Silicon steel sulfuric acid refining system cleaning process

A silicon steel acid and process technology, applied in the field of cold-rolled silicon steel pickling system cleaning process, can solve problems such as treatment capacity limitation, secondary pollution and blockage of sewage discharge system, and achieve the effect of reducing waste liquid discharge and improving operation reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

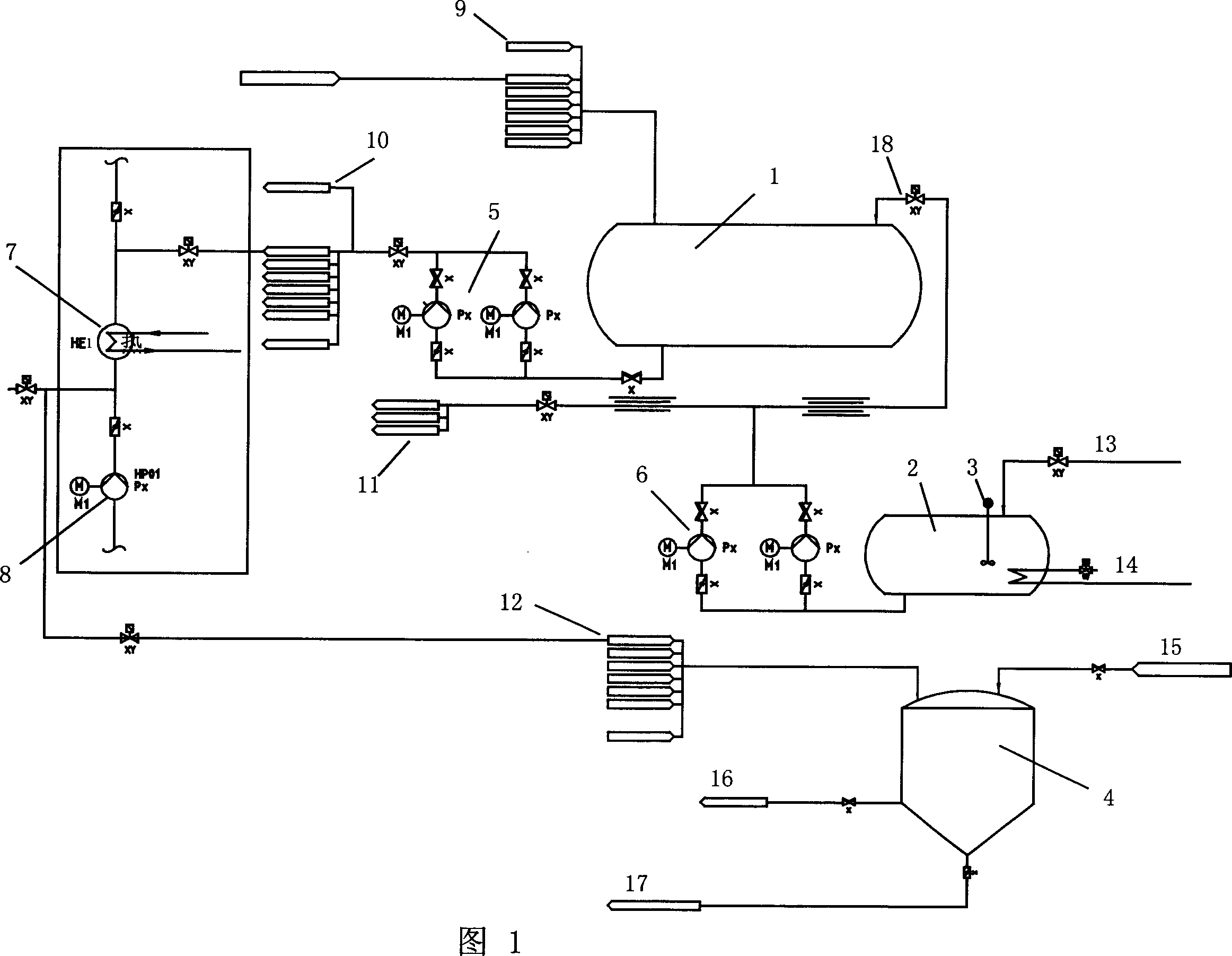

[0028] Referring to Figure 1, a silicon steel pickling system cleaning process, the cleaning process for the pickling system is:

[0029] Step 1, stop the unit;

[0030] Step 2, the acid in the acid tank is returned to the acid tank after shutdown;

[0031] Step 3, use the unit circulating pump 8 to transport the acid in the acid tank to the settling tank, and when the liquid level in the acid tank drops to the minimum alarm level of the pump operation, stop the pump and discharge the residual acid directly to the ditch;

[0032] Step 4, after the remaining acid is emptied, close all the evacuation valves;

[0033] Step 5, open the valve of the acid tank to supplement the industrial water, and when the liquid level reaches 40%, start the pump 6 of the original solution of the lye supplement, and calculate the supplementary original solution according to the concentration of the original solution, such as 30% lye, and the volume of the acid tank volume, finally adjust the lye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com