An airflow guiding slot plate of fuel battery

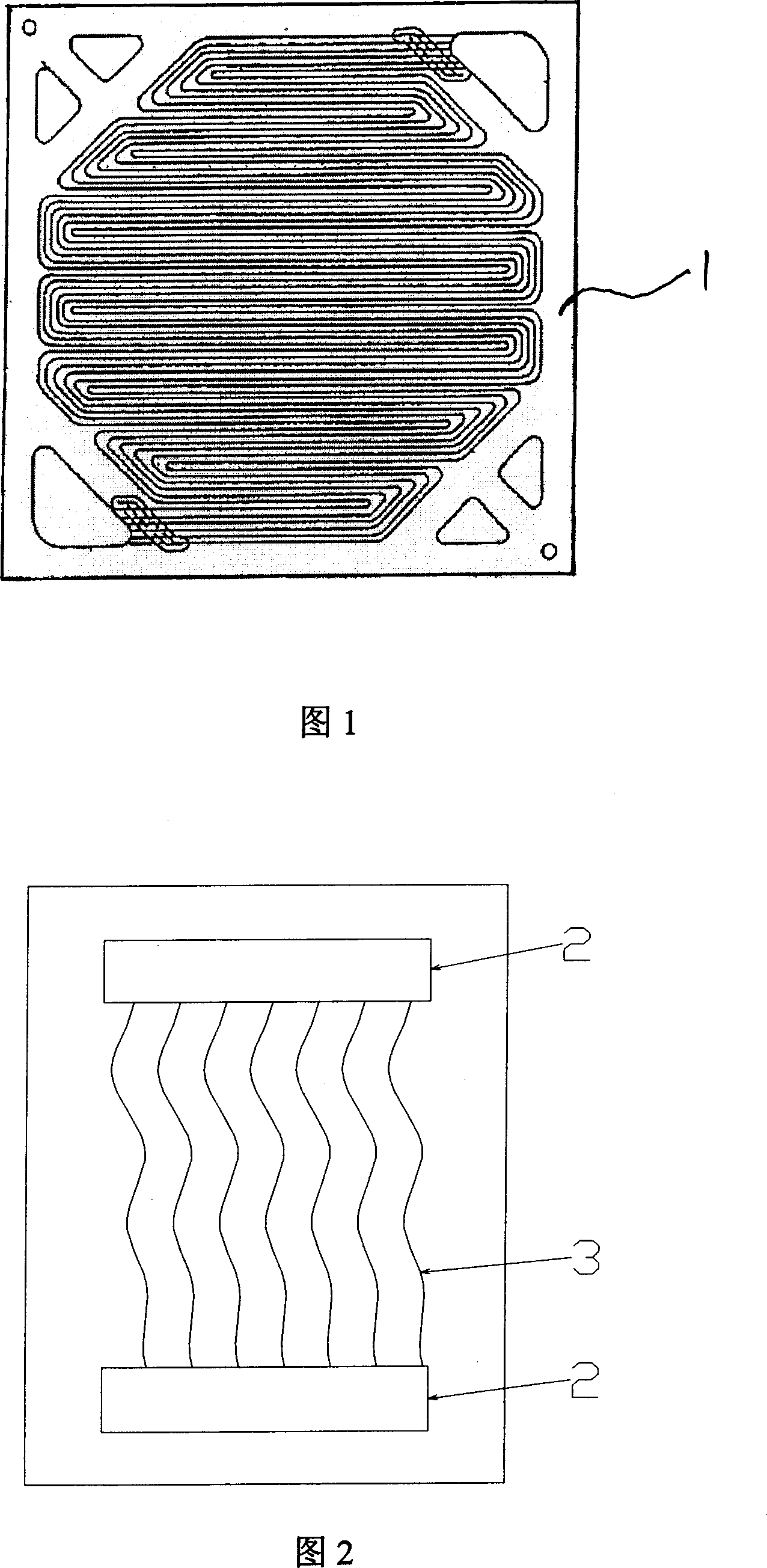

A technology of fuel cells and air flow channels, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of difficult layout and large effective area of plates, and achieve increased active area, increased power density, The effect of small pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

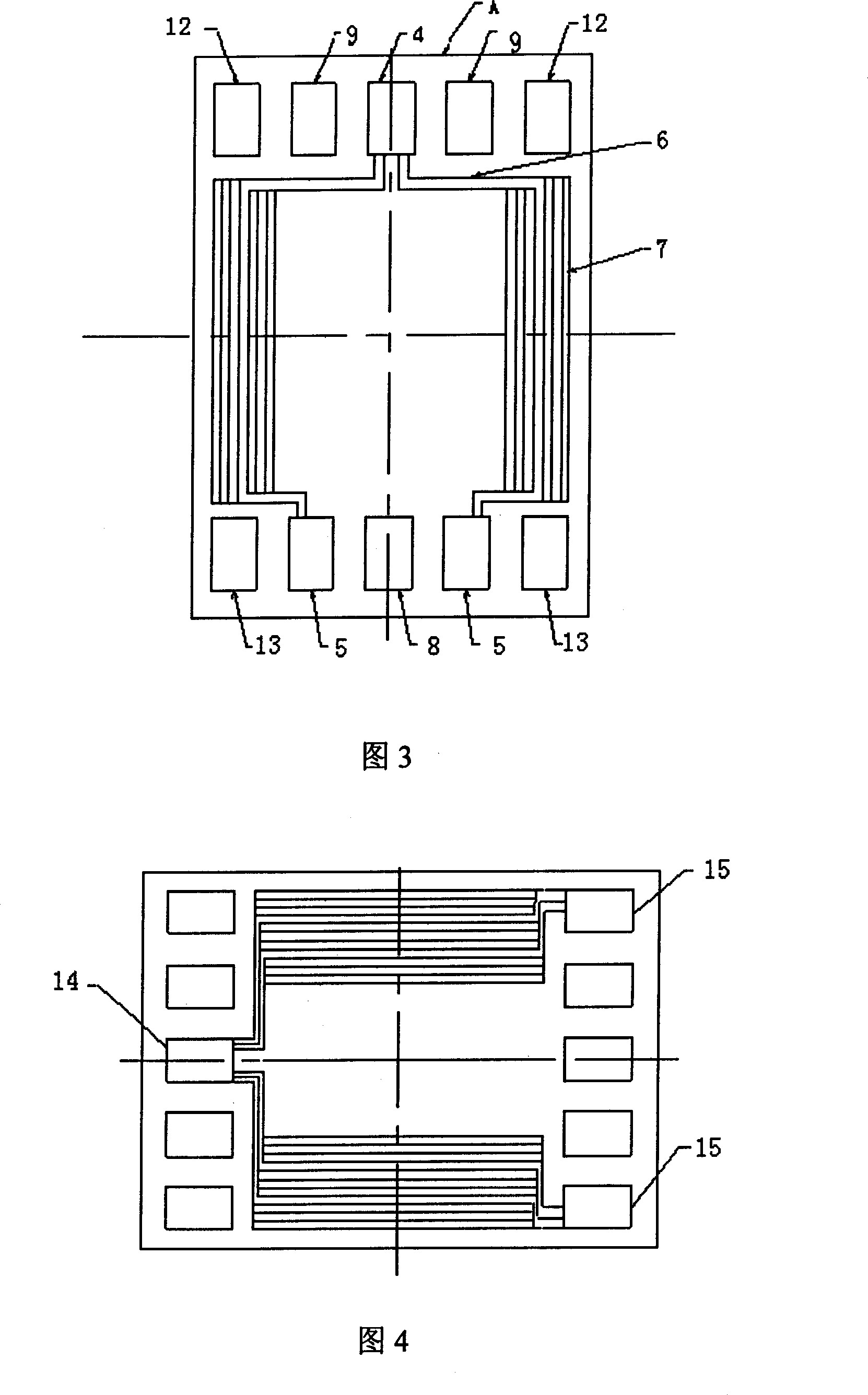

[0041] As shown in Fig. 3, a kind of guide air channel plate of fuel cell, described air guide channel plate is made up of positive air guide channel plate A, back guide cooling fluid channel, described air guide channel plate There are single-hole 4-inlet and double-hole 5-outlet fluid holes. The air-inlet fluid hole is divided into four air-guiding flow grooves 6, and each of the four air-guiding flow grooves is divided into four branch air-guiding flow grooves in a parallel straight-line shape. 7. The branch air flow grooves 7 are collected into the four air flow grooves at the other end, and the four air flow grooves respectively enter the fluid holes 5 of the air; the air flow groove plate is provided with a single hole 8 inlets, double holes and 9 hydrogen outlet fluid holes; the guide air flow slot plate is provided with double holes inlet 12, double holes outlet 13 fluid holes for cooling fluid, and the fluid holes entering the cooling fluid are divided into four guide ...

Embodiment 2

[0044] As shown in Figure 4, a kind of air-guiding flow channel plate of a fuel cell, the air-guiding air flow channel plate is a flow-guiding unipolar plate, and the described air-guiding flow channel plate is provided with a single hole 14 for air inlet and a double hole 15 for air outlet The fluid hole of the air inlet is divided into six air-guiding flow grooves, and each of the six air-guiding flow grooves is divided into four branch air flow grooves in a parallel straight-line shape, and the branch air flow grooves are brought together to the other end. Six air-guiding flow grooves, and the six air-guiding flow grooves respectively enter the fluid holes for air outlet; the air-guiding flow groove plate is provided with fluid holes for single-hole inlet and double-hole hydrogen outlet; the air-guiding flow grooves The slot plate is provided with double holes for inlet and outlet for cooling fluid; the opposite side of the guide air flow slot plate is a flat plate.

[0045...

Embodiment 3

[0047] Please refer to Fig. 3, a fuel cell guide air channel plate, the guide air channel plate is a guide unipolar plate, the air guide channel plate is provided with a single hole into, four holes out of the air Fluid hole, the fluid hole for air inlet divides twenty air-guiding flow grooves, and each of the twenty air-guiding flow grooves divides into two branch air flow grooves in a parallel straight-line shape, and the branch air flow grooves gather together again. To the twenty air-guiding flow channels at the other end, the twenty air-guiding flow channels respectively enter the fluid holes for air outlet; holes; the air-guiding trough plate is provided with three holes for entering and four holes for cooling fluid out; the reverse side of the air-guiding trough plate is a flat plate.

[0048] The guide holes of the above-mentioned air-guiding chute plate are respectively concentrated at the upper and lower ends of the air-guiding chute plate, and the fluid single holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com