Three-stage filtration system for breeding tail water

A three-stage filtration and tail water technology, which is applied in the directions of water/sewage multi-stage treatment, water pollutants, water/sludge/sewage treatment, etc., can solve water pollution, adverse effects of growth, development and reproduction of aquatic economic animals, Destruction of water micro-environmental ecosystem and other problems, to achieve the effect of water quality improvement, optimization of aquaculture environment, and reduction of organic carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

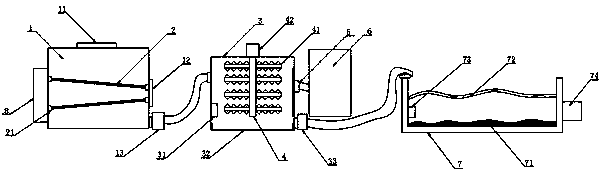

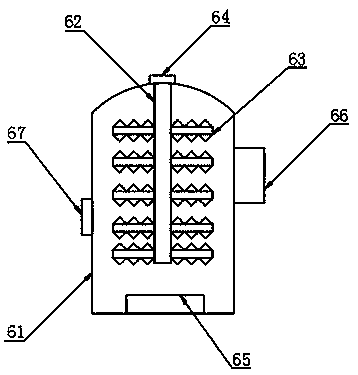

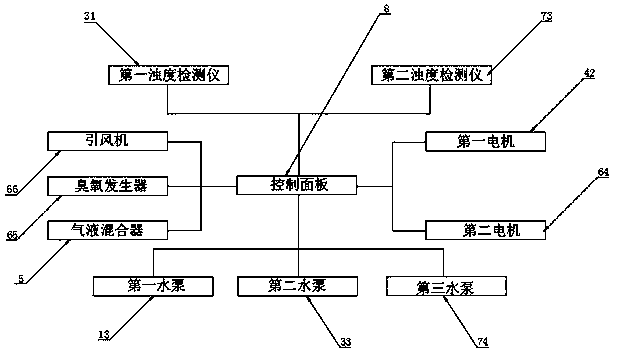

[0022] The present invention provides such Figure 1-3 A three-stage filtration system for aquaculture tail water shown includes a filter chamber 1, and a filter screen 2 is uniformly arranged inside the filter chamber 1, and a treatment chamber 3 is provided on one side of the filter chamber 1, and the treatment chamber 3 The inside is provided with a first rotating shaft 4, and the outside of the treatment chamber 3 is connected with a gas-liquid mixer 5, and the outside of the gas-liquid mixer 5 is connected with an ozone tank 6 through a vent pipe, and the ozone tank 6 includes a tank body 61, The second rotating shaft 62, the second stirring blade 63, the second motor 64, the ozone generator 65, the induced draft fan 66 and the air outlet 67, the outside of the ozone tank 6 is provided with an exposure pool 7, and the surface of one side of the filter chamber 1 is A touch panel 8 is provided.

[0023] The top of the filter chamber 1 is provided with a water inlet 11, the...

Embodiment 2

[0027] A first stirring blade 41 is uniformly arranged on the outside of the exposure pool 7 , and a first motor 42 is arranged on the top of the first rotating shaft 4 , and the first rotating shaft 4 is connected to the first motor 42 by transmission.

[0028] The tank body 61 is arranged on the outside of the processing chamber 3, the inside of the tank body 61 is provided with a second rotating shaft 62, the surface of the second rotating shaft 62 is surrounded by a second stirring blade 63, and the second rotating shaft 62 The top is provided with a second motor 64, the second rotating shaft 62 is connected to the second motor 64 in transmission, the bottom of the inner wall of the tank body 61 is provided with an ozone generator 65, and an induced draft fan 66 is connected to the outside of the tank body 61. One side of the tank body 61 is provided with an air outlet 67, and the air outlet 67 communicates with the gas-liquid mixer 5 through a vent pipe. ,

[0029] Benef...

Embodiment 3

[0031] One side of the inner wall of the processing chamber 3 is provided with a first turbidity detector 31, the bottom of the inner wall of the processing chamber 3 is provided with a storage tank 32, the inside of the storage tank 32 is filled with quicklime, and the outer side of the storage tank 32 is A material opening is provided, and the material opening is arranged on the rear surface of the processing chamber 3 , and a second water pump 33 is provided outside the processing chamber 3 , and the second water pump 33 is connected to the top of the exposure pool 7 through a water pipe.

[0032]The bottom of the inner wall of the exposure pool 7 is provided with a sterilization wetland 71, the inside of the exposure pool 7 is provided with aquatic plants 72, one side of the inner wall of the exposure pool 7 is provided with a second turbidity detector 73, and the outer side of the exposure pool 7 is It is connected with the third water pump 74. Wetland purification is a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com