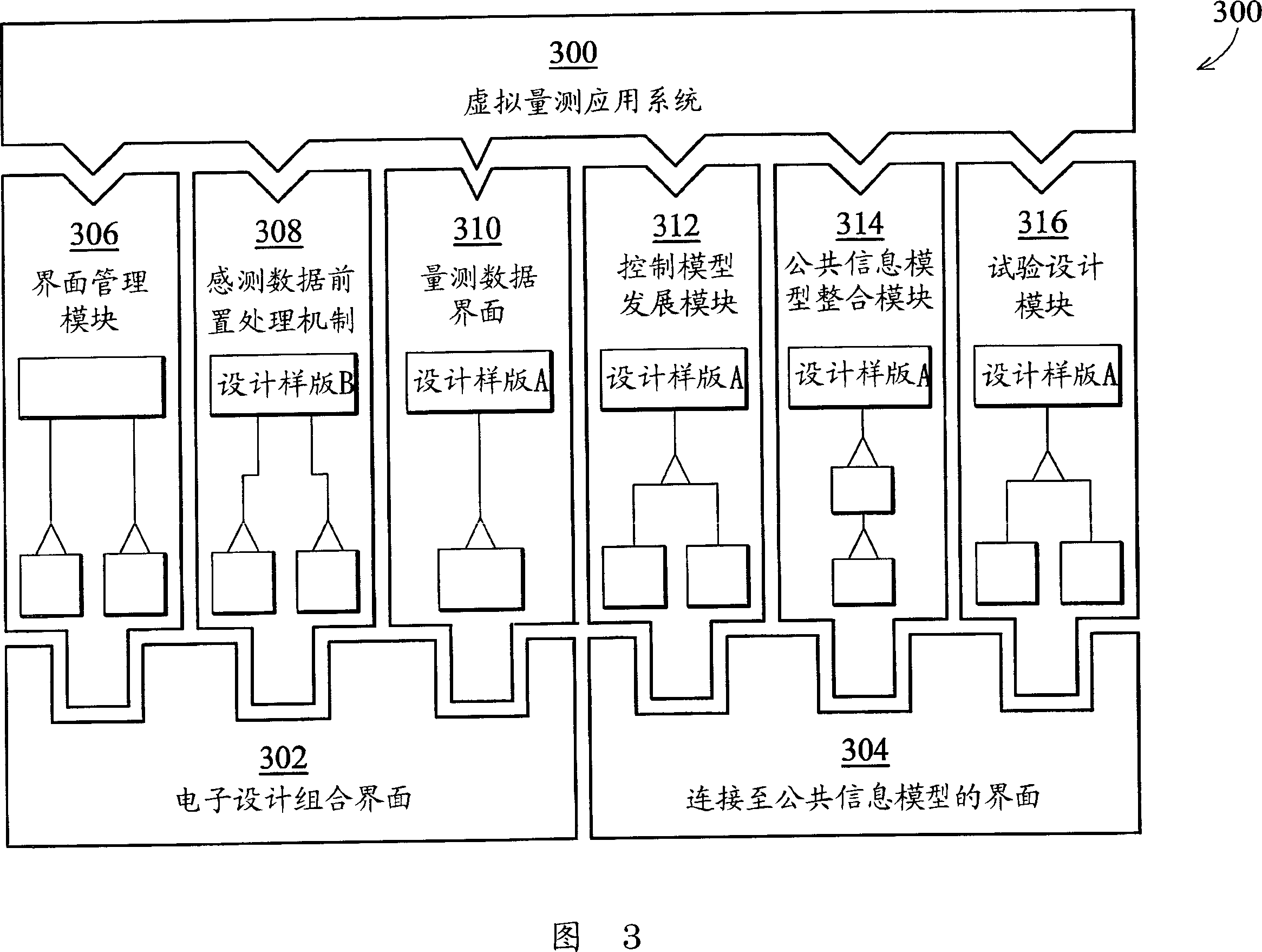

[0028] The present invention discloses a system framework suitable for a virtual measurement application system. The virtual measurement application system can be used to convert system equipment control system information into process and tool performance information of manufacturing equipment. Program and tool performance information is also called forecast data. Combining predictive data with different tools can replace or enhance existing physical metrology operations and tools.

[0029] According to an embodiment of the present invention, the virtual measurement application system provides a data pre-processing mechanism for collecting measurement data sensed by manufacturing equipment in real time and performing pre-processing on the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com