Method for separating and extracting white Peony Root

A technology of peony and white peony, applied in the field of medicine, can solve the problems of different extraction methods and unsuitable traditional Chinese medicinal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

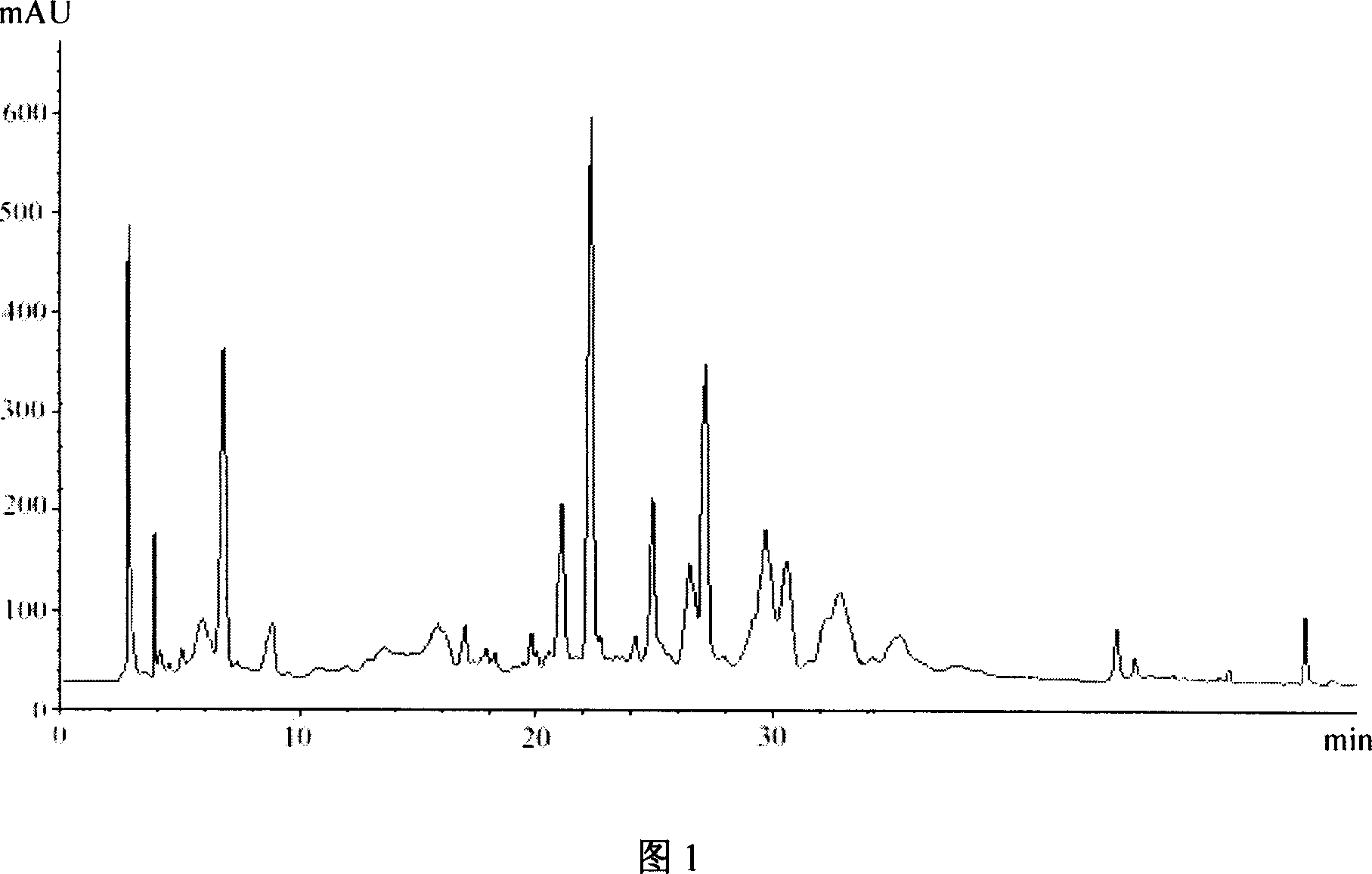

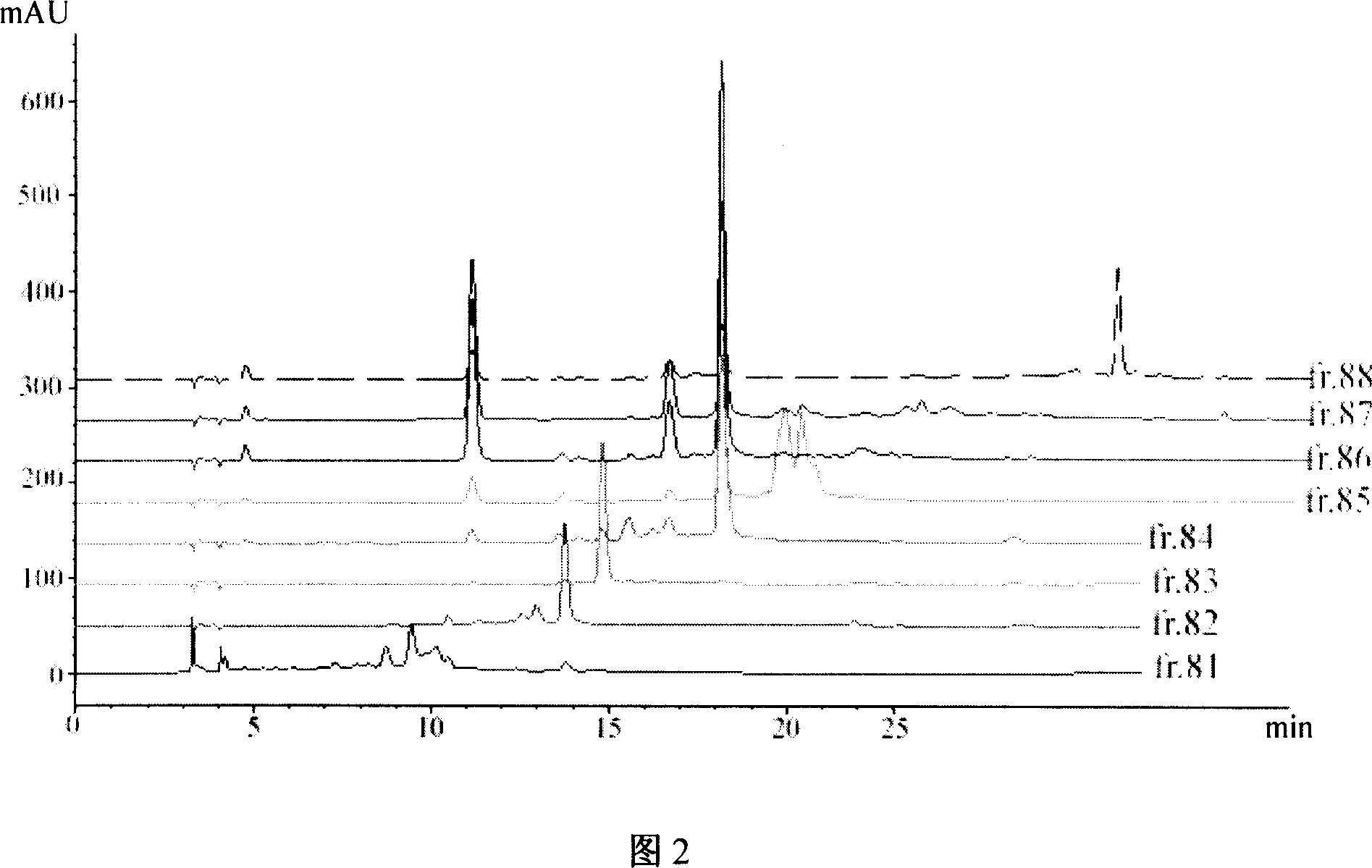

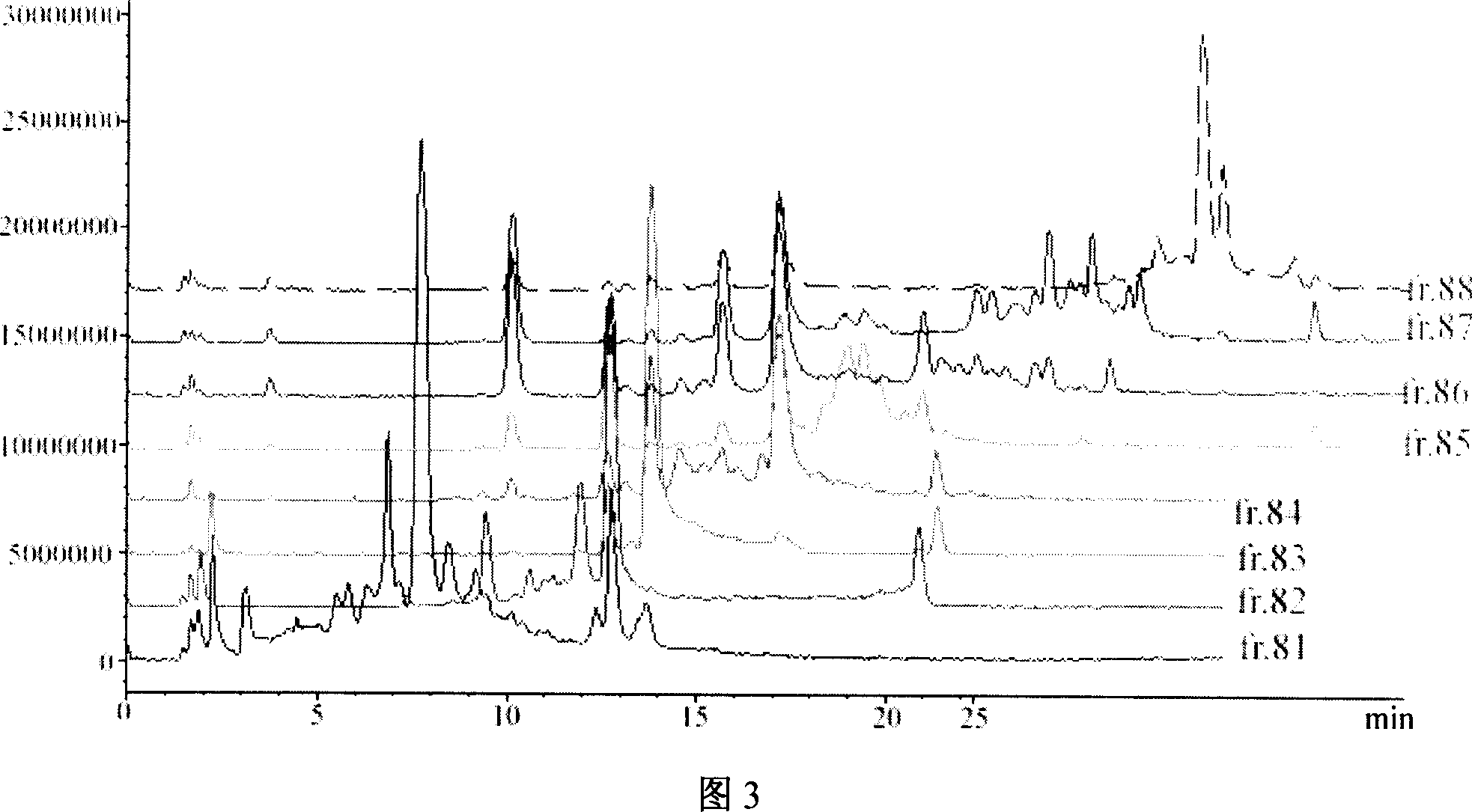

Image

Examples

Embodiment 1

[0067] (1) Extraction process: take 250g of Radix Paeoniae Alba, crush it and sieve it, then add 10 times of ethyl acetate and ethanol with a volume ratio of 7:3, heat and reflux for 3 hours, extract 3 times, and combine the filtrates to obtain Extract fr.1. Add 6 times the amount of 70% ethanol to the dregs, heat and reflux for 2 hours, extract twice, and combine the filtrates to obtain the extract fr.2. Finally add water to the dregs, heat and reflux for 1.5 hours, extract twice, and combine the filtrates to obtain the extract fr.3.

[0068] (2) Separation process: Concentrate the extract fr.1 to obtain 16.8g extract, mix the sample with silica gel, and use a normal phase silica gel column to separate it. First use petroleum ether and ethyl acetate with a volume ratio of 50:1 as Mobile phase, to obtain eluent fr.4, then change the volume ratio of chloroform and methanol as mobile phase to obtain eluent fr.5, concentrate to obtain 1.6g sample, and finally use methanol as mob...

Embodiment 2

[0085] (1) Extraction process: take 500g of Radix Paeoniae Alba, crush it and sieve it, then add 12 times of ethyl acetate and ethanol with a volume ratio of 7:3, heat and reflux for 1 hour, extract 3 times, and combine the filtrates to obtain Extract fr.1. Add 6 times the amount of 70% ethanol to the dregs, heat and reflux for 3 hours, extract once, and combine the filtrates to obtain the extract fr.2. Finally add water to the dregs, heat and reflux for 2 hours, extract twice, and combine the filtrates to obtain the extract fr.3.

[0086] (2) Separation process: Concentrate the extract fr.1 to obtain 21.8g extract, mix the sample with silica gel, and use a normal phase silica gel column to separate it. First, petroleum ether and ethyl acetate with a volume ratio of 50:1 are used as Mobile phase, to obtain eluent fr.4, then replace the chloroform and methanol as mobile phase with a volume ratio of 7:3, obtain eluent fr.5, concentrate to obtain 2.8g sample, finally use methano...

Embodiment 3

[0103] 1. Extraction and separation of Radix Paeoniae Alba

[0104] (1) Extraction process: take 250g of Radix Paeoniae Alba, crush it and sieve it, then add 8 times of ethyl acetate and ethanol with a volume ratio of 7:3, heat and reflux for 1 hour, extract twice, and combine the filtrates to obtain Extract fr.1. Add 8 times the amount of 70% ethanol to the dregs, heat and reflux for 1 hour, extract twice, and combine the filtrates to obtain the extract fr.2. Finally add water to the dregs, heat and reflux for 1 hour, extract twice, and combine the filtrates to obtain the extract fr.3.

[0105] (2) Separation process: Concentrate the extract fr.1 to obtain 16.8g extract, mix the sample with silica gel, and use a normal phase silica gel column to separate it. First use petroleum ether and ethyl acetate with a volume ratio of 50:1 as Mobile phase, to obtain eluent fr.4, then replace the chloroform and methanol as mobile phase with a volume ratio of 7:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com