Crankcase of internal combustion engine

A technology of crankcase and internal combustion engine, applied in the direction of internal combustion piston engine, combustion engine, engine cooling, etc., can solve problems such as complex structure, and achieve the effect of preventing dew condensation, improving rigidity, and improving prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

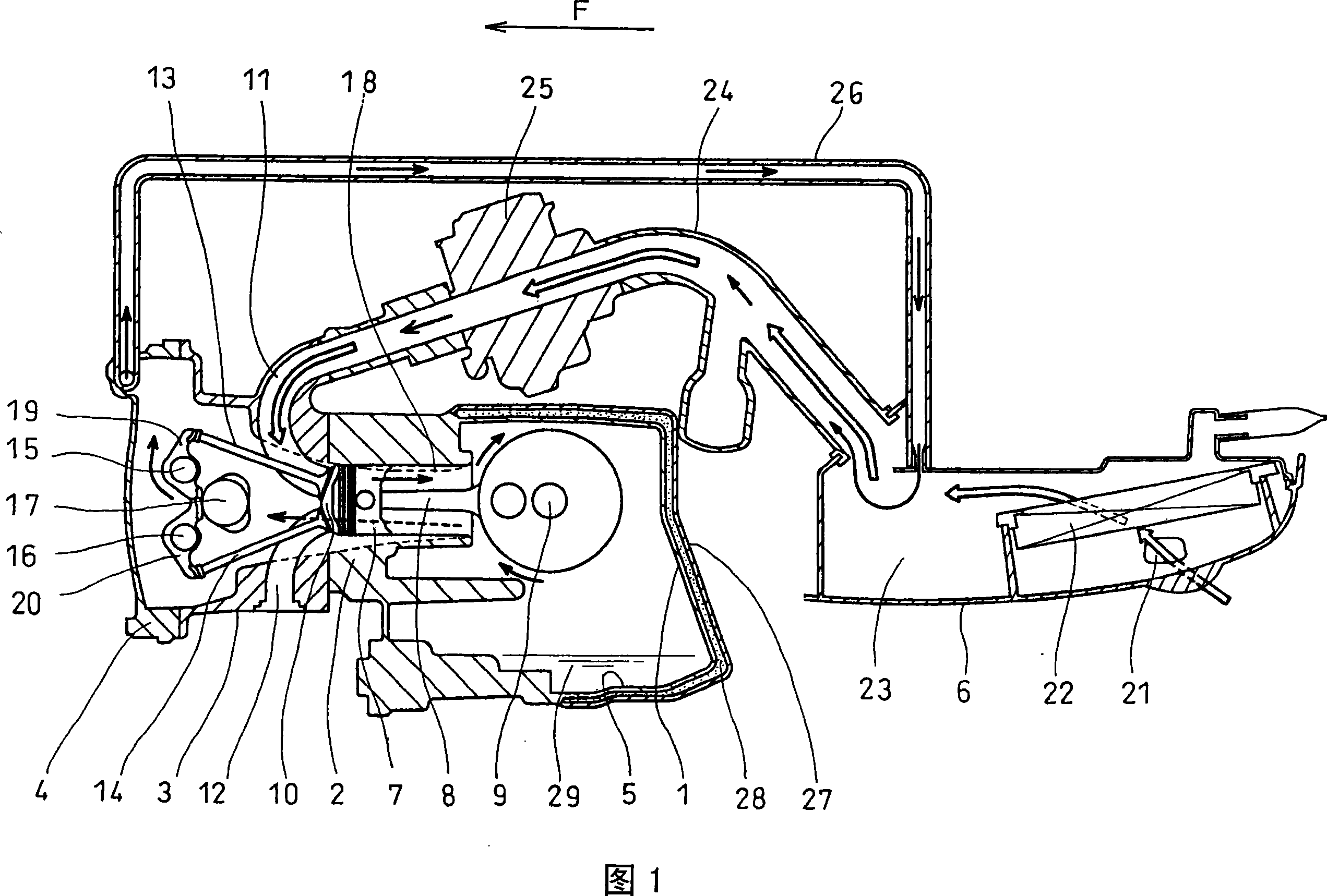

[0041] 1 is a sectional view showing the main part of a wet sump lubrication type 4-stroke internal combustion engine equivalent to the first embodiment of the present invention from the left side, with arrow F pointing forward of the internal combustion engine. In Fig. 1, an internal combustion engine is composed of a crankcase 1, a cylinder 2 integrated with the crankcase 1, a cylinder head 3, a cover 4, an oil pan 5 and an air cleaner 6 at the bottom of the crankcase. Piston 7 is slidably housed in cylinder 2 and connected to crankshaft 9 via connecting rod 8 .

[0042]The combustion chamber 10 is arranged on the side of the piston 7 in the cylinder head 3 . An intake port 11 and an exhaust port 12 are provided on the cylinder head 3 and have their respective inner ends open to the combustion chamber 10 . At the respective inner end openings of the intake port 11 and the exhaust port 12, an intake valve 13 and an exhaust valve 14 for opening and closing the respective open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com