Solar energy photocatalytic reactor based on condenser of composite paraboloid

A photocatalytic reactor and compound paraboloid technology, applied in the fields of photocatalytic reaction and solar photocatalytic reactor, can solve the problems of difficult cleaning of the catalytic bed and achieve the effect of high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

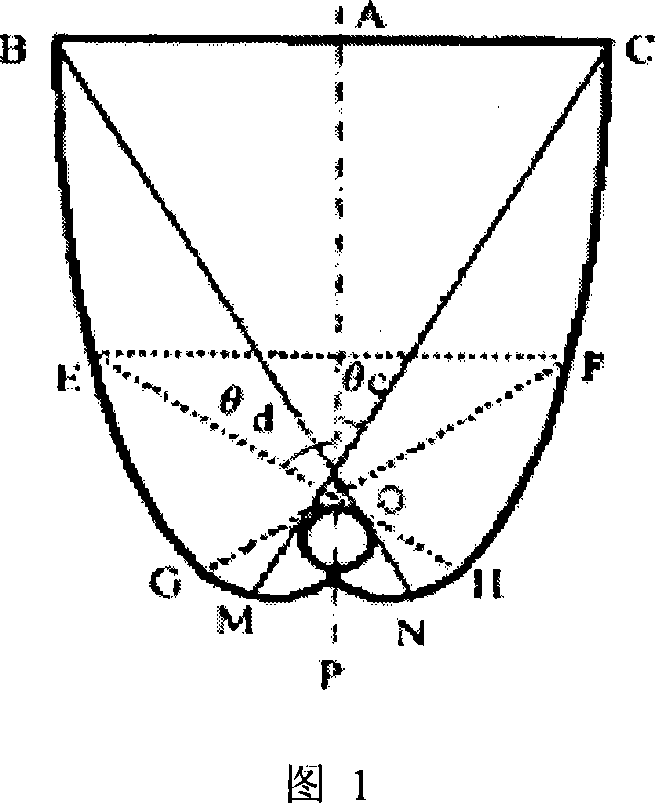

[0022] As shown in Figure 1, B, C, E, and F are the vertices of the cross-section of the compound parabolic condenser 3 without truncation and truncation, respectively, and M, N, G, and H are the half acceptance angles θ, respectively. c And truncation angle θ d The intersection of the incident outermost light ray and the compound parabolic concentrator 3. The tubular reactor 4 should be placed as close as possible to the apex P of the involute in the CPC to achieve the maximum reception of the reflected light in the CPC by the tubular reactor 4. According to the actual reaction needs and comprehensive consideration of the cost, the CPC can be truncated. As shown in the dotted line EF in Figure 1, the concentration ratio of CPC will decrease at this time, but the cost will also decrease.

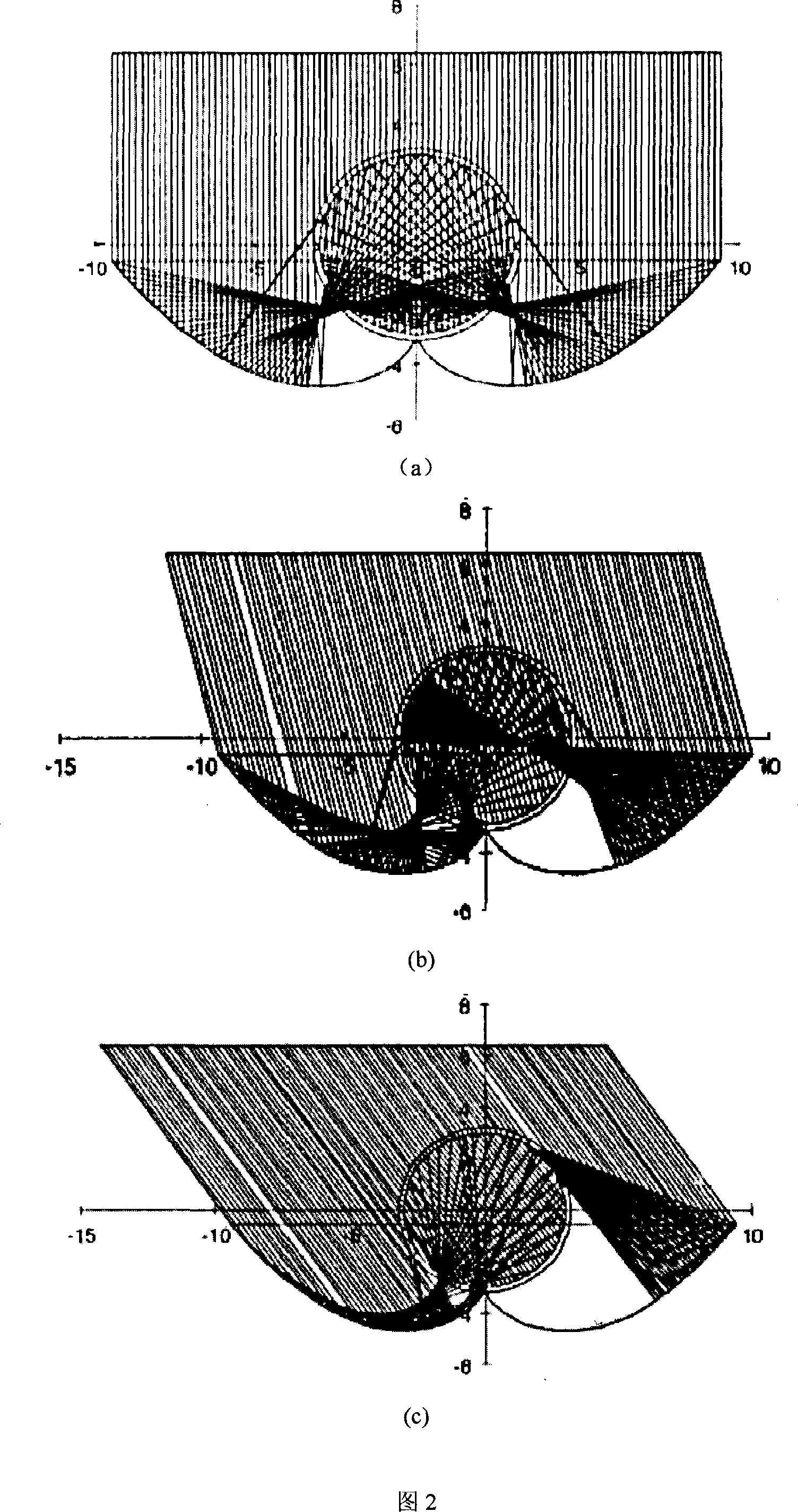

[0023] As shown in Figure 2, each figure shows the convergence of incident light rays from different angles on the surface of the reaction tube in the compound parabolic condenser 3. Under the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com