CG150 engine applying lightweight optimization and dynamic balance optimization technique

An engine and technology technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of serious vibration and small torque output of the whole machine, and achieve the effect of reducing the vibration of the whole machine and increasing the torque output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

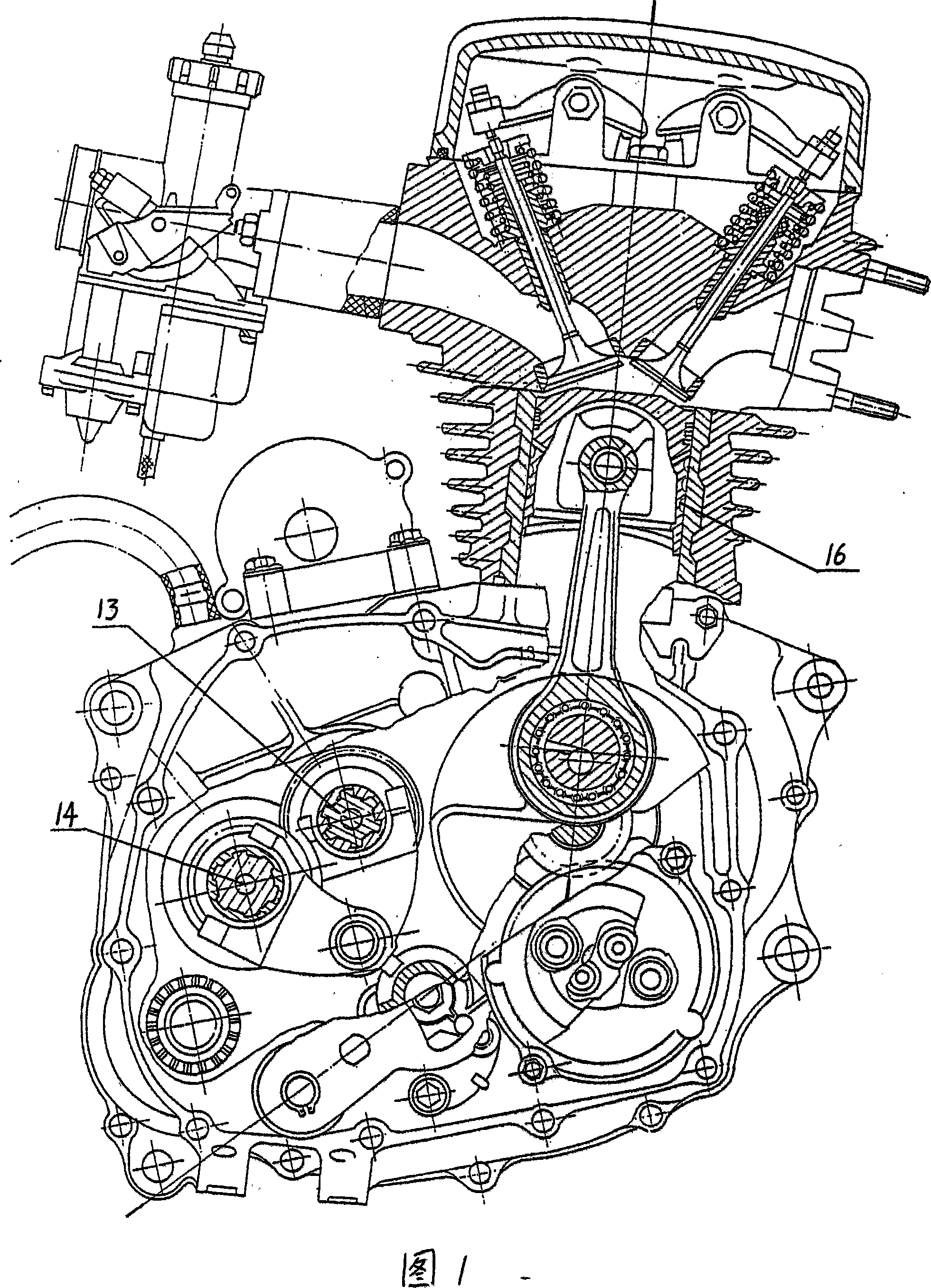

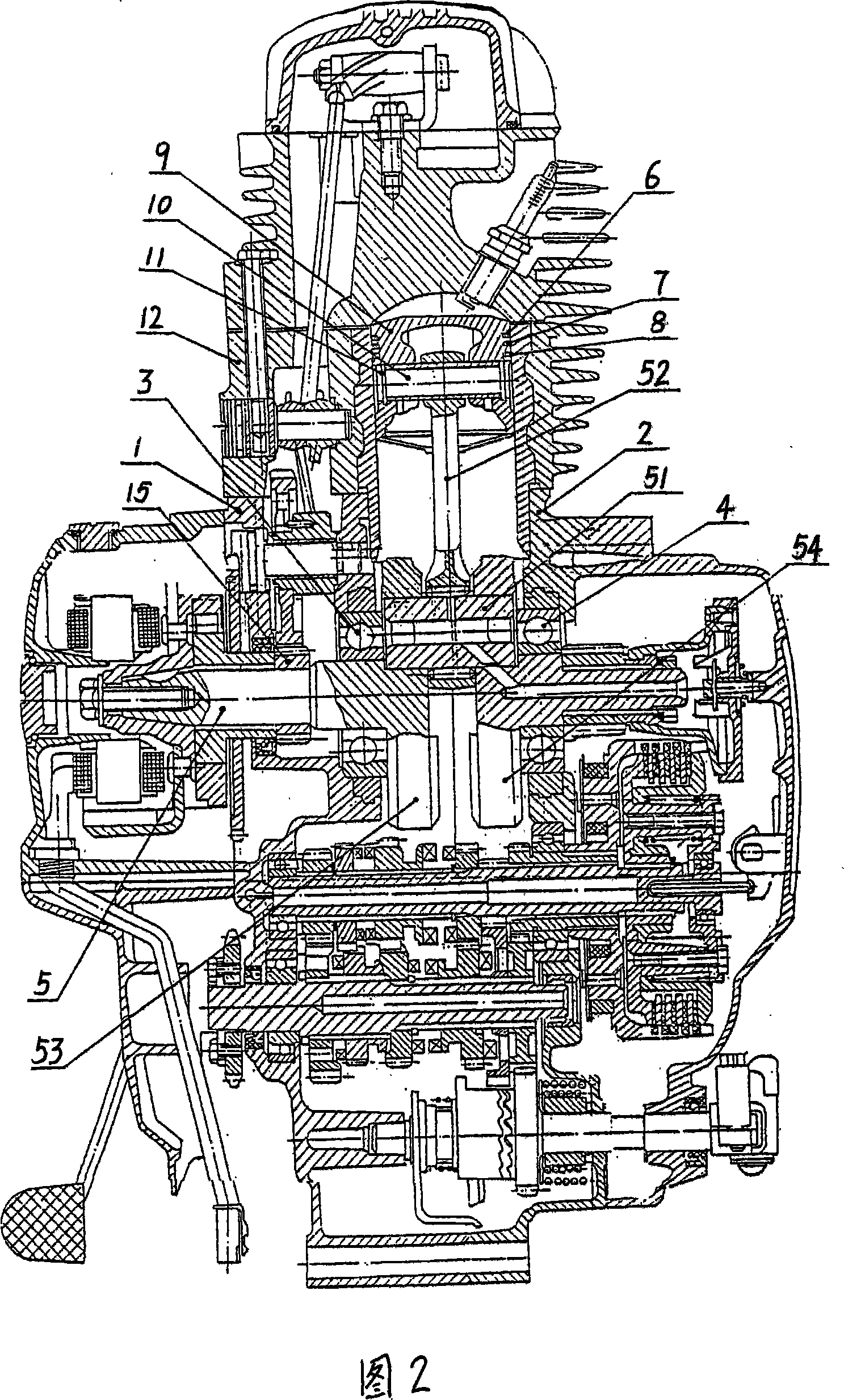

[0015] As shown in Figure 1 and 2.

[0016] The light-weight optimization and dynamic balance optimization technology of the present invention designs a CG150 engine for a motorcycle, including a piston ring 6, a piston ring 7, an oil ring 8, a piston 9, a piston pin 10, a crank connecting rod assembly 5, and a piston pin gear clip 11 , cylinder 12, left box body 1 and right box body 2 etc. parts. Its working principle is the same as internal combustion engine technology.

[0017] Its improved structure involves the following parts: the first piston ring 6 and the second piston ring 7 are reduced by 1 / 3 compared with normal; the thickness of oil ring is reduced by 2 / 5 compared with normal; the total height of piston is reduced by 1 / 3 compared with normal piston , the skirt is also opened to increase three oil storage tanks 16; the length of the piston pin 10 matched with the piston is reduced by 4.4mm compared with the normal, and the outer diameter of the piston pin is reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com