Classification system for winnowing garbage

A sorting system and garbage technology, which is applied in the direction of magnetic separation, solid separation, and separation of solids from solids with airflow, etc., can solve the problems of easy blockage of the screen, easy knife jamming, and crushing of large pieces of garbage, etc., to achieve the benefit of Effects of stable combustion, improved emission quality, and reduced system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

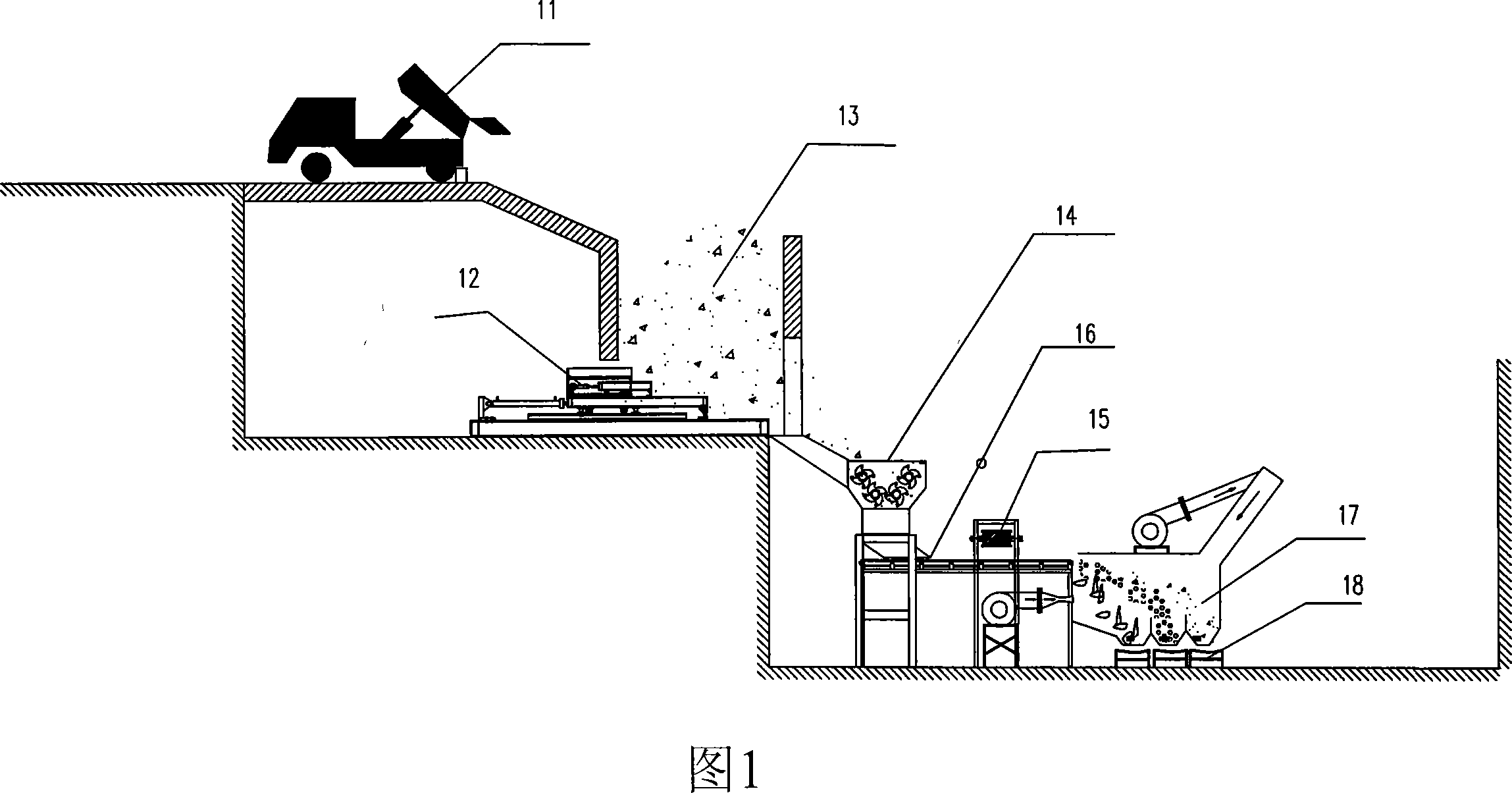

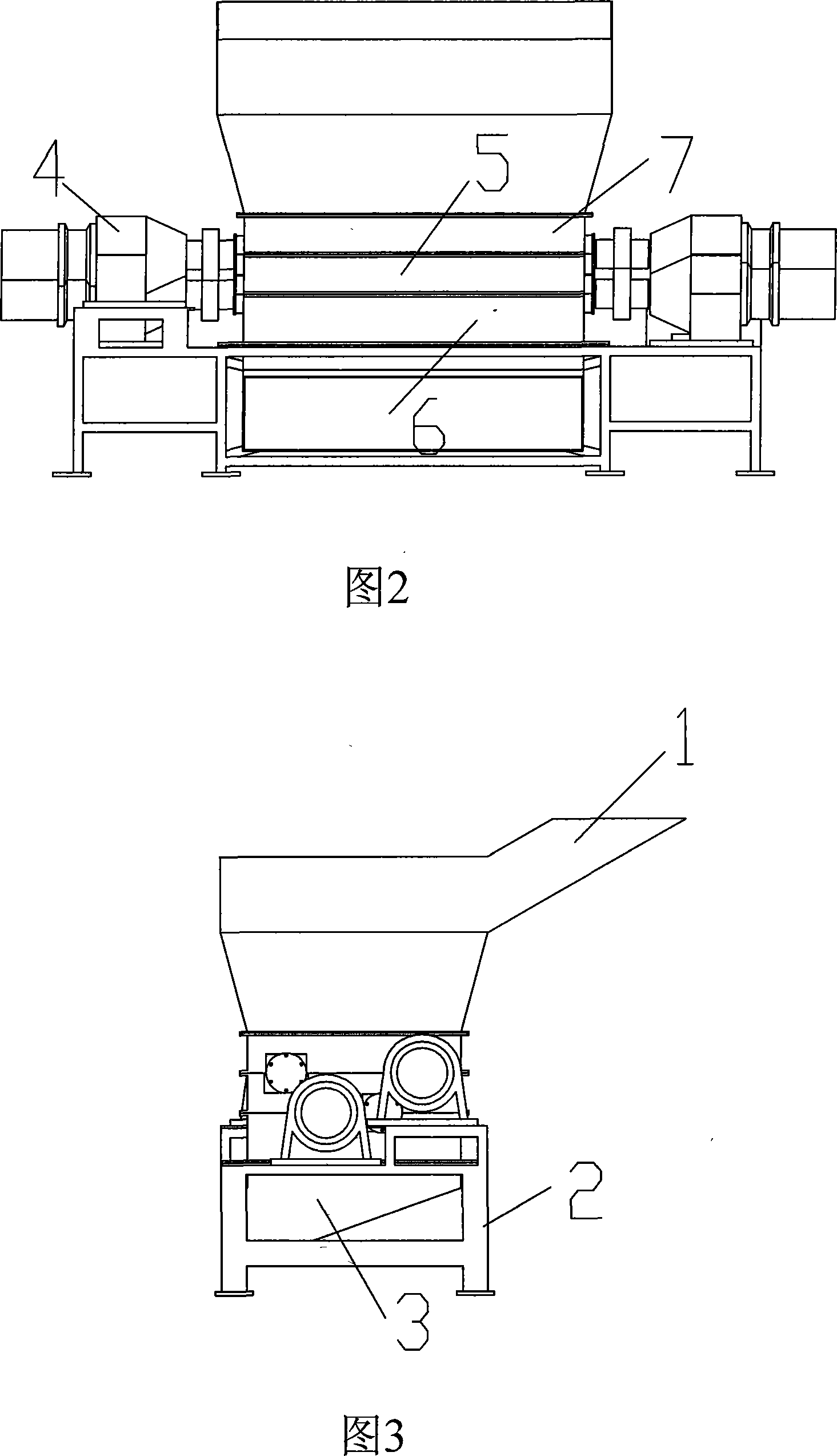

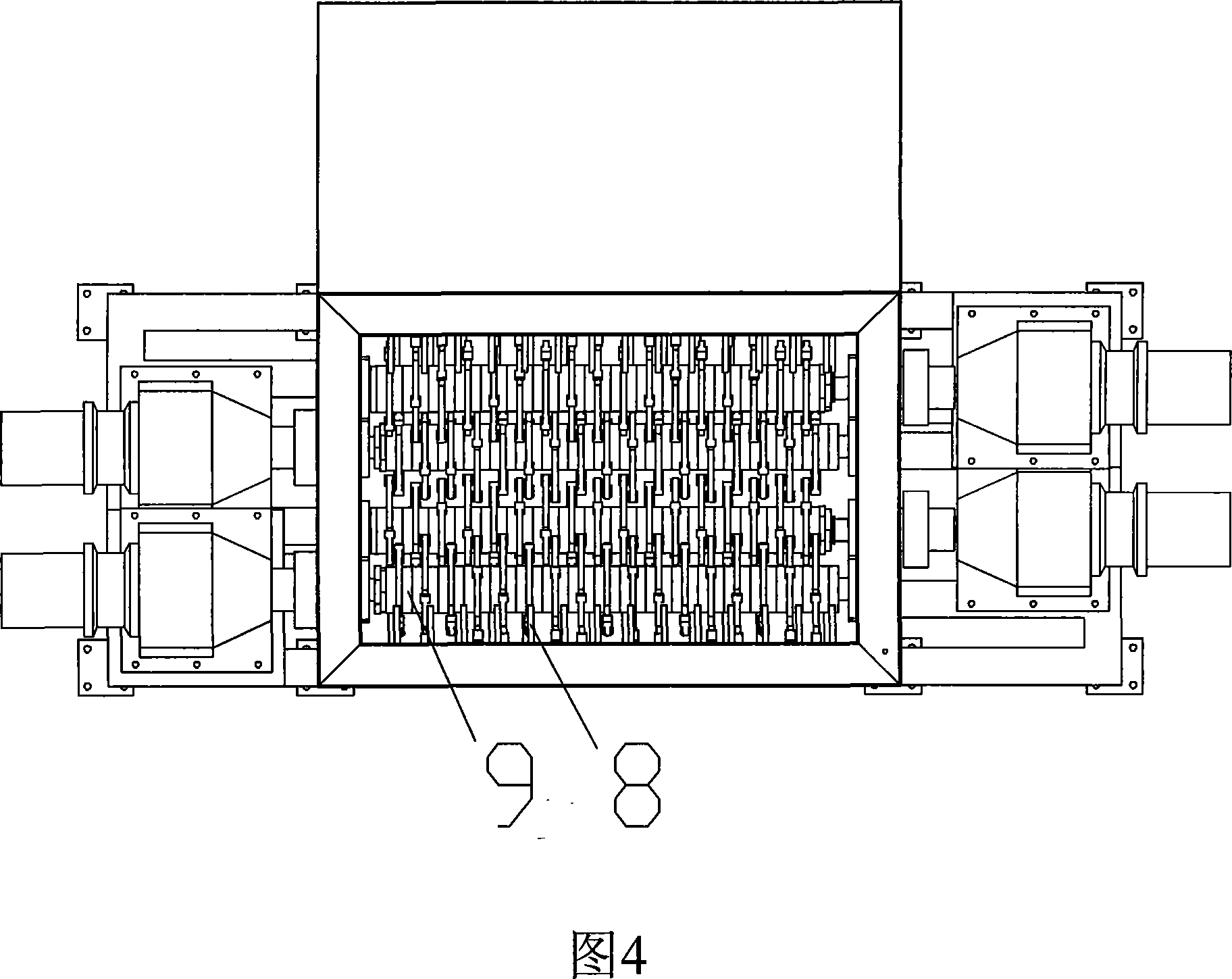

[0019] Referring to Fig. 1, the rubbish winnowing sorting system of the present invention, by feeder 12, material storage pit 13, rubbish breaker 14, magnetic force separator 15, discharge conveyer belt 16, wind force separator 17, separation A material conveyor belt 18 is formed; wherein, the feeder 12 is arranged at the bottom of the storage pit 13, the discharge port of the storage pit 13 is connected with the feed port of the garbage crusher 14, and the discharge port of the garbage crusher 14 is facing At the front end of the discharge conveyor belt, the magnetic separator 15 is arranged above the discharge conveyor belt 16. The magnetic separator 15 can be of flat plate type or drum type, and can also be equipped with an iron removal receiving device. The rear end is connected to the feed inlet of the wind separator 17, and the discharge outlet of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com