Color frosted plastic-steel section bar, and manufacturing method

A technology of plastic steel and profiles, applied in the direction of slender components, building components, pre-treated surfaces, etc., can solve the problems of poor three-dimensional effect of the surface, complex production process, low production efficiency, etc., and achieve good weather resistance, simple production process, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

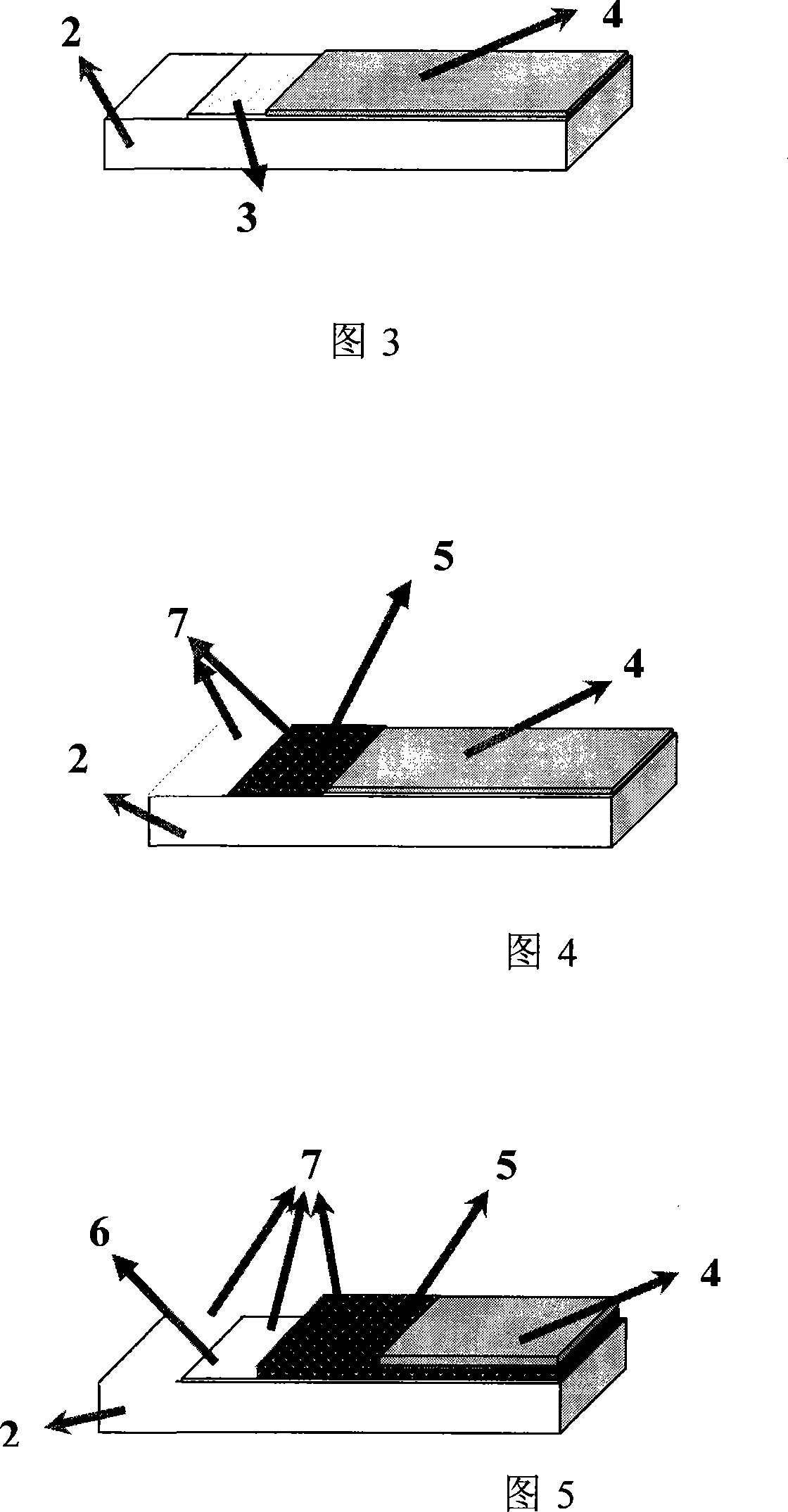

[0050] Example 1: frosted light yellow plastic steel profile

[0051] Please refer to Figure 4. Prepare qualified PVC substrates, place them on the production line, and prepare for production. Adjust the sandblasting transmission speed, spraying transmission speed, curing transmission speed, and traction speed to 20m / min. After the substrate is sandblasted, it enters the spraying equipment, and the yellow UV-curable coating with a mass fraction of 3-8wt% and containing acrylic particles (2-8wt%) is sprayed (the coating should be stirred continuously and maintained at 50°C ~60°C temperature), then enter the curing equipment. In the curing equipment, there are 3 high-pressure mercury lamps with a power of 4.7kw, and 3 metal halide lamps with a power of 3Kw. After the curing is completed, check whether the profile is qualified after passing the traction machine. After reaching the qualified standard, stick PE (polyethylene) protective film.

Embodiment 2

[0052] Example 2: frosted brown plastic-steel profiles

[0053] Prepare qualified PVC substrates, place them on the production line, and prepare for production. The acrylic particle with a mass fraction of 3-8wt% is mixed with the brown ultraviolet light curing paint, stirred and heated to 50-60°C. Adjust the sandblasting transmission speed, spraying transmission speed, curing transmission speed, and traction speed to 18m / min. Started production, after surface sandblasting and paint spraying, it entered the curing equipment, 6 high-pressure mercury lamps with a power of 7.8Kw, and 3 metal halide lamps with a power of 3Kw. After curing, the inspection index reaches the qualified standard, and the PE (polyethylene) protective film is pasted, and the frosted brown plastic-steel profile can be obtained.

Embodiment 3

[0054] Example 3: Frosted green plastic-steel profiles

[0055] Prepare qualified PVC substrates, place them on the production line, and prepare for production. Adjust the sandblasting transmission speed, spraying transmission speed, curing transmission speed, and traction speed to 18m / min. After the substrate is sandblasted, it enters the spraying equipment, and is sprayed with a green UV-curable coating containing acrylic particles (3-8wt%) (the coating should be stirred continuously and maintained at a temperature of about 52°C), and then enters the curing process. equipment. In the curing equipment, there are 3 high-pressure mercury lamps with a power of 4.7kw, and 3 metal halide lamps with a power of 3Kw. After the curing is completed, check whether the profile is qualified after passing the traction machine. After reaching the qualified standard, stick PE (polyethylene) protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap