Bottle cap ring-cutting machine cap-hanging device

The technology of a cover hanging device and a ring cutting machine can be applied to metal processing and other directions, and can solve the problems of high cost, difficult installation and maintenance, complicated structure of the cover hanging device, etc., and achieve the effects of low maintenance cost, simple structure and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

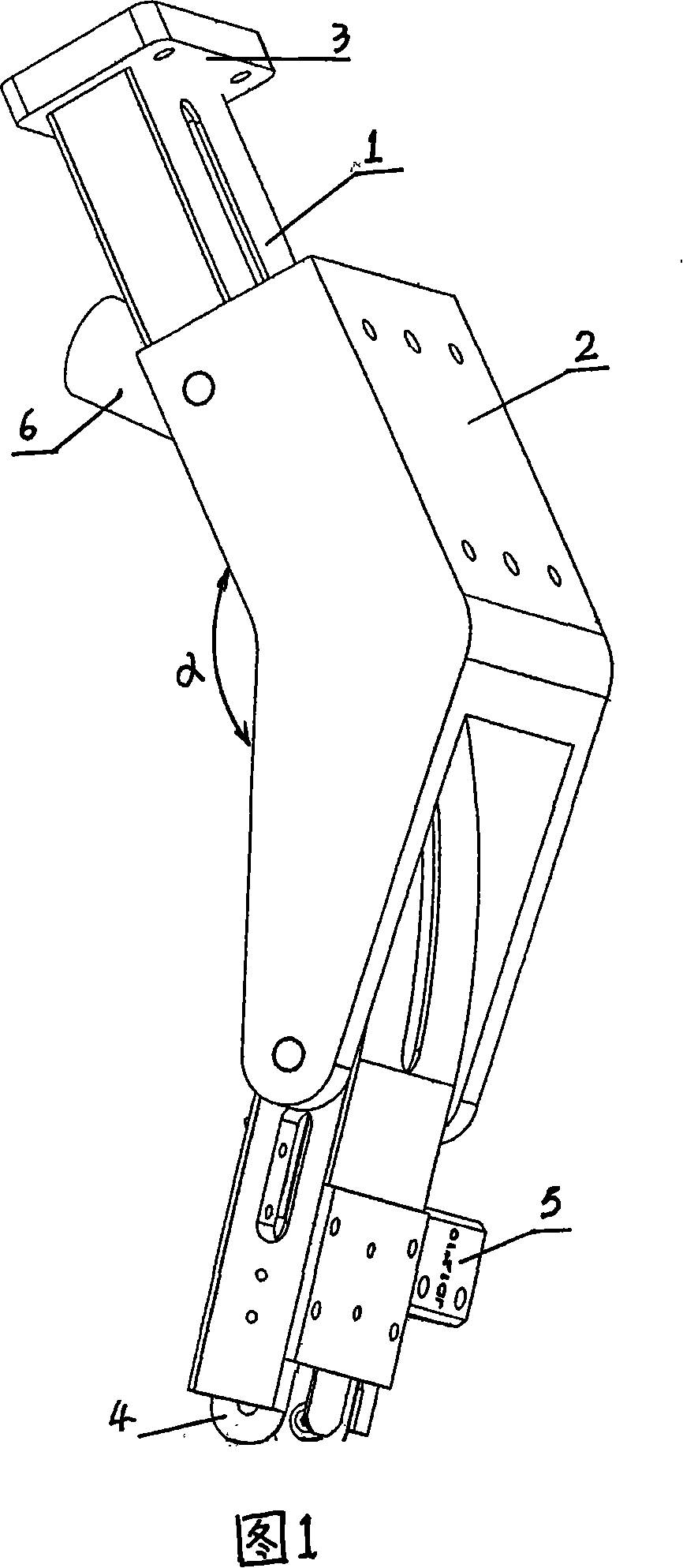

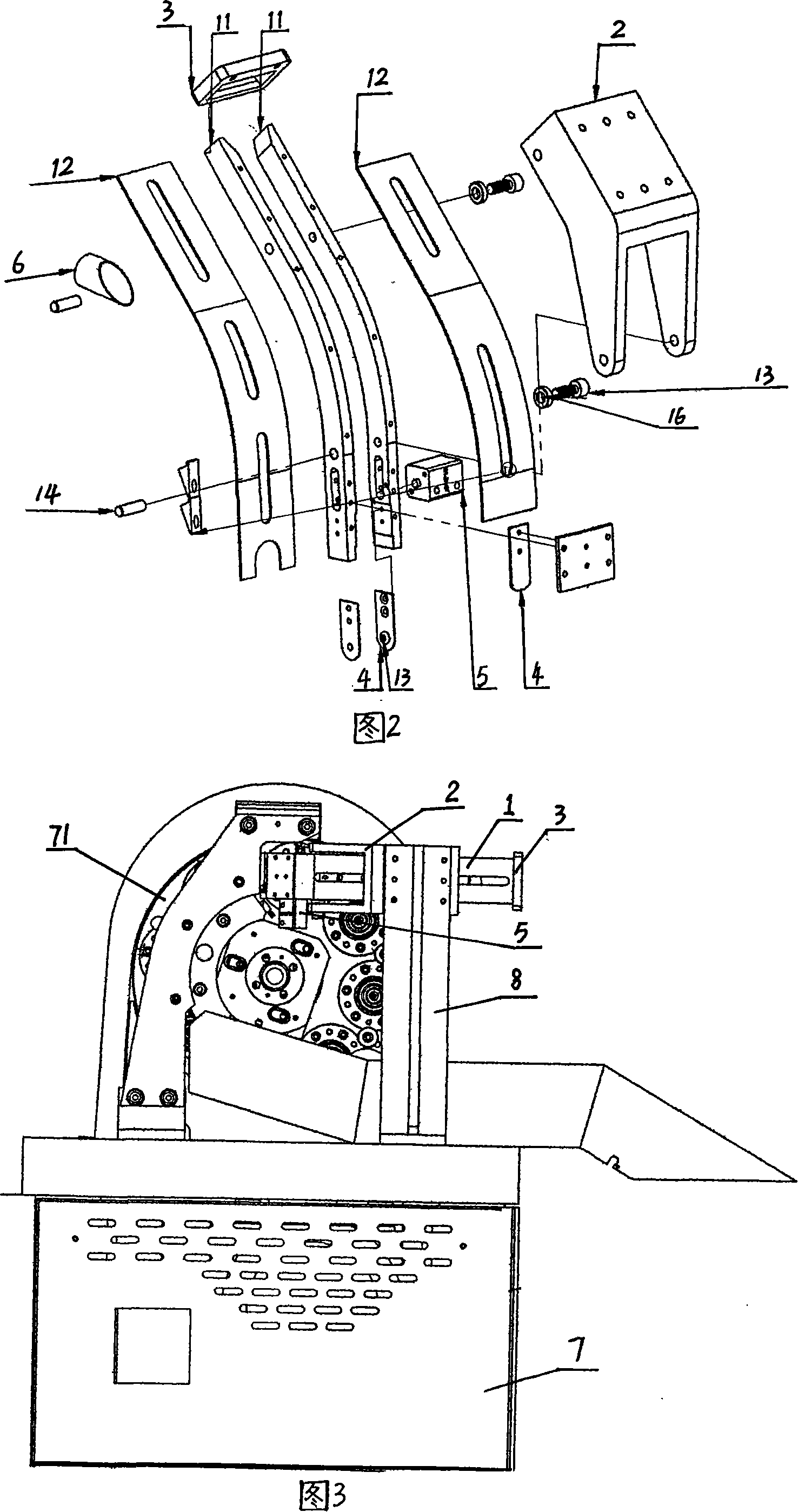

[0020] Referring to Fig. 1, this embodiment includes a bottle cap conveying track 1 and a fixed seat 2, the bottle cap conveying track 1 is fixed in the fixed seat 2; the input end of the bottle cap conveying track 1 is provided with a butt joint 3 externally connected to the output port of the injection molding machine, The output end of the bottle cap conveying track 1 is provided with an elastic sheet 4; the bottle cap conveying track 1 is bow-shaped, and the output port of the bottle cap conveying track 1 is inclined, so that the bottle cap at the output port of the bottle cap conveying track is at an inclination; A cylinder 5 is arranged before the output end of the cap conveying track 1, and the control input end of the cylinder 5 is connected to the signal output end of the speed measuring solenoid valve, and the detection input end of the speed measuring solenoid valve is connected to the knife rest rotating shaft of the bottle cap ring cutting machine.

[0021] Referri...

specific Embodiment 2

[0027] The feature of this embodiment is that the bottle cap conveying track 1 can be integrally formed. The included angle at the bend of the bottle cap conveying track 1 can be α=105°, α=115°, α=135°, α=150°, α=165°, α=175°. All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com