Eight-stroke engine

An engine, eight-stroke technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems that the explosion energy is not fully utilized, the effective energy is not utilized, and the theoretical efficiency is far away. reduction, efficiency, energy saving, environmental protection, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

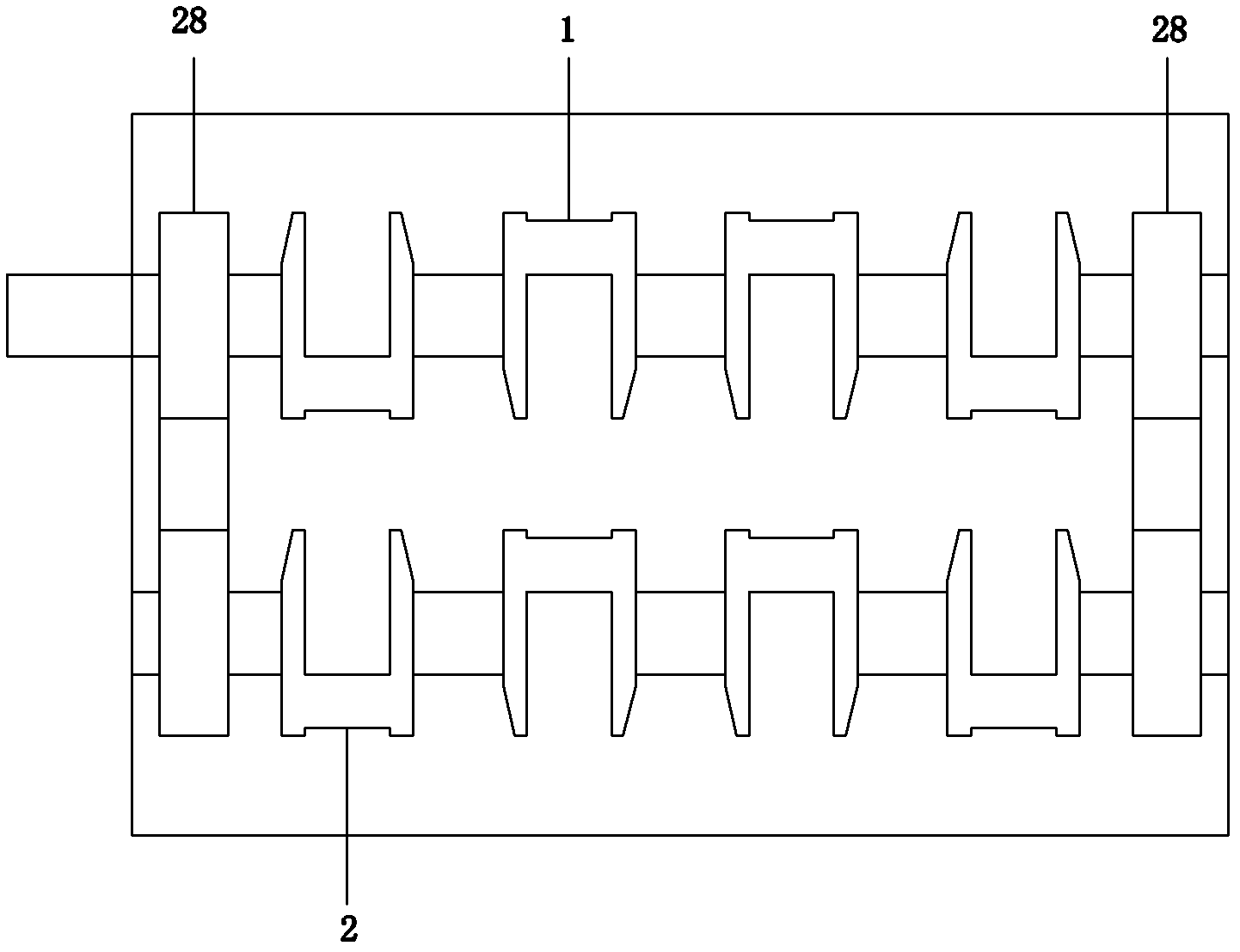

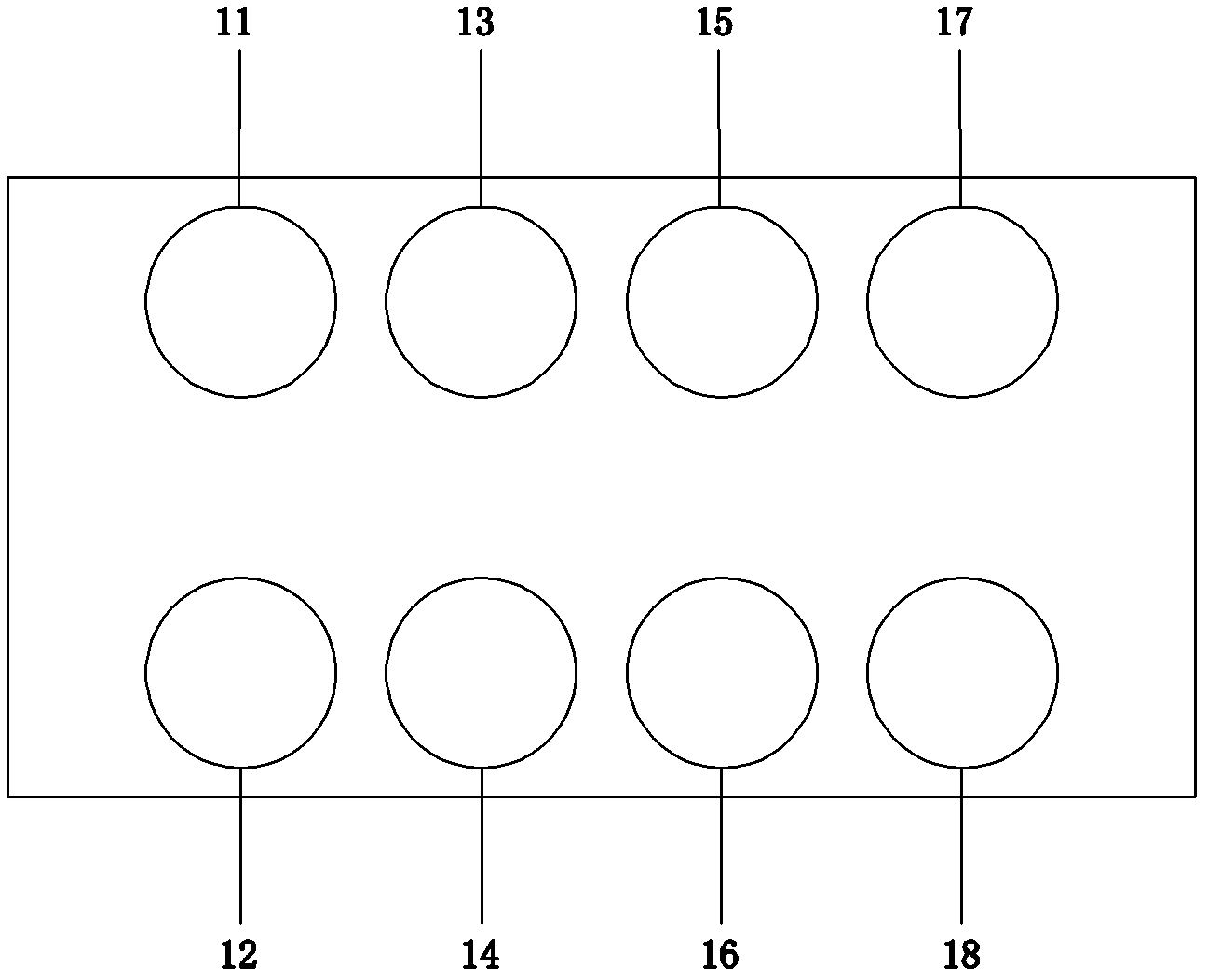

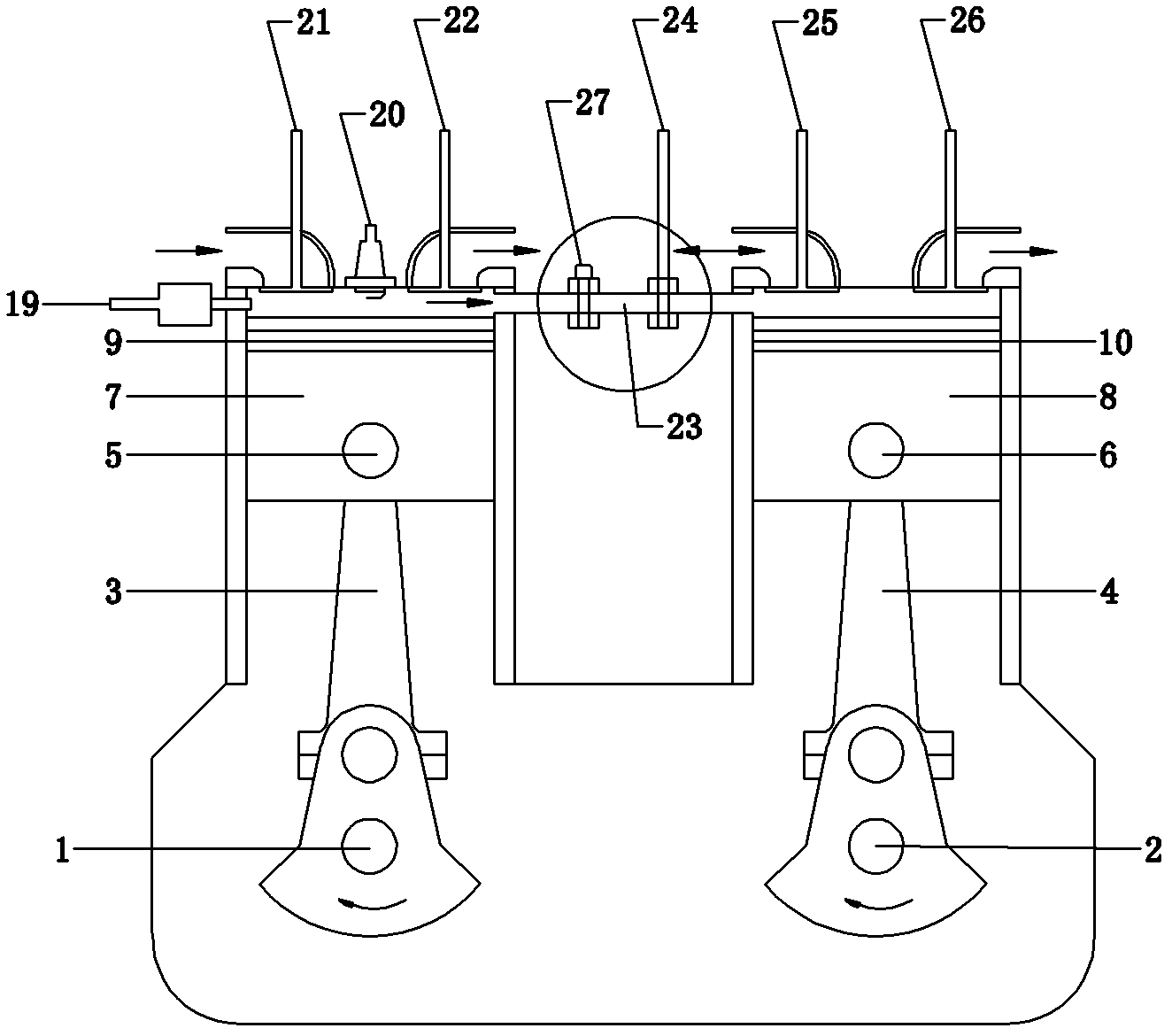

[0038] As shown in the figure, the device of eight-stroke engine: consists of main crankshaft 1, auxiliary crankshaft 2, connecting rod 3, 4, piston pin 5, 6, piston 7, 8, piston ring 9, 10, main cylinder 11, 13, 15 , 17, auxiliary cylinders 12, 14, 16, 18, fuel injectors 19, spark plugs 20, intake valves 21, exhaust valves 22, 26, communication air passages 23, communication valves 24, breathing valves 25, electric valves (electromagnetic valve) 27, synchronizer 28, breathing valve camshaft 29, valve bridge 30.

[0039] There are two identical crankshafts 1 and 2 placed in parallel in the crankcase. Crankshaft 1 is the main crankshaft and has an output end, and crankshaft 2 is the auxiliary crankshaft. The synchronizer 28 makes the two crankshafts rotate at the same time, at the same speed and in the same direction. .

[0040] One row of main cylinders 11, 13, 15, 17 and one row of auxiliary cylinders 12, 14, 16, 18 are arranged in a straight line and horizontally in paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com