Biological dripping and filtering system for purifying organic waste gases and method quick-speed preparing mvcoderm

A technology for biological trickling filtration and organic waste gas, which is applied in chemical instruments and methods, separation methods, and air quality improvement. Application, extensive usability, fast start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

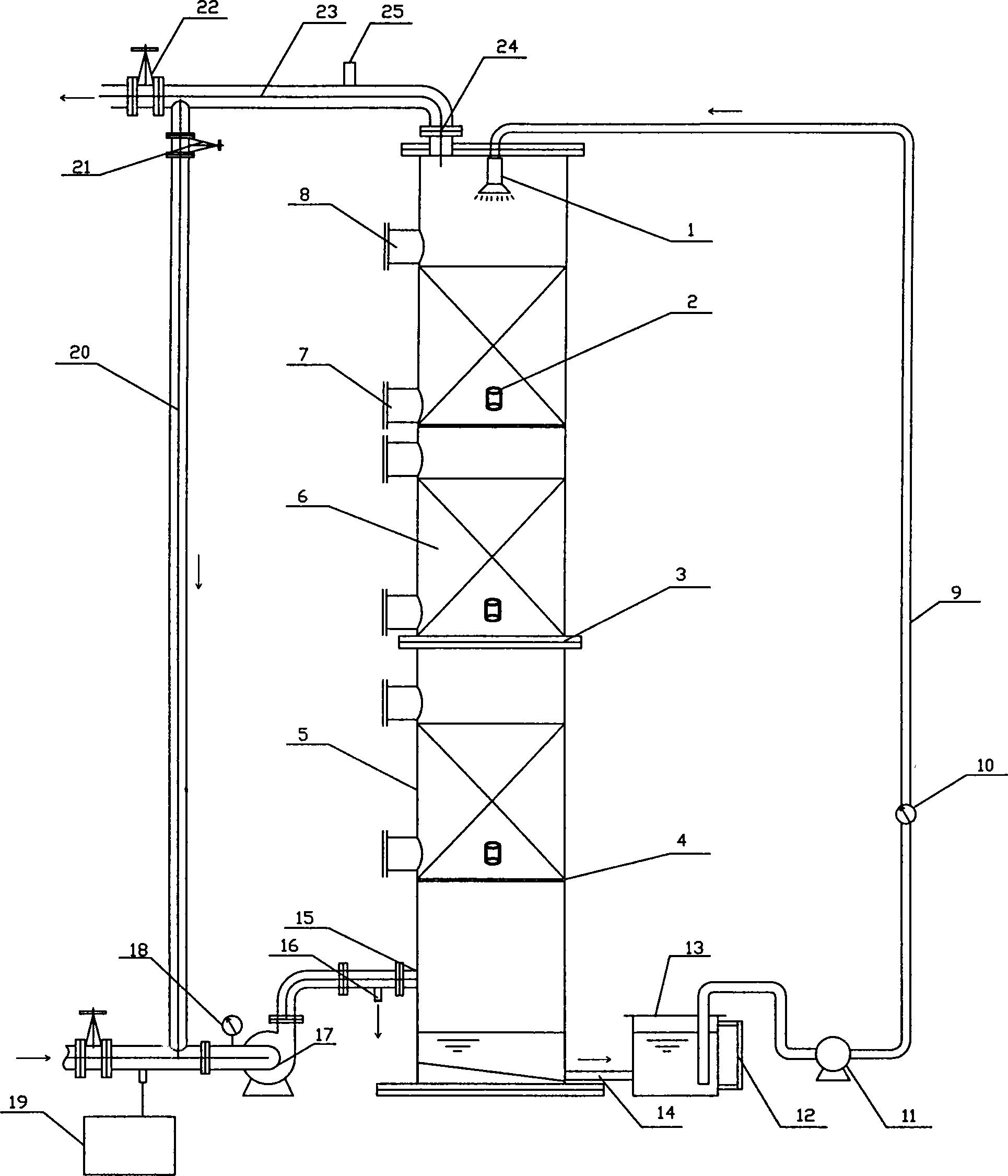

[0021] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0022] The bio-trickling filtration system for purifying organic waste gas of the present invention is composed of a bio-trickling filtration reactor 6 equipped with a filler 2, a barrel seat 5, a liquid circulation device, a waste gas input device and a purified gas circulation device, wherein: the bio-trickling filtration reactor 6 is fixed on the barrel seat 5, and a grid plate 4 is provided between the bio-trickling filter reactor 6 and the barrel seat 5. The middle part of the barrel seat 5 is connected to the exhaust gas input device through the gas inlet 15, and the bottom is connected to the liquid circulation device through the connecting pipe 14 , the top cover of the bio-trickling filter reactor 6 is provided with a spray head 1 connected to the liquid circulation device, and is provided with a gas outlet 24, and the gas outlet 24 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com