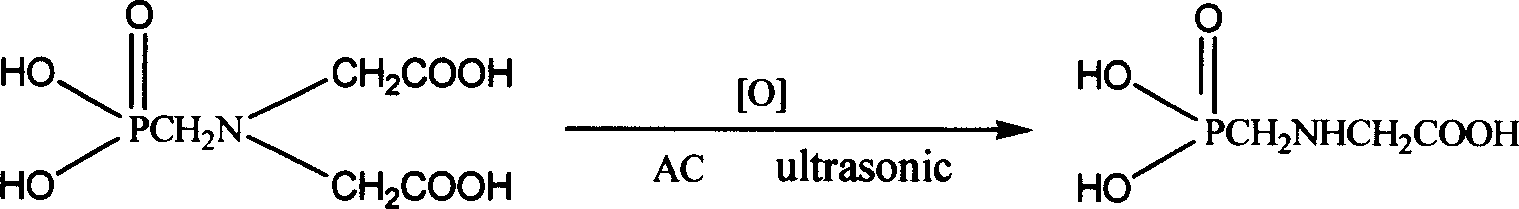

New technique for preparing glyphosate by oxidizing N-Phosphonomethyl iminodiacetic acid in air

A technology of diglyphosate and air, which is applied in the new process field of preparing glyphosate by air oxidation of diglyphosate, which can solve the problems of catalyst recovery difficulty, increased difficulty of product separation and purification, and failure to fundamentally eliminate the use of hydrogen peroxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The ultrasonic generator used in this experiment has a frequency of 25KHz and a power of 100W.

[0028] Add 2.5 grams of gac (charcoal is prepared as a raw material) in the there-necked flask, 50 milliliters of water, 10 grams of PMIDA, heat and stir, feed air into reaction solution, open ultrasonic generator, temperature rises to 40 ℃, detects that diglycophosphine is completely Reaction, the reaction time is 15 hours, the glyphosate reaction selectivity is 89.1%, and finally 6.49g of glyphosate raw powder is obtained, with a content of 99%.

Embodiment 2

[0030] The reclaimed gac in embodiment 1, 100 milliliters of water, 10 grams of PMIDA, heat and stir, feed into air to reaction solution, open ultrasonic generator, temperature rises to 80 ℃, detects that diglyphosate disappears, and reaction stops, and reaction time 12 hours, the glyphosate reaction selectivity was 90.68%, and finally 6.53g of glyphosate powder was obtained, with a content of 99.5%.

Embodiment 3

[0032] The reclaimed gac in embodiment 2, 100 milliliters of water, 10 grams of PMIDA, heat and stir, feed into air to reaction solution, open ultrasonic generator, temperature rises to 90 ℃, detects that diglyphosate disappears, and reaction stops, and reaction time 12 hours, the glyphosate reaction selectivity was 88.4%, and finally 6.24g of glyphosate powder was obtained, with a content of 99.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com