Three-dimensional glass porous media model for microcosmic oil drive and manufacturing method thereof

A three-dimensional glass and porous media technology, applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problem of not being able to ensure high-fidelity oil displacement process at the same time, and achieve high-fidelity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

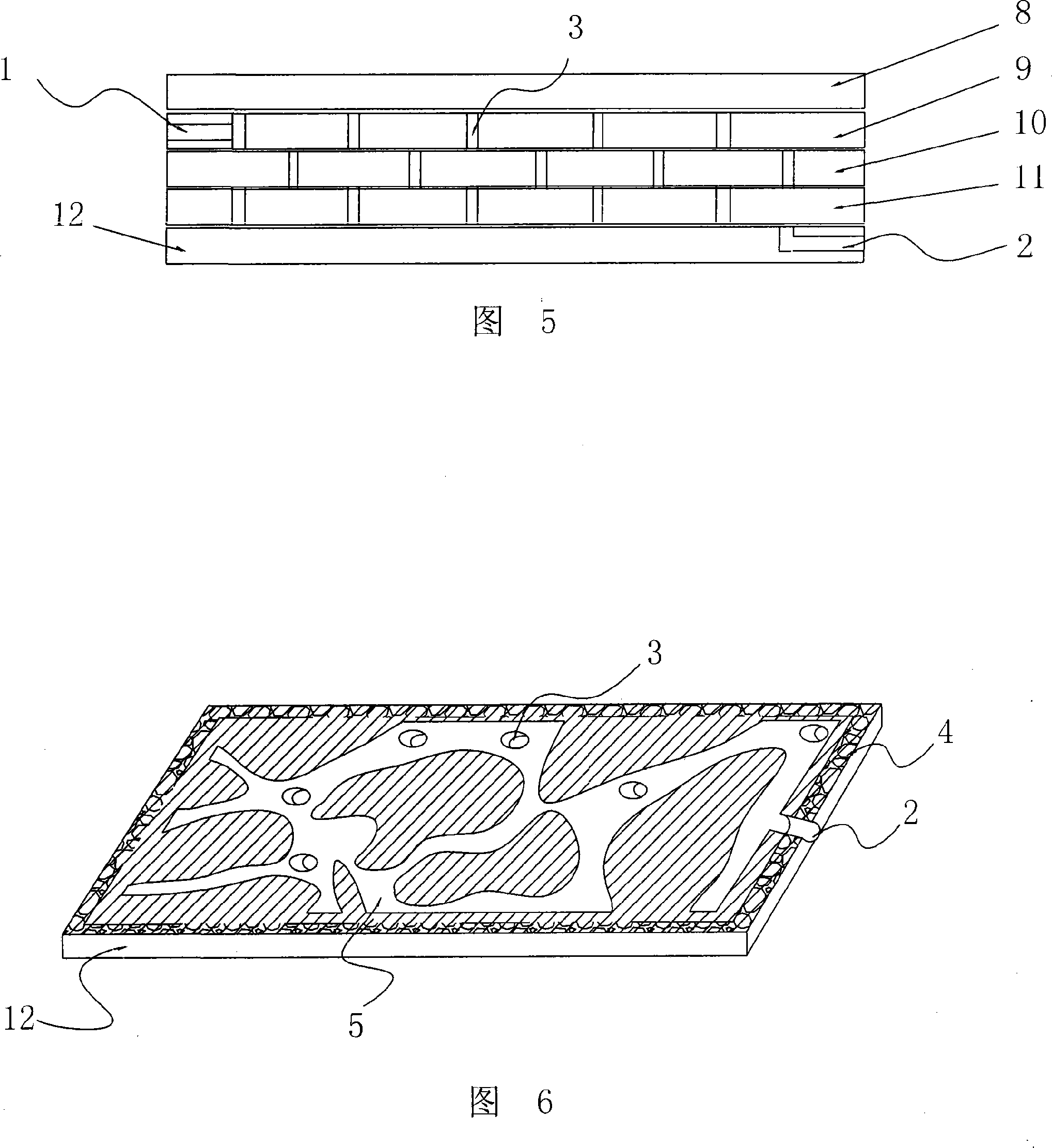

[0045] The glass sheet for making the substrate adopts the PYREX 7740 type glass produced by Corning Corporation of the United States.

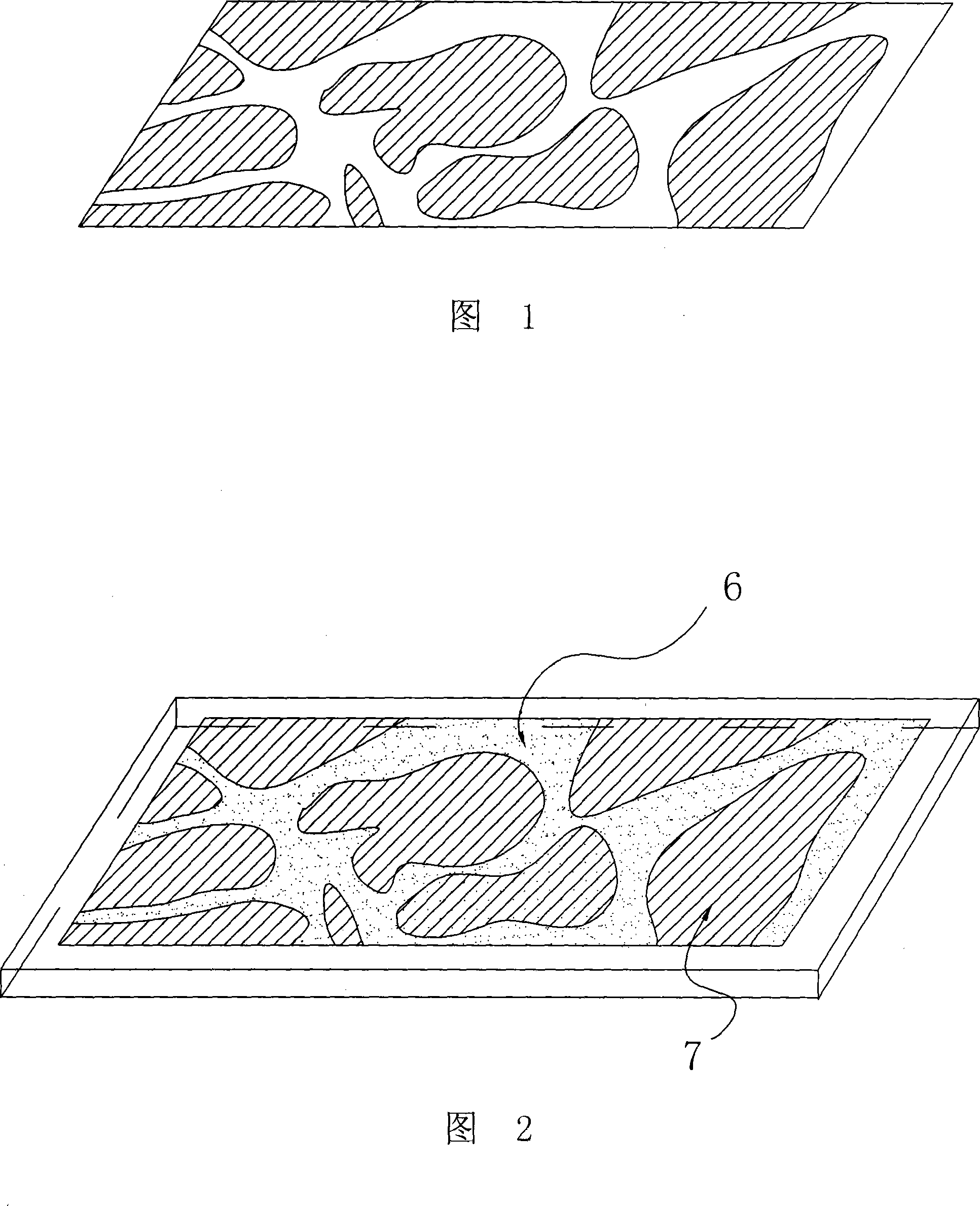

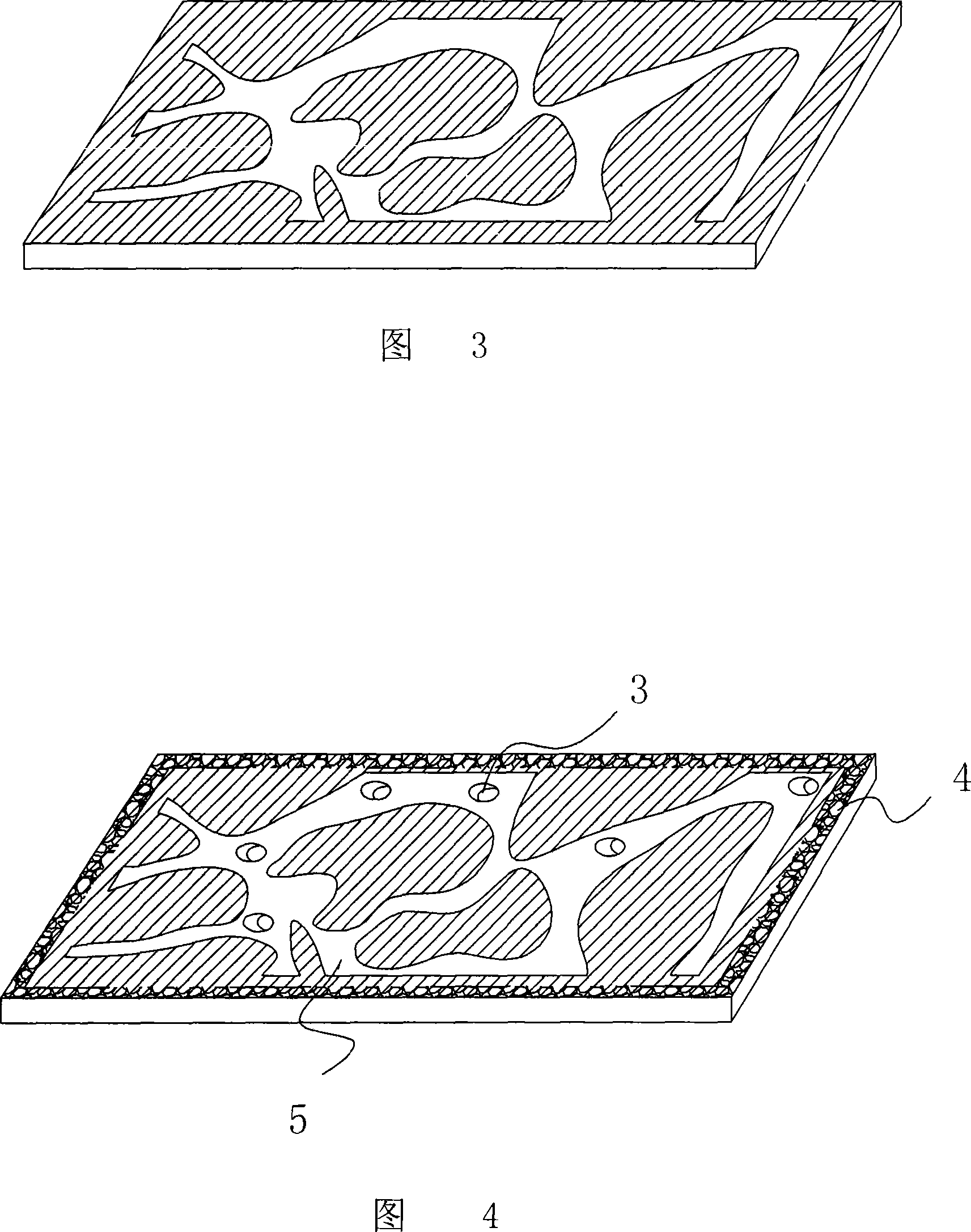

[0046] First, a mask is established on the surface of the glass sheet, and then the planar pore channels of the core are etched on the surface of the glass sheet according to the planar pore image of the natural core obtained by coring.

[0047] The process of creating a mask is:

[0048] (1) cleaning. The polished glass was ultrasonically cleaned with acetone and alcohol for 5 minutes, then soaked in potassium dichromate for one day to remove the oil on the surface, rinsed with deionized water, and dried with nitrogen flow.

[0049] (2) drying. Dry the cleaned glass piece in an oven at 130°C for one hour to enhance the surface activity of the glass.

[0050] (3) Double-sided coating. The dried glass sheet is plated with a 120 nm thick chromium film on both sides.

[0051] (4) Coat BP-212 type photoresist on both sides of the glass sheet...

Embodiment 2

[0062] The glass sheet for making the model adopts the PYREX 7740 type glass produced by Corning Corporation of the United States.

[0063] Firstly, a mask is established on the glass surface. The process flow is: (1) Cleaning, ultrasonically clean the polished glass with acetone and alcohol for 5 minutes, then soak it in potassium dichromate for one day to remove the oil on the surface, and then use deionized Rinse with water and blow dry with a stream of nitrogen. (2) Drying, the glass is dried in an oven at 130° C. for one hour to enhance the surface activity of the glass. (3) Double-sided coating, each of the two sides of the glass is coated with a chrome film with a thickness of 120nm. (4) Glue coating on both sides, using BP-212 photoresist, the speed of spinning the glue is 1500r / min, the throwing time of glue is 30s, and the thickness of the glue is about 2 microns. (5) Pre-baking, pre-baking in a thermostat at 90°C for 15 minutes. (6) Single-sided photolithography,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com