Baking-melting reduction iron smelting method, apparatus and raw amterial

A reduction furnace and reducing agent technology, applied in the field of smelting reduction ironmaking, can solve the problems of increasing the greenhouse gas load of the atmospheric environment, unusable, high-temperature rich air volume and temperature, low volume and temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

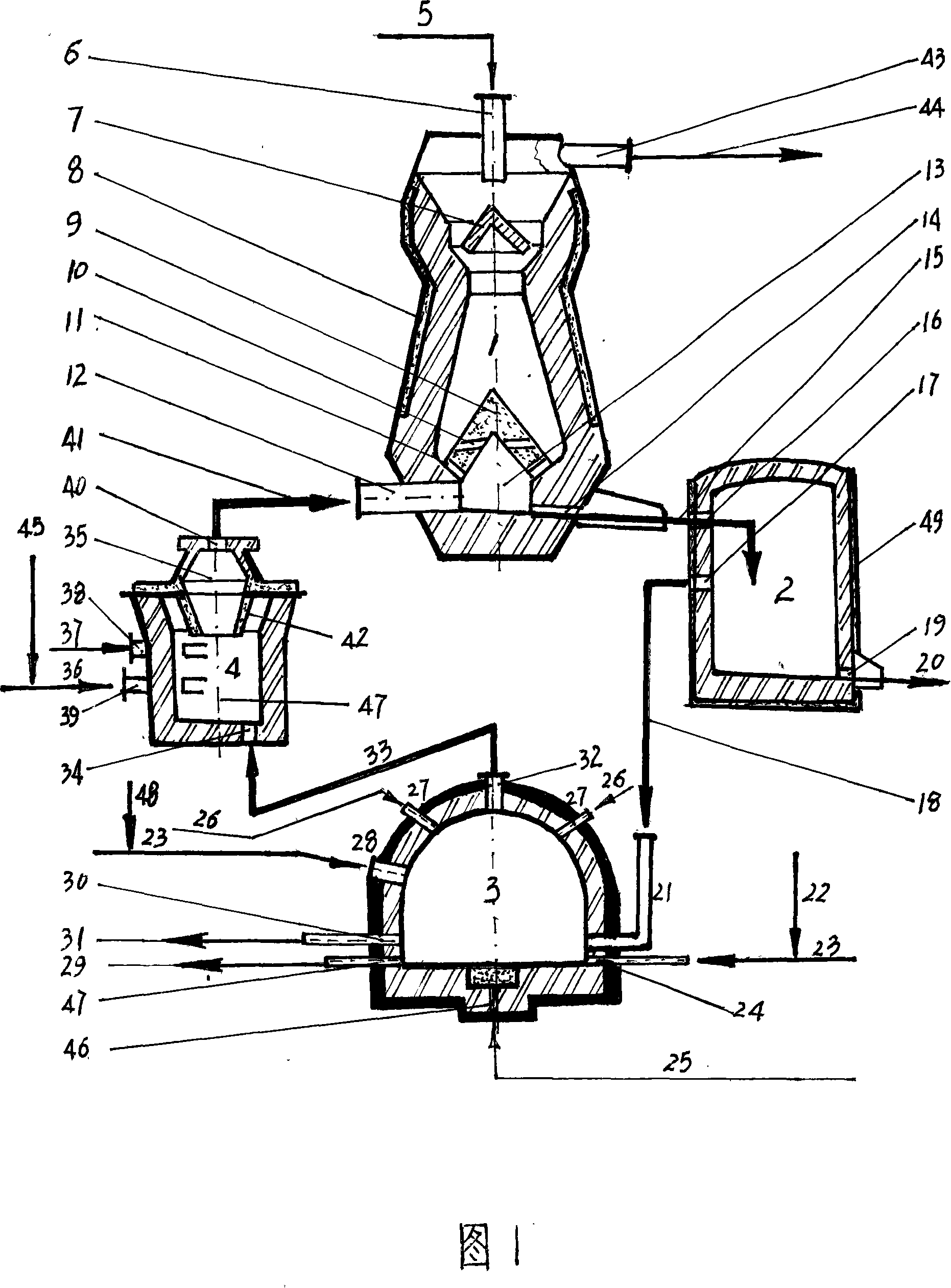

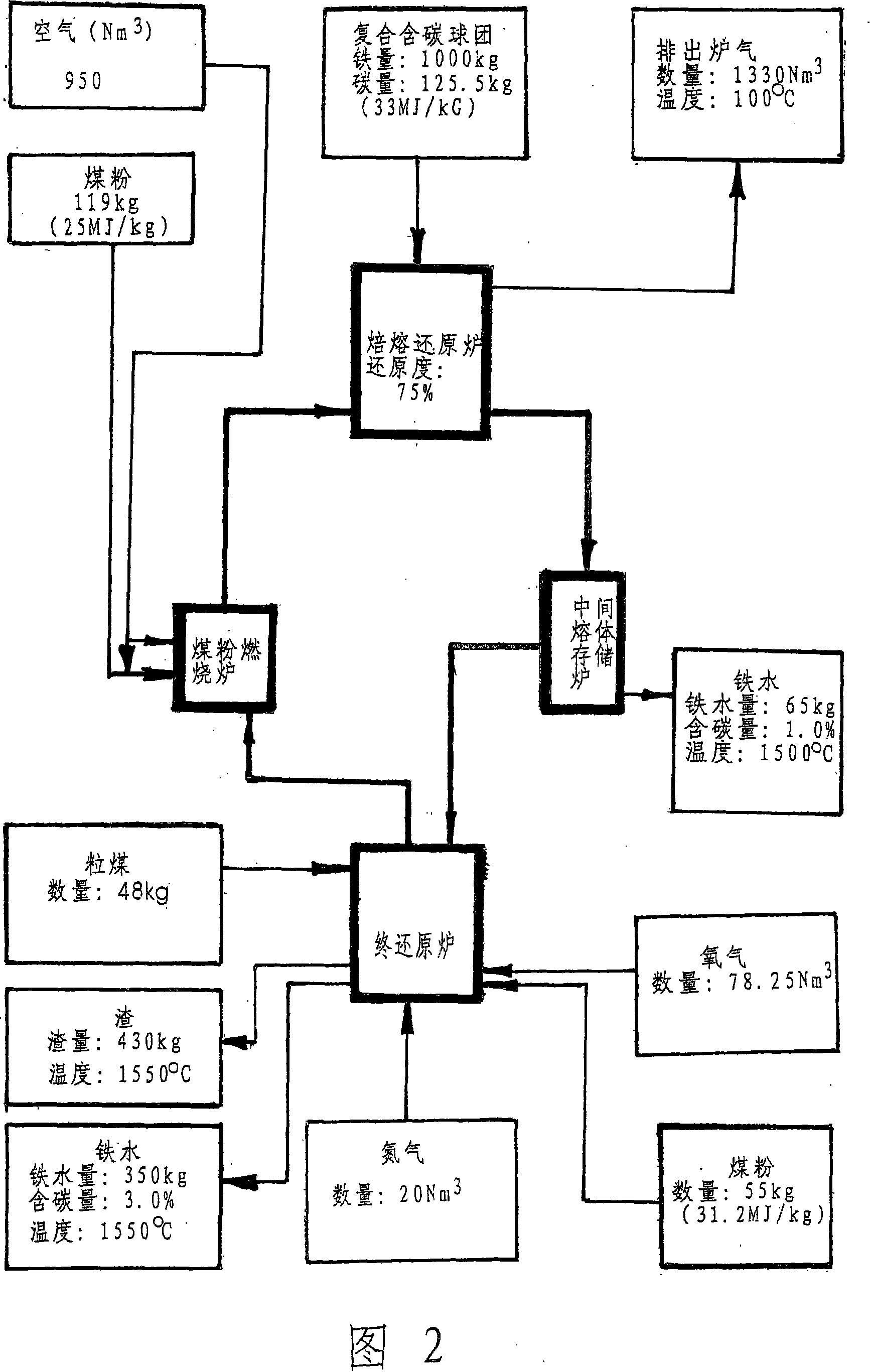

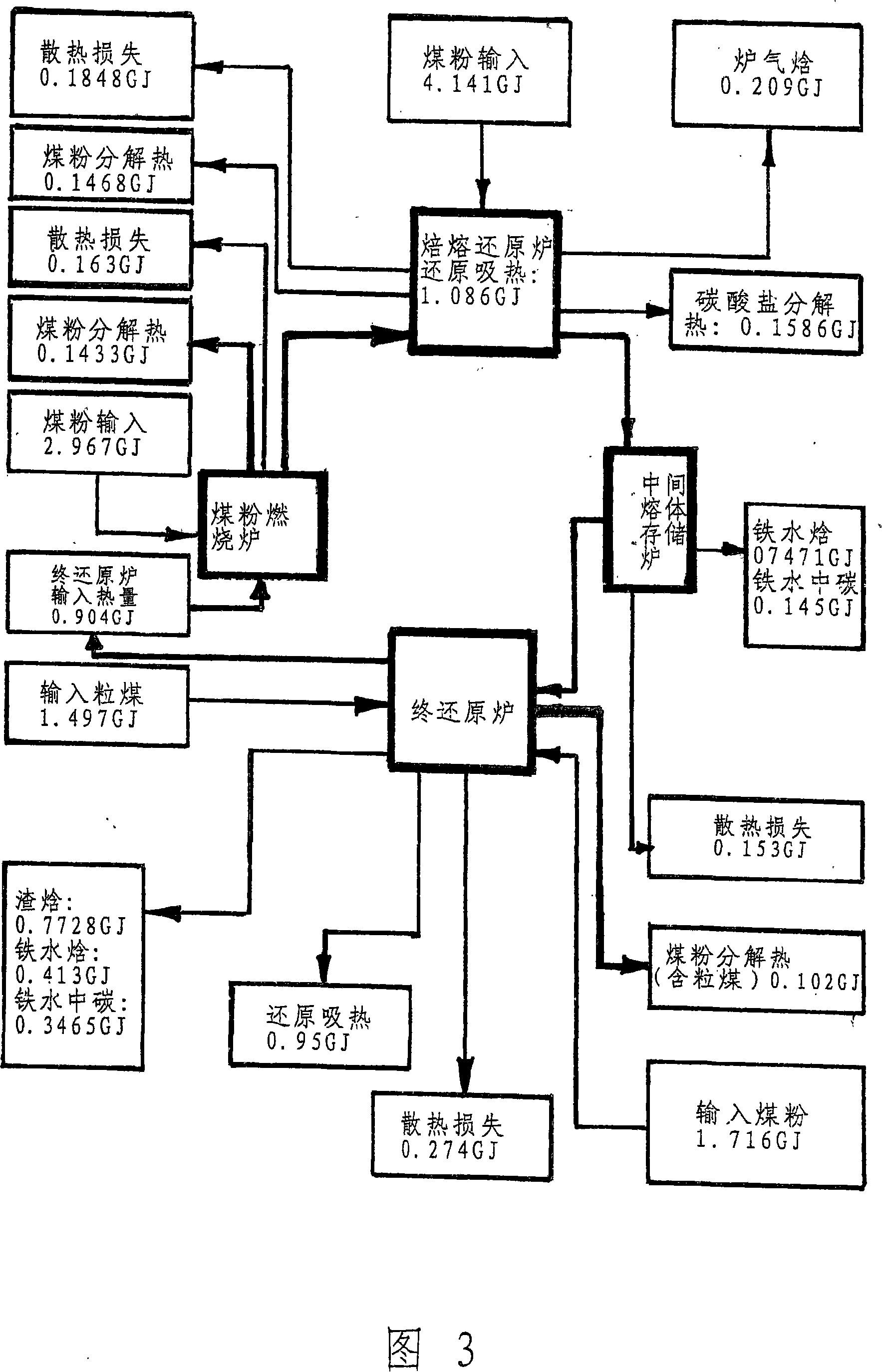

[0120] According to the ironmaking method of composite carbon-containing pellet roasting and smelting reduction circulation system device described in the present invention:

[0121] 1. Preparation of composite carbon-containing pellets

[0122] 1.1 Table 2 The chemical composition % of sulfuric acid slag beneficiation iron concentrate

[0123] TF

FeO

SiO

CaO

Al 2 o 3

MgO

P

S

As

63.58

3.39

6.18

2.25

2.77

1.56

0.035

0.23

0.15

[0124] Table 3 embodiment is mixed into composite pellet-containing anthracite composition%

[0125] fixed carbon

Volatile matter

Ash

S

84.7

3.68

11.37

0.23

[0126] 1.2 Kernel batch:

[0127] [1] Sulfuric acid slag iron concentrate powder (dry material): 786.41kg

[0128] [2] Reduced coal: 140.5kg

[0129] [3] CaO: 21kg

[0130] [4] Binder: 17kg

[013...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com