Long life ferroalloy sacrificial anode

A sacrificial anode and ferroalloy technology, which is applied in the field of long-life ferroalloy sacrificial anodes, can solve problems such as structural pressure resistance and short service life, and achieve the effect of increasing service life and increasing anode weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

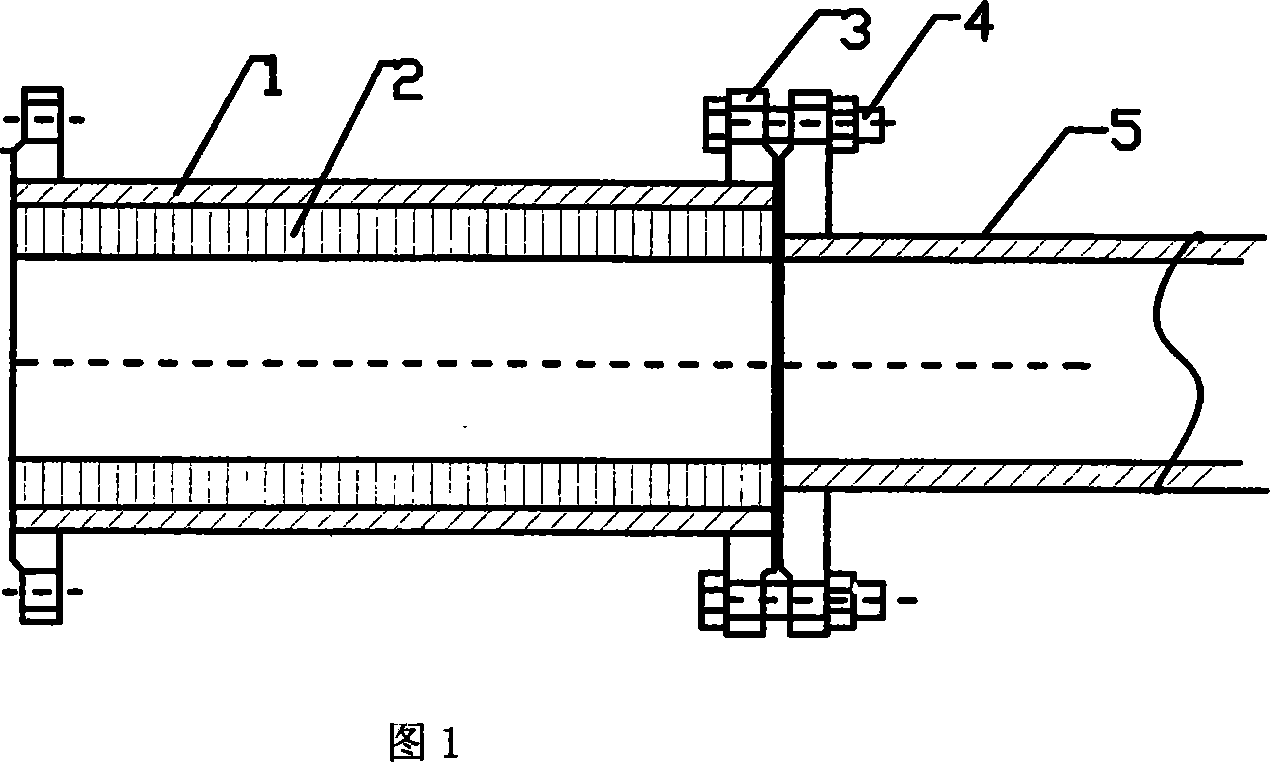

[0014] In this implementation, taking the protection of copper seawater pipelines as an example, the material of the anode outer casing 1 is selected to be copper, and the material composition weight percentage of the sacrificial tubular anode body 2 is: Mn, 1-6%; Cr, 1-5%; Al, 0.1~0.5% iron alloy anode (iron content is 88~98%), the performance index of this anode body material is: specific gravity: 7.84g / cm3; open circuit potential: -0.68~-0.72V (SCE); working potential: - 0.61~-0.59V (SCE); Actual capacitance > 920A.h / Kg; Current efficiency > 95%; Anode dissolves evenly. The length L of the anode body structure is determined according to the design life requirement or the installation space requirement of a specific seawater pipeline. The inner diameter of the sacrificial tubular anode body 2 is the same as that of the protected pipeline 5, and it is connected to the seawater pipeline flange through a flange during installation. The pipeline 5 is connected; when replacing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com