Gravity drive pump of microflow controlled chip system

A microfluidic chip, gravity-driven technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of reduced flow rate, fluid-driven pressure drop, etc., to achieve the effect of constant flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

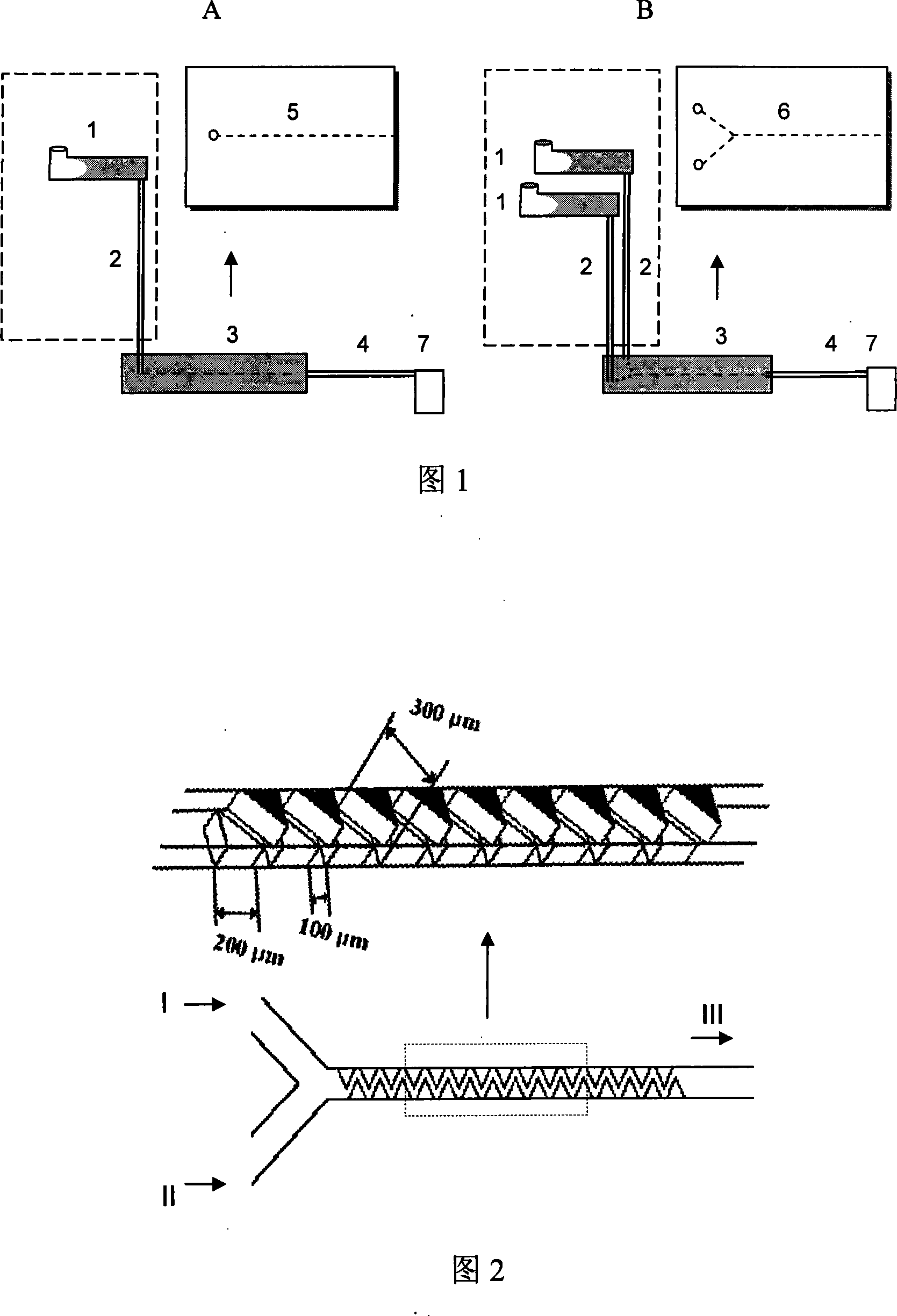

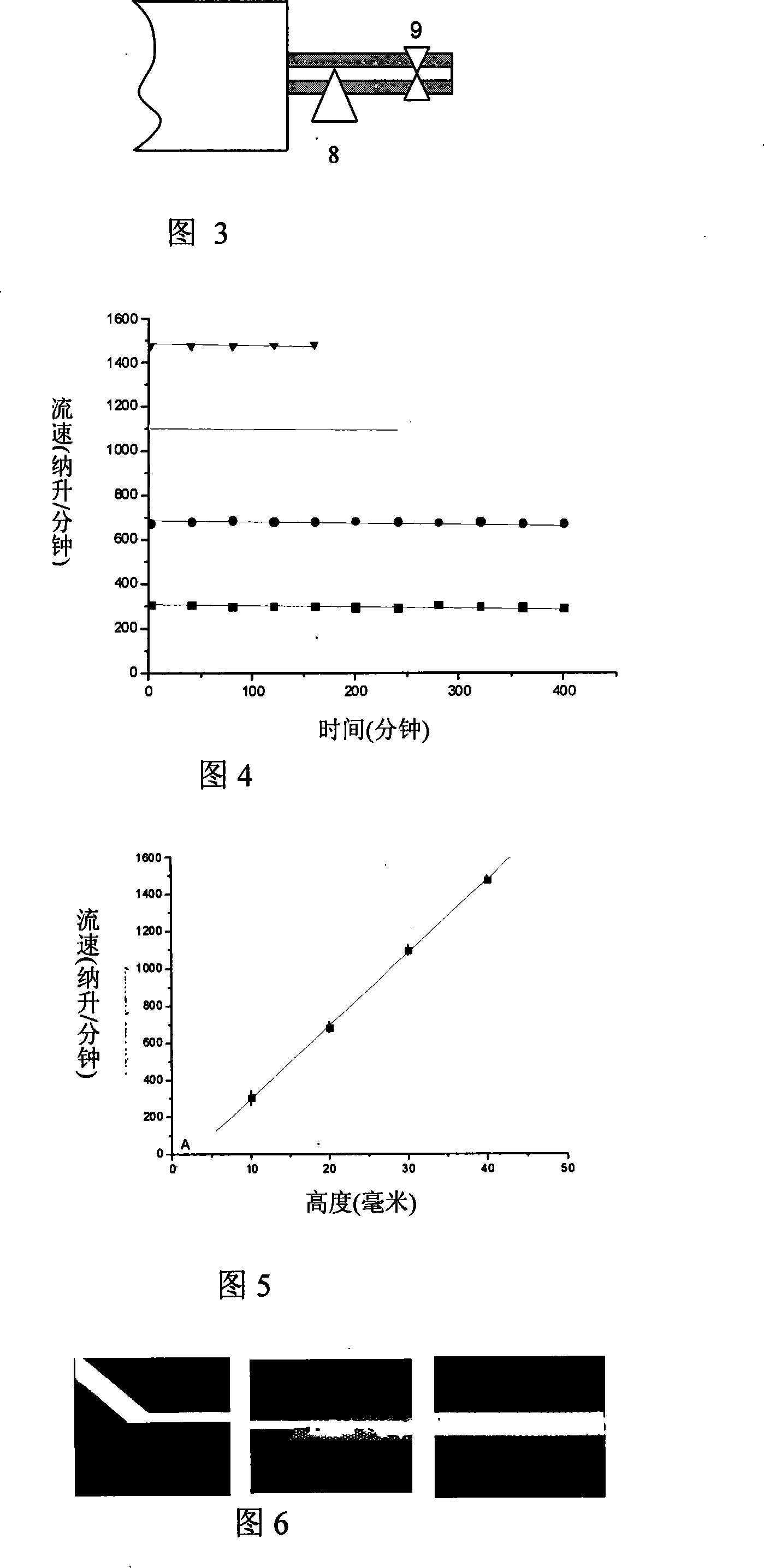

[0025] As shown in Fig. 1A, it is a constant flow gravity-driven pump of the microfluidic chip system provided by the present invention. It is composed of a liquid reservoir 1 placed horizontally, a connecting conduit 2, a microfluidic chip 3 with a single microchannel and a flow rate regulating tube 4 connected in sequence. The volume of the reservoir 1 is 500 microliters, placed horizontally; the connecting conduit 2 is a PEEK tube with an inner diameter of 254 microns and an outer diameter of 1.6 mm; the equivalent inner diameter of the microfluidic chip 3 is 300 microns, and the length is 2 cm channel chip; the flow rate is adjusted Tube 4 is a 3 cm long plastic catheter with an inner diameter of 100 microns and an outer diameter of 1.6 mm. The driving fluid is deionized water, and 7 is an outlet reservoir. The microfluidic chip 3 is made of PDMS material and a crocodile-tooth-shaped mixing channel. The chip has two inlets (I, II) opening up to accept the fluid from the r...

Embodiment 2

[0027] Fig. 1B is a microfluidic chip system provided by the present invention with constant flow and gravity double pumps. Dual reservoirs and channel chips enable binary drive operation. It is composed of two horizontally placed liquid reservoirs 1, two connecting conduits 2, a microfluidic chip 3 with a Y-shaped microchannel and a flow rate regulating tube 4 connected in sequence. The dimensions of the microfluidic chip of the Y-shaped microchannel are shown in Figure 2. The dimensions of other corresponding components are the same as in Example 1, and the driving fluid is deoxyribonucleic acid (DNA) solution of 16mer single-stranded labeled TAMRA and TET. The flow rate was 634 nL / min. Other microfluidic chips 3 and flow rate regulating tubes 4 are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com