Method and apparatus for inspection automatically focusing non-spherical surface

A technology of autofocus and surface detection, which is applied in the direction of measuring devices, optical devices, and testing optical properties, can solve the problems of accuracy and simplicity that cannot meet the requirements of high-precision aspheric surface detection, and achieve great research value and feasibility , high measurement accuracy, simple and reliable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

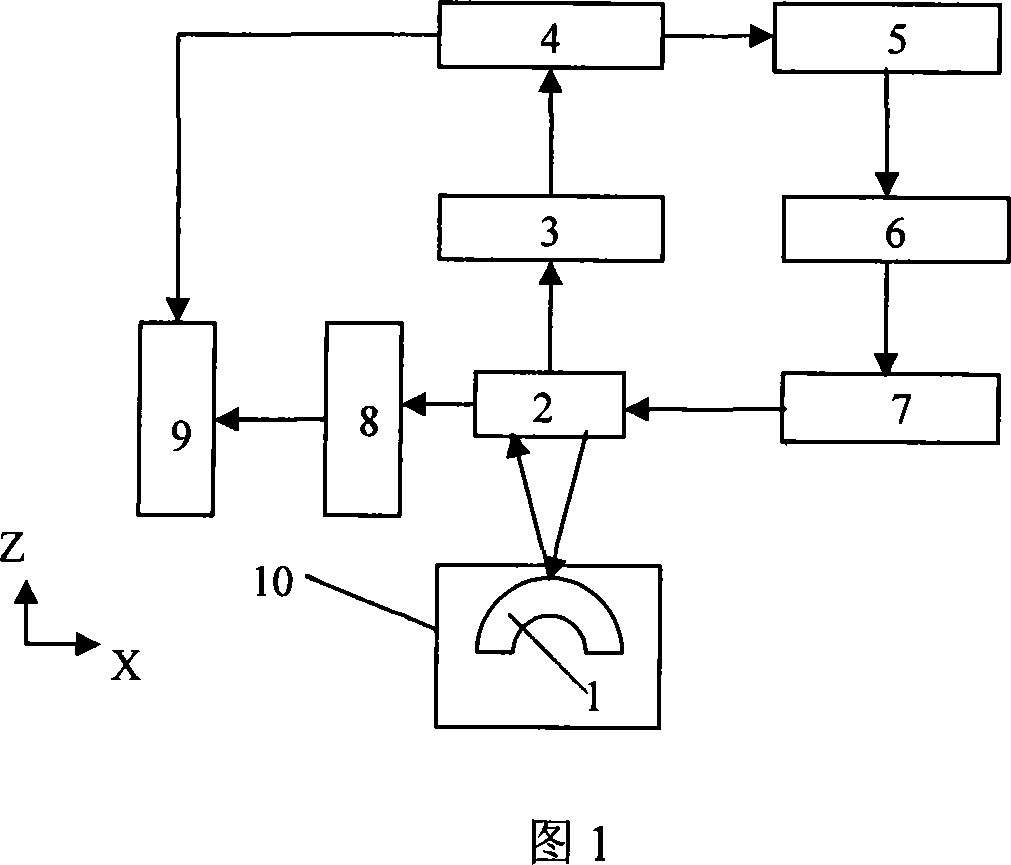

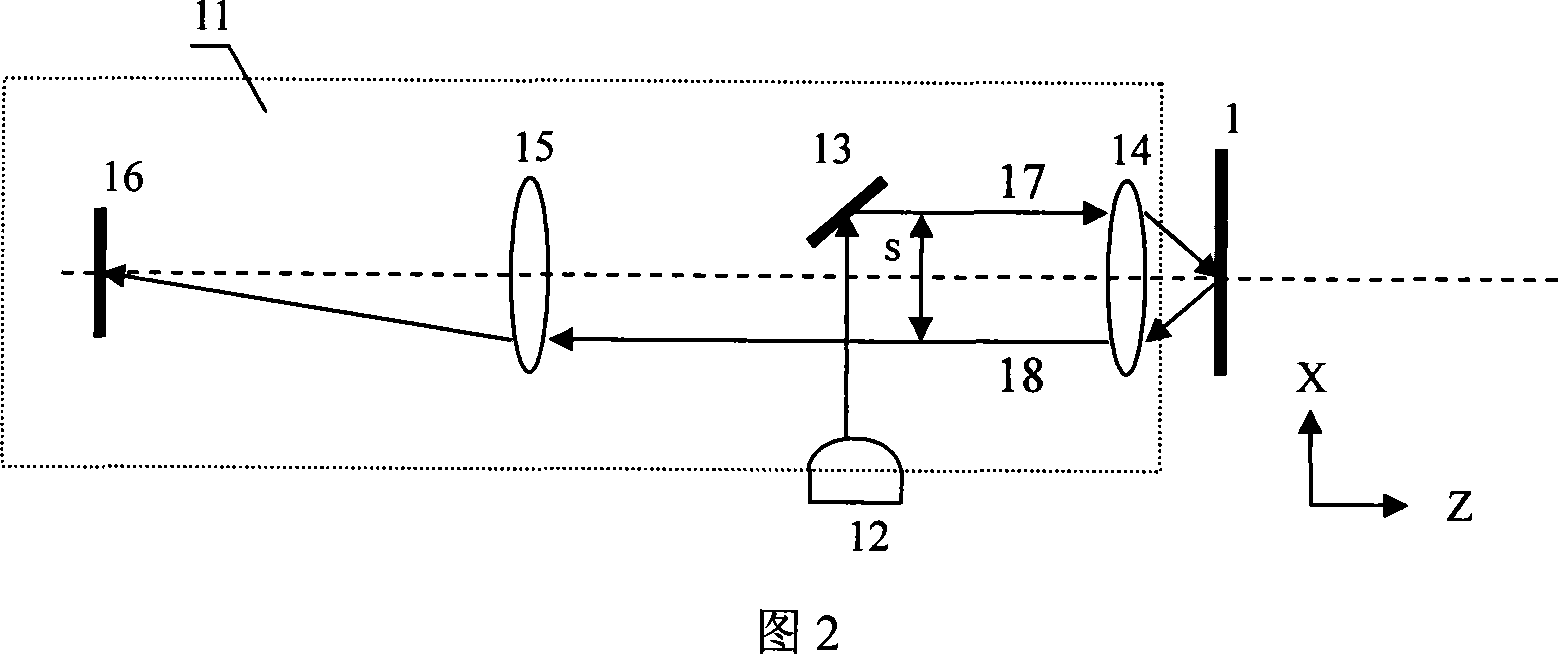

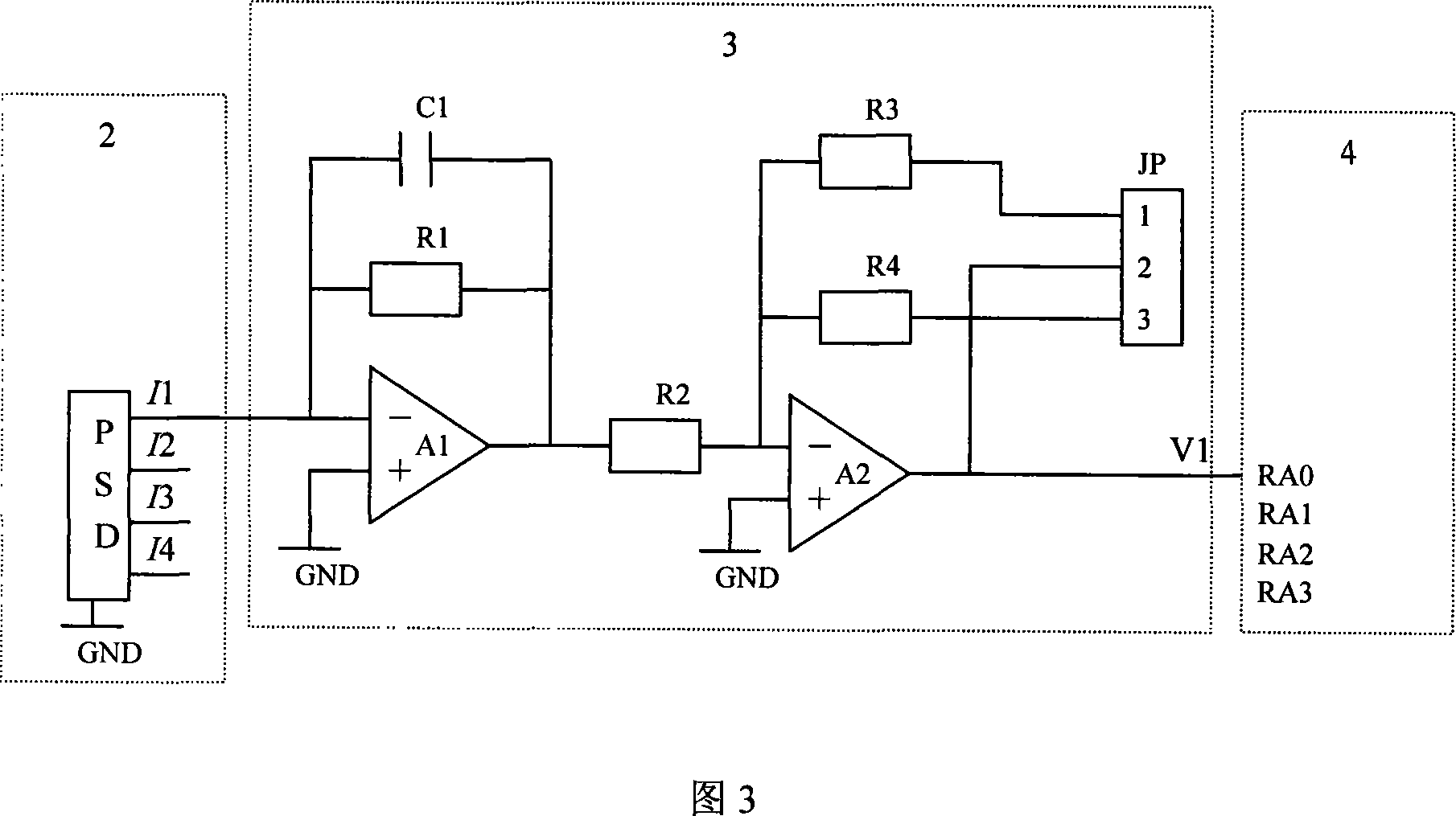

[0028] Referring to Fig. 1 and 2, the aspherical surface detection autofocus device of the embodiment of the present invention is provided with focusing head 2, I / V amplifier 3, single-chip microcomputer 4, optocoupler isolation device 5, servo amplifier 6, servo motor 7, grating ruler 8 and computer9. The focusing head 2 is provided with a barrel 11, a laser 12, a mirror 13, an eyepiece 14, an objective lens 15, and a photodetector 16. The barrel 11 and the grating scale 8 are connected as one, and are connected to the output shaft of the servo motor 7 through a screw. .

[0029] When the aspheric surface measured workpiece 1 on the workpiece table 10 was placed on the focus of the eyepiece 14 of the focus head, the photodetector 16 output current of the focus head processed the analog input I of the single-chip microcomputer 4 by the I / V amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com