Spigot-and-socket type quick joint for copper pipe

A socket-type, fast technology, applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, through components, etc., can solve the problems of long welding time, large welding equipment volume, high price, etc., and achieves wide application occasions, The effect of fast installation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

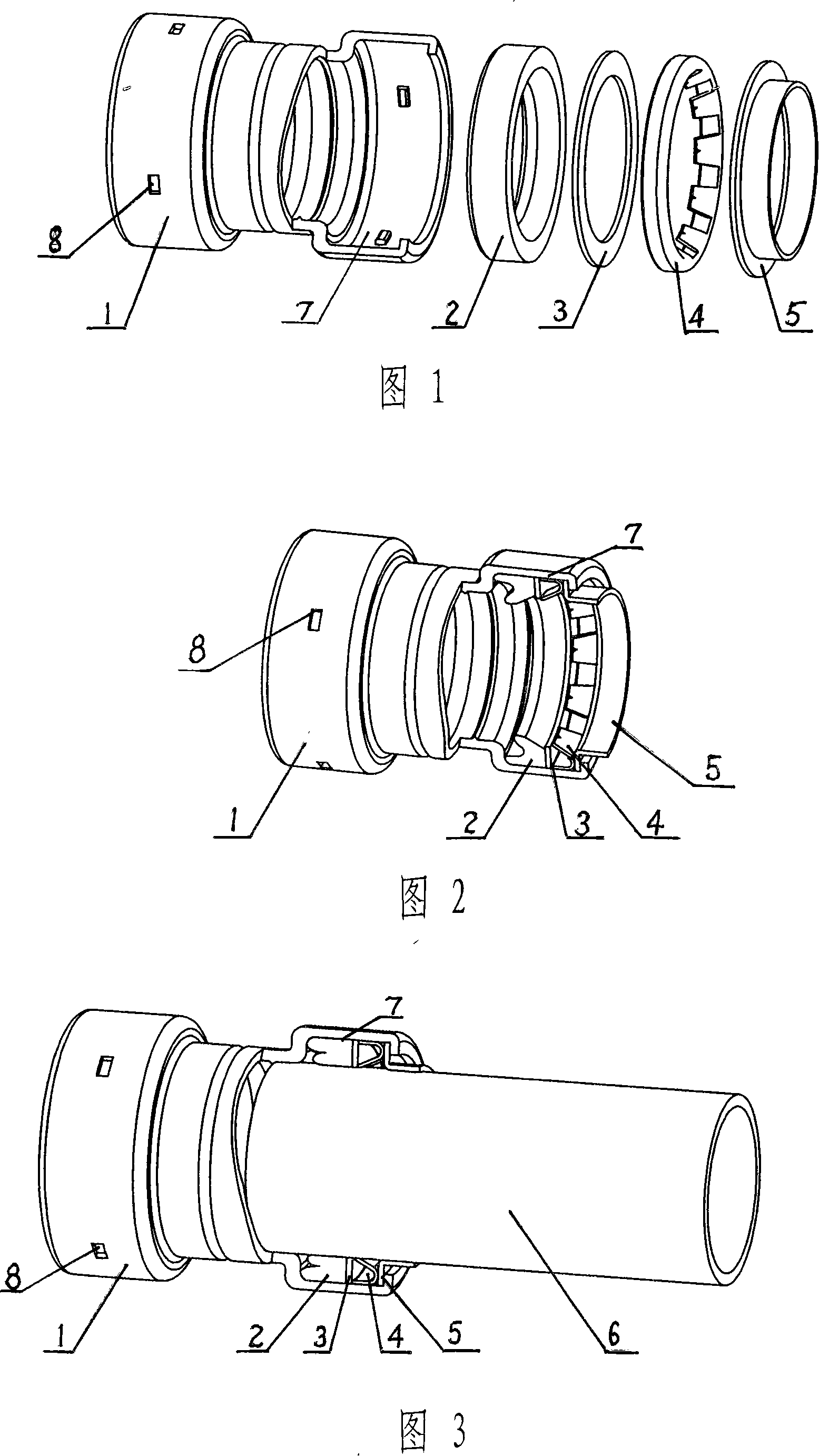

[0011] Referring to Fig. 1-Fig. 3, a copper tube socket-type quick connector includes a joint body 1, and the two ends of the joint body 1 have a joint flared part 7, and the joint flared part 7 is uniformly punched inward along the radial direction. Four pits 8, the four pits 8 are 3mm away from the root of the flared part 7 of the joint, and the Y-shaped rubber sealing ring 2, the positioning ring 3, and the clamping ring made of stainless steel plate are placed in the flared part 7 of the joint in sequence 4. The guide ring 5 and the four pits 8 become the positioning points of the positioning ring 3, and the positioning ring 3 separates the clamping ring 4 and the Y-shaped rubber sealing ring 2, forming a special seal in the joint flared part 7 The ring cavity, the clamping ring 4 is a V-shaped ring with an inward barb.

[0012] Referring to Fig. 3, the Y-shaped rubber sealing ring 2 has a minimum size of Φ14.5mm processed without deformation and compression, and is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com