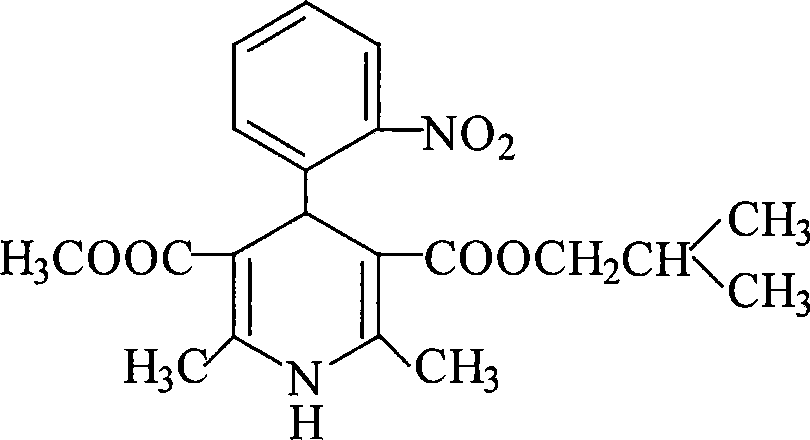

Method for preparing standard of nisoldipine

A technology for nisoldipine and standard products, which is applied in the field of preparation of nisoldipine compound standard products, can solve the problems such as the inability to obtain high-purity nisoldipine standard products, and achieves the effects of simple operation, high product purity and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In a 250ml four-necked reaction flask equipped with a stirrer and a thermometer, 30g of nisoldipine crude product was added in the dark, 60ml of acetone was added, and the temperature was raised to reflux for dissolution under stirring. After the dissolution was completed, heat filtered, and the filtrate was crystallized under stirring to 3-5° C., filtered, washed with cold acetone, and dried to obtain 25.5 g (yield 85%, purity 99.67%) of nisoldipine.

Embodiment 2

[0017] According to Example 1, 30g of nisoldipine crude product was dissolved in 240ml of acetone to obtain 25.3g (yield 84.3%, purity 99.62%) of nisoldipine.

Embodiment 3

[0019] In a 250ml four-necked reaction flask equipped with a stirrer and a thermometer, 30g of nisoldipine crude product was added in the dark, 60ml of acetone was added, and the temperature was raised to reflux for dissolution under stirring. After dissolving, hot filter to crystallize in 75 milliliters of absolute ethanol under stirring, cool to 3~5 ℃, filter, wash with cold acetone, dry to obtain 24.3g (81%, purity 99.83%) nisoldipine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com