Clutch body and dabber connector

A technology of clutches and connecting bodies, which is applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve assembly and other problems, achieve the effects of simple production and assembly process, promotion of performance improvement, and improvement of parts performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

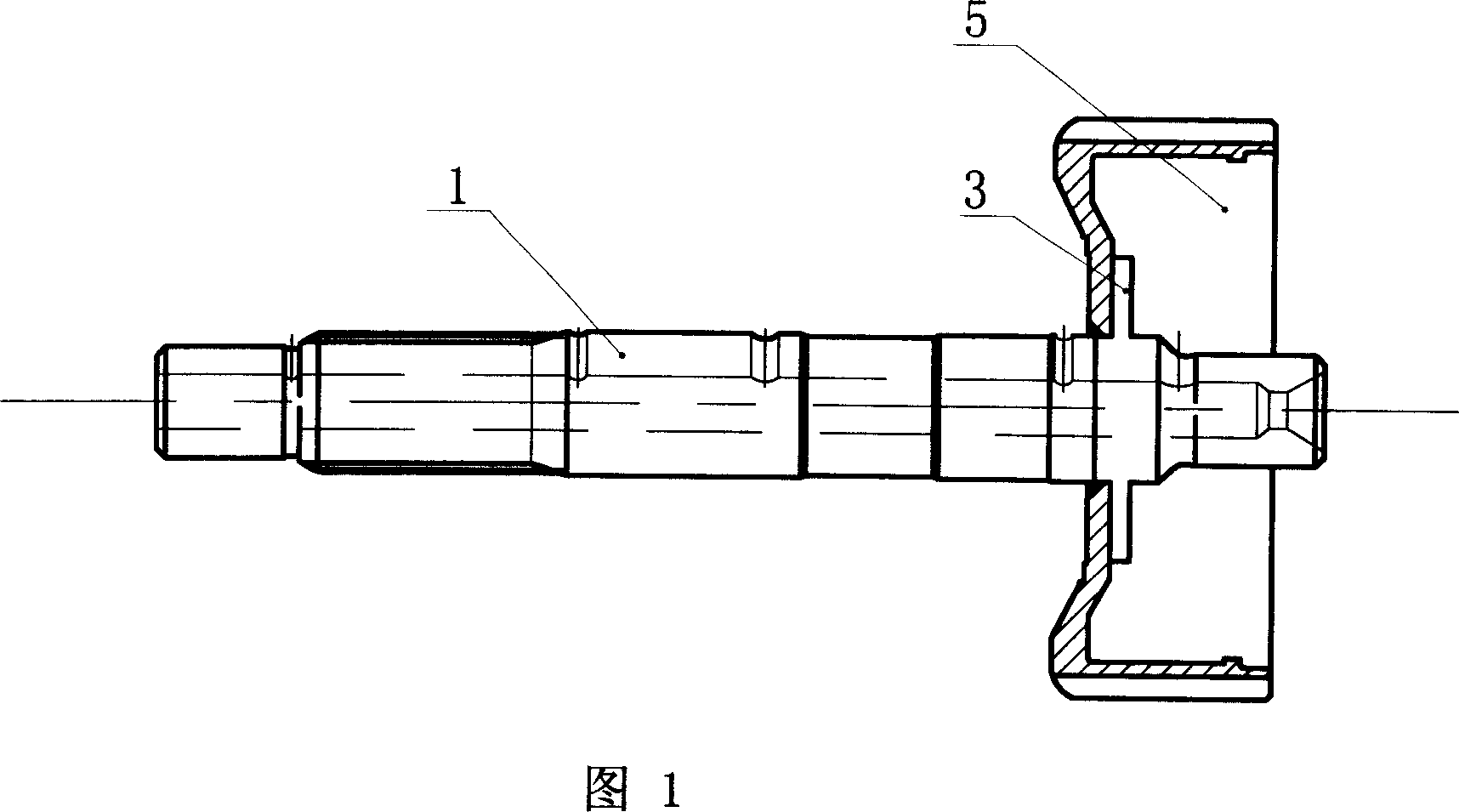

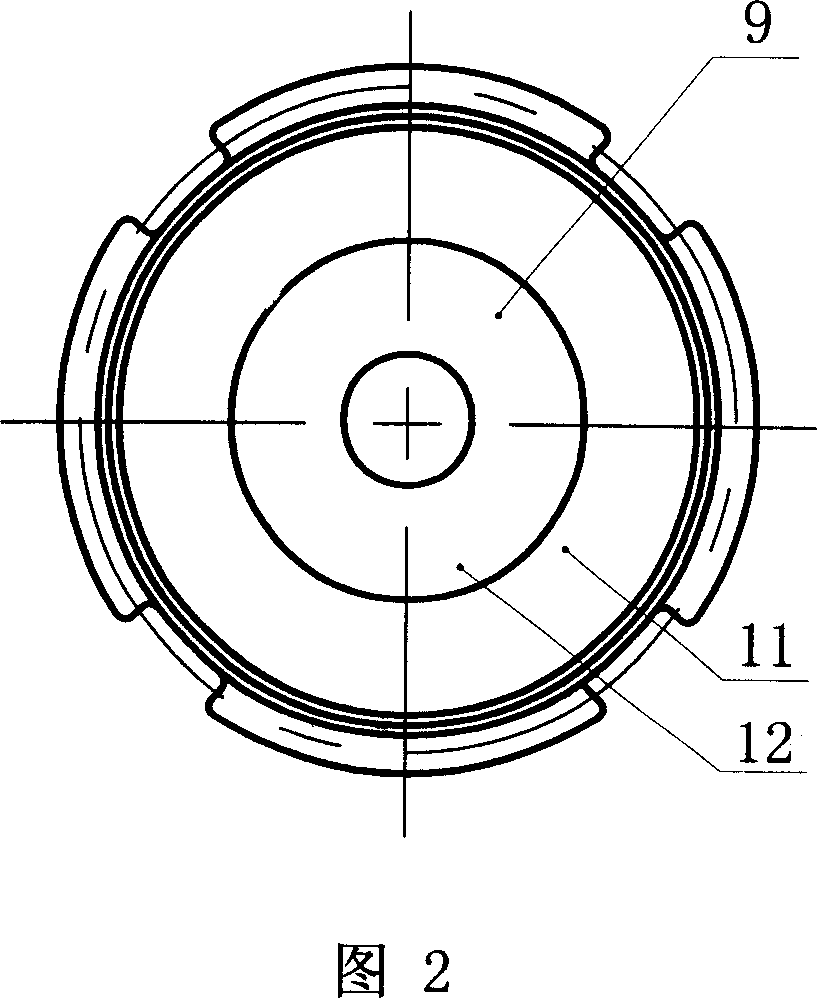

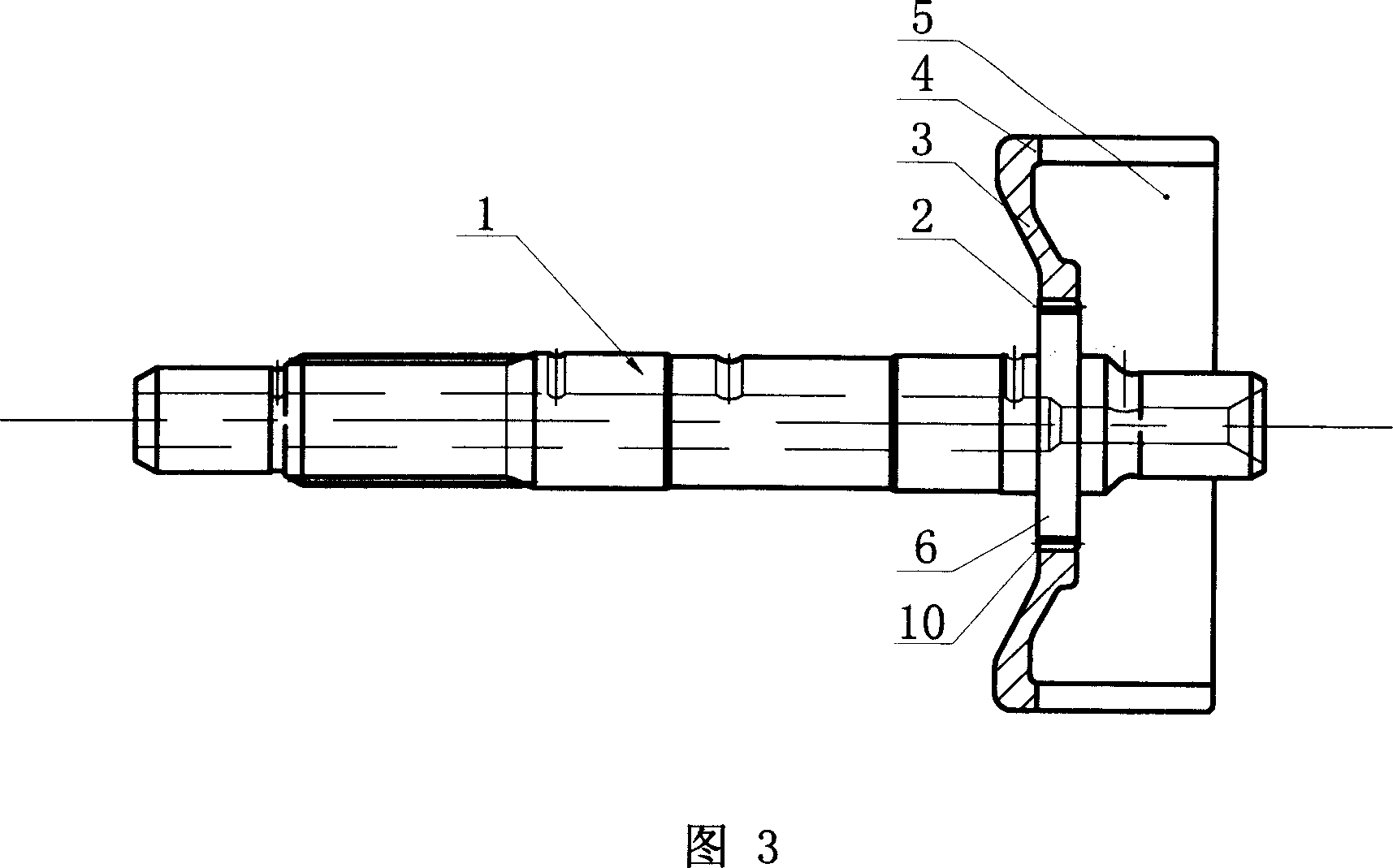

[0019] Embodiment 1: This embodiment is a component used for automobile clutches. Through machining, a section of cylindrical forged steel can be processed into a through-groove clutch body 5, and then a section of forged steel can be processed into a mandrel 1. Here, the most Mainly explain how to assemble the clutch body and the mandrel, because during processing, the diameter of the spline 2 on the mandrel is slightly larger than the diameter of the keyway 10 of the clutch body, this is done to have an interference, so that the mandrel can It is firmly fixed with the clutch body. The spline on the mandrel is to increase the size of the transmission force and is not easy to fail. Compared with the ordinary shaft-hole interference fit, the performance of the spline fit is much improved. The torque of the transmission is also much larger. Here, the temperature difference method is used to cooperate, and the clutch body is heated to about 180 degrees Celsius. At this time, becau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com