Transmission system of double-bridge liquid-driving mixed power automobile

A hybrid vehicle and transmission system technology, applied in the transmission system field of hydrostatic drive hybrid vehicle, can solve the problems of low transmission efficiency, energy recovery rate and recycling rate, improve fuel economy, ensure adaptability, The effect of improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

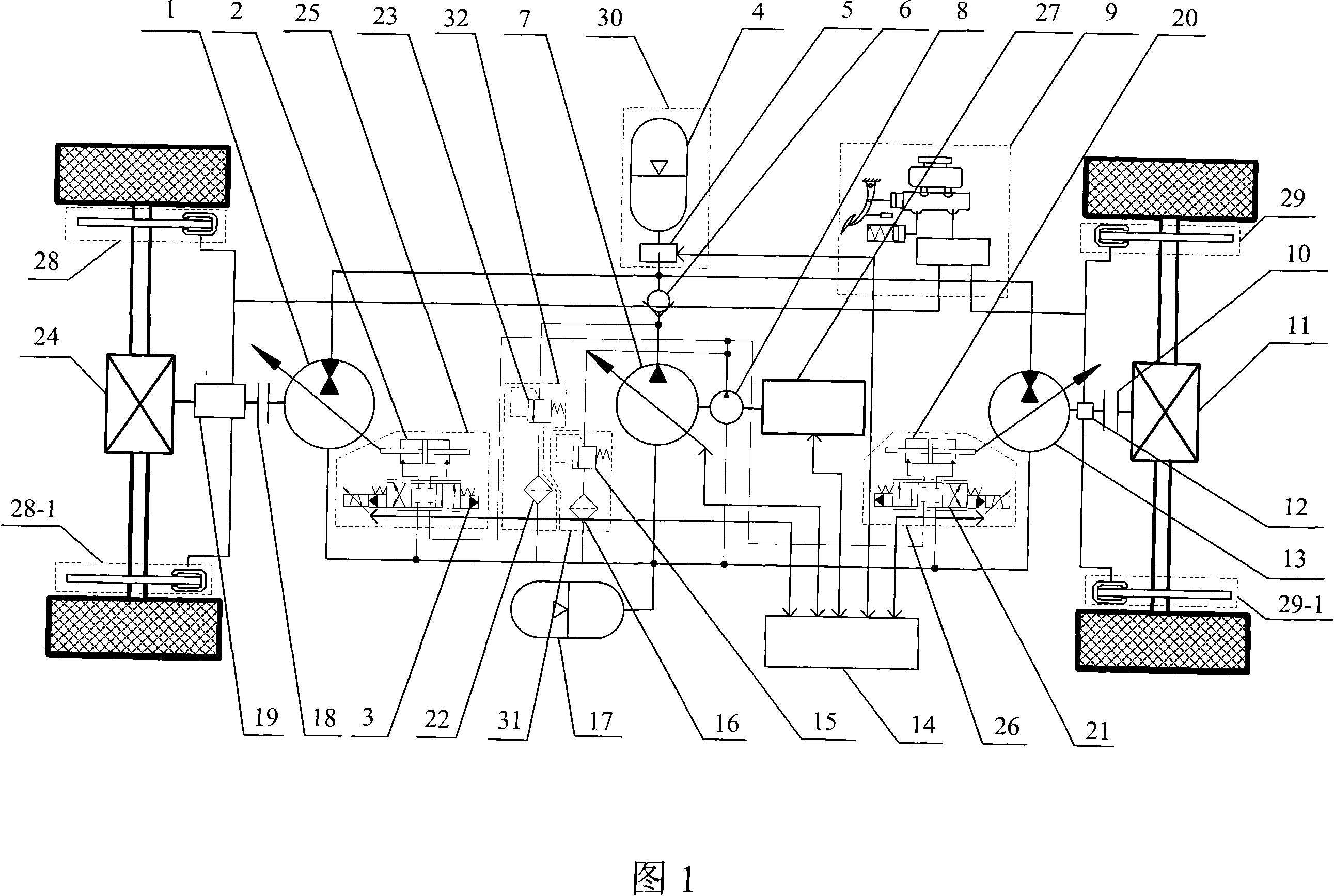

[0011] Specific embodiment 1: Referring to Fig. 1, this embodiment consists of a front axle hydraulic pump / motor 1, a one-way valve 6, a constant pressure variable pump 7, a quantitative pump 8, a mechanical friction brake controller 9, and a rear axle wet multi-plate clutch 10. Torque speed sensor 12, rear axle hydraulic pump / motor 13, central controller 14, low pressure hydraulic accumulator 17, front axle wet multi-plate clutch 18, transmission 19, front axle hydraulic pump / motor control assembly 25, rear Axle hydraulic pump / motor control assembly 26, high-pressure hydraulic energy storage assembly 30, first overflow assembly 31 and second overflow assembly 32, oil inlet port of front axle hydraulic pump / motor 1, rear axle hydraulic pump / motor The oil inlet port of 13 and the oil outlet port of the check valve 6 communicate with the oil port of the high-pressure hydraulic energy storage assembly 30, the oil inlet port of the first overflow assembly 31, the oil inlet port of ...

specific Embodiment approach 2

[0013] Specific embodiment two: referring to Fig. 1, the front axle hydraulic pump / motor control assembly 25 of the present embodiment is made up of the first electro-hydraulic servo valve 3 and the first variable oil cylinder 2, the P port of the first electro-hydraulic servo valve 3 is connected with the quantitative The oil outlet port of the pump 8 is connected, the O port of the first electro-hydraulic servo valve 3 is connected with the oil port of the low-pressure hydraulic accumulator 17, and the A and B ports of the first electro-hydraulic servo valve 3 are connected with the ports of the first variable cylinder 2 respectively. The oil inlet and outlet ports are connected, and the piston rod of the first variable oil cylinder 2 is mechanically connected with the swash plate of the front axle hydraulic pump / motor 1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014]Specific embodiment three: Referring to Fig. 1, the rear axle hydraulic pump / motor control assembly 26 of this embodiment is composed of a second electro-hydraulic servo valve 21 and a second variable cylinder 20, the P port of the second electro-hydraulic servo valve 21 is connected to the quantitative The oil outlet port of the pump 8 is connected, the O port of the second electro-hydraulic servo valve 21 is connected with the oil port of the low-pressure hydraulic accumulator 17, and the A and B ports of the second electro-hydraulic servo valve 21 are connected with the second variable oil cylinder 20 respectively. The oil inlet and outlet ports are connected, and the piston rod of the second variable oil cylinder 20 is mechanically connected with the swash plate of the rear axle hydraulic pump / motor 13. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com