Humic acid in peat particle and preparation method thereof

A peat humic acid and humic acid technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of slow effect, slow process, single nutrient, etc., to increase soil organic matter, low cost, and mediate soil The effect of acid-base environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

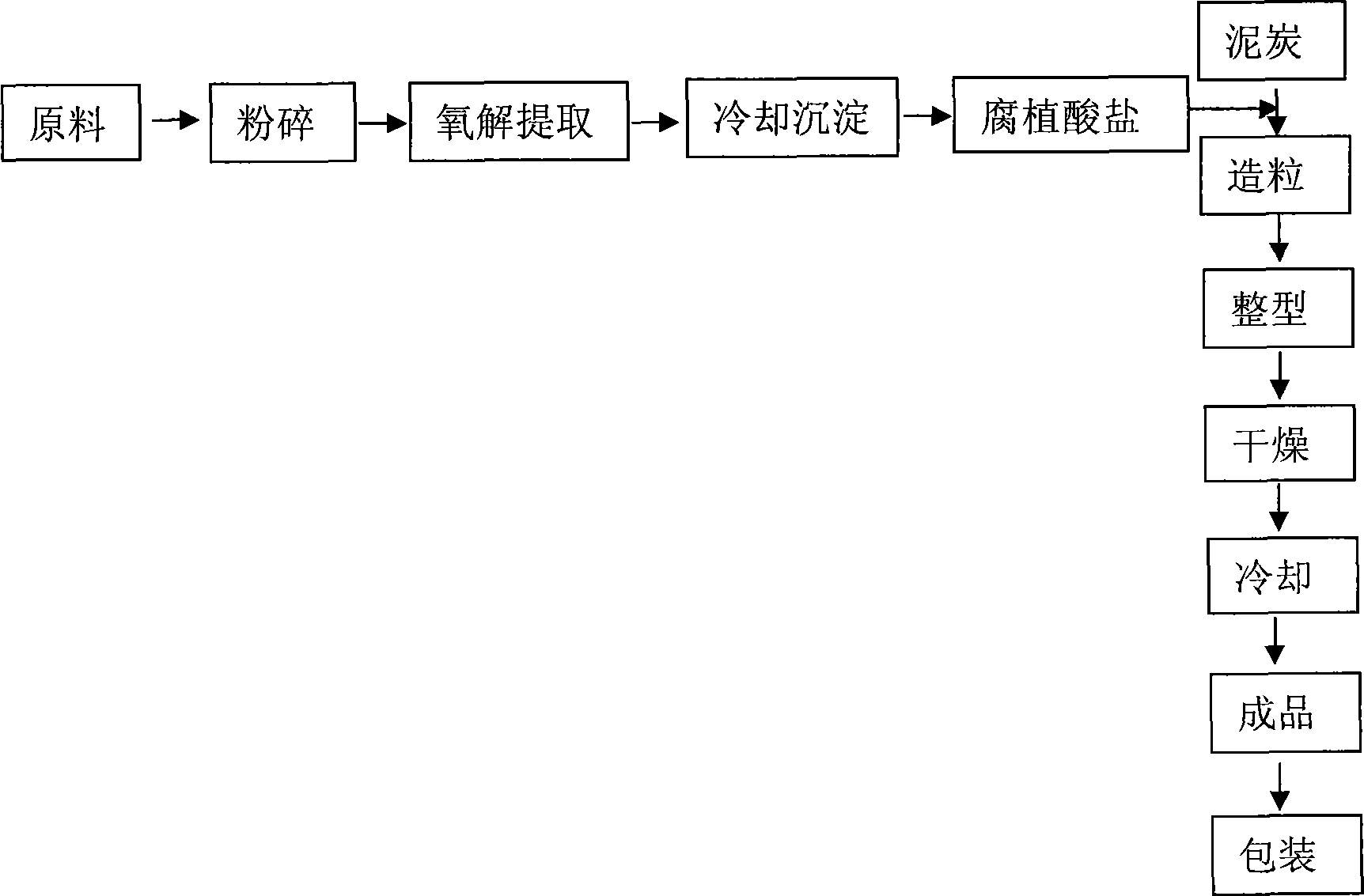

Method used

Image

Examples

Embodiment 1

[0022] Select peat with a decomposition degree of 20% and a humic acid content of 20%, air-dry naturally to a water content of 35%, then crush it to 2mm with a pulverizer, weigh 1kg of peat on the upper part of the sieve, add 1250ml of 20% ammonia solution, and stir evenly. Heat to boiling and react for 10min. After static precipitation for one day, the supernatant was extracted by siphon method, diluted to 1 / 10000, and neutralized with 0.5% sulfuric acid to pH 6, which was liquid humate. Select herbal peat with a decomposition degree of 25% and an ash content of 30%, air-dry it naturally, control its moisture content at 55%, and send it into the mixer at a weight ratio of 1:0.05, while adding the above-mentioned humate , while stirring, sent to the granulator, granulated by the flying knife method for 3 minutes, polished and shaped, sent to the dryer, dried at 70°C for 25 minutes, cooled after coming out, and then packed into bags.

Embodiment 2

[0024] Select the lignite with humic acid content of 30%, naturally air-dry to 20% water content, then pulverize to 2mm with a pulverizer, weigh 1kg of lignite on the top of the sieve, add 1500ml of 1% sodium hydroxide solution, stir evenly, and heat to boiling. React for 10 minutes. After static precipitation for one day, the supernatant was extracted by siphon method, diluted to 5 / 10000, and neutralized with 0.5% sulfuric acid to pH 7, which was liquid humate. Select herbal peat with a decomposition degree of 25% and an ash content of 20%, air-dry it naturally, control its moisture content at 65%, and send it into the mixer at a weight ratio of 1:0.08, while adding the above-mentioned humate , while stirring, sent to the granulator, granulated by the flying knife method for 4 minutes, polished and shaped, sent to the dryer, dried at 100°C for 30 minutes, cooled after coming out, and then packed into bags.

Embodiment 3

[0026] Select weathered coal with a humic acid content of 40%, air-dry naturally to a water content of 20%, then crush it to 2 mm with a pulverizer, weigh 1 kg of weathered coal on the upper part of the sieve, add 1000 ml of 2% potassium hydroxide solution, stir evenly, and heat to Boiling, reaction 15min. After static precipitation for one day, the supernatant was extracted by siphon method, diluted to 3 / 10000, and neutralized with 0.5% sulfuric acid to pH 8, which was liquid humate. Select herbal peat with a decomposition degree of 25% and an ash content of 25%, air-dry it naturally, control its water content at 60%, and send it into the mixer at a weight ratio of 1:0.1, while adding the above-mentioned humate , while stirring, sent to the granulator, granulated by the flying knife method for 4 minutes, polished and shaped, sent to the dryer, dried at 150°C for 25 minutes, cooled after coming out, and then packed into bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com