Liquid crystal display panel and method for producing same, device comprising same

A liquid crystal display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of easily burnt pixel electrodes, unable to repair bright spot defect pixels, difficult to control the temperature of laser beam heating, etc., to reduce the heating temperature , Prevent the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following detailed description sets forth some exemplary embodiments of the invention by way of illustration only. As those skilled in the art will realize, the present invention can be applied in many different ways and should not be limited to the embodiments set forth herein. In addition, in the present invention, when a certain layer is referred to as being located or disposed between two other layers, it should be broadly understood that the layer can either directly border on the other two layers, or be connected to the other two layers through other layers. The two floors are separated.

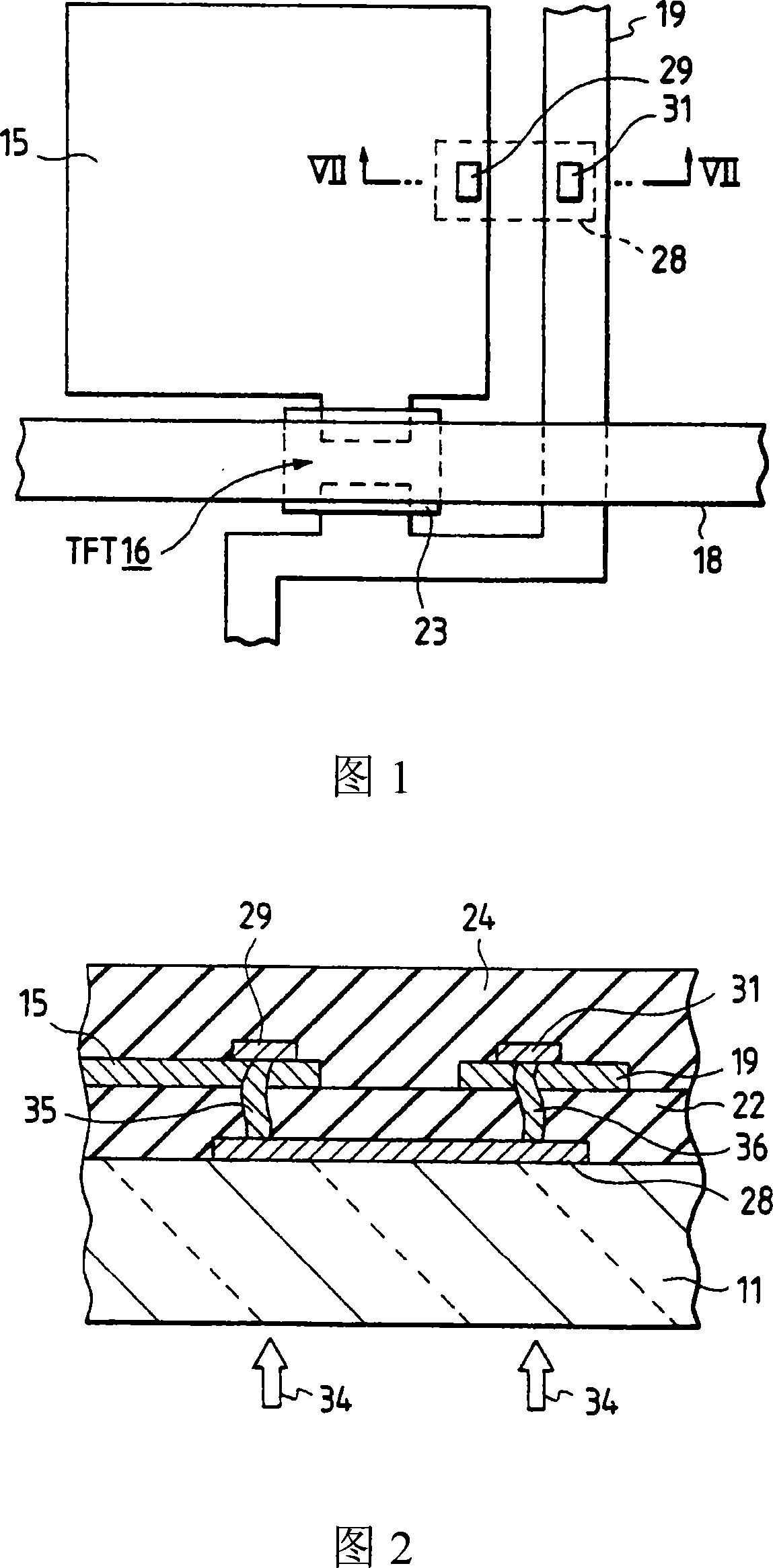

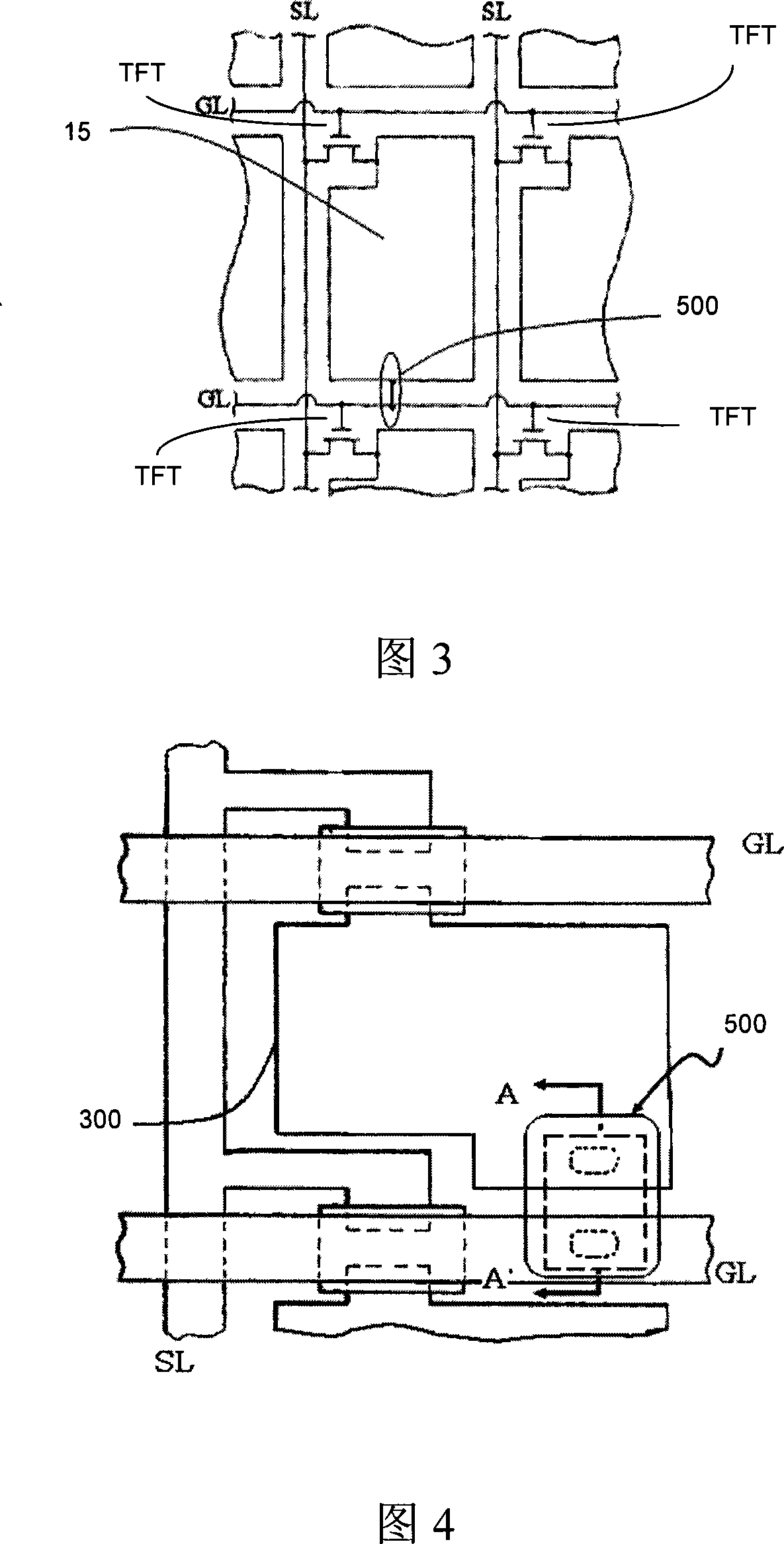

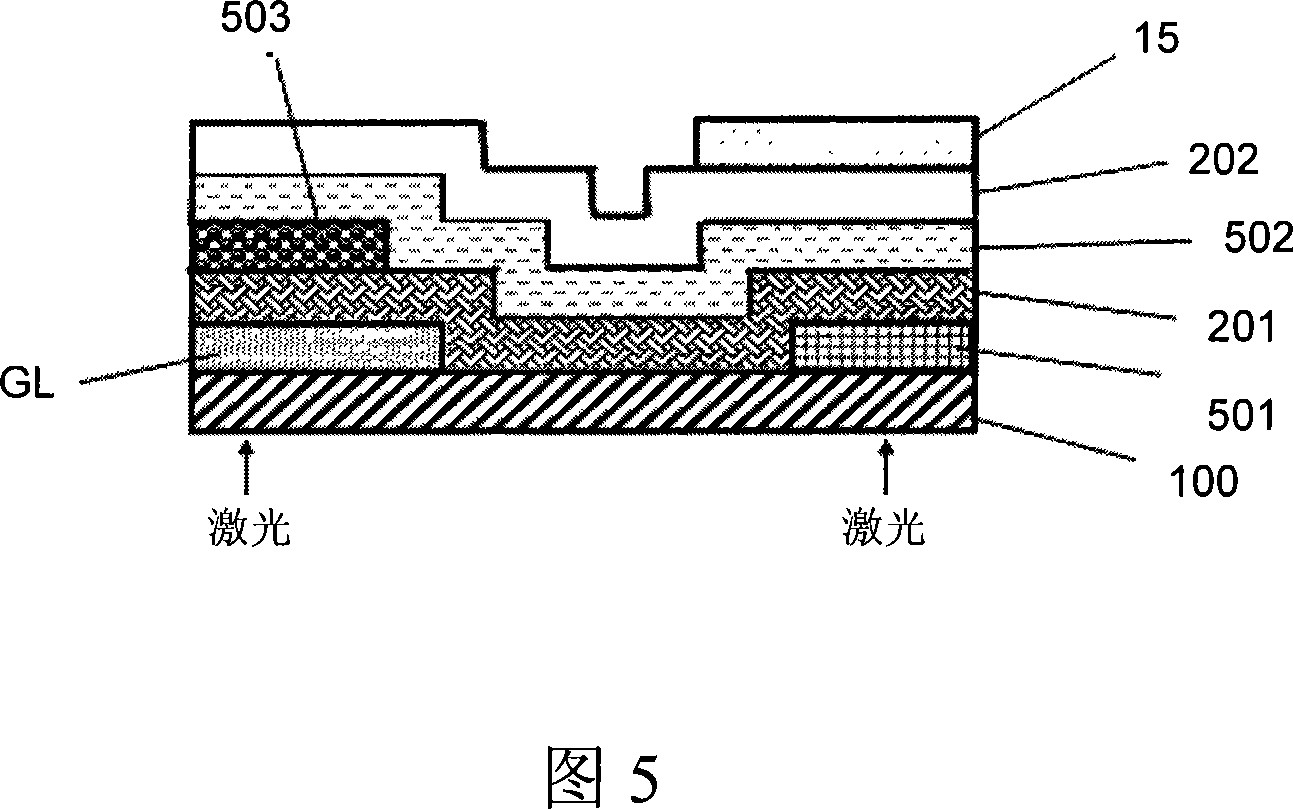

[0030] FIG. 3 is a schematic plan view of a pixel array substrate of a typical liquid crystal display panel. The pixel array of the liquid crystal display panel is formed on a substrate (not shown), and as shown in FIG. The pixel electrodes 15 near the area and the thin film transistors TFT that connect each pixel electrode 15 with the gate line and the data line, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com