Urea-based lubricating grease composition

A technology of grease composition and urea-based grease, which is applied in the fields of roller bearings and electric power steering devices, and can solve problems such as low torque performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

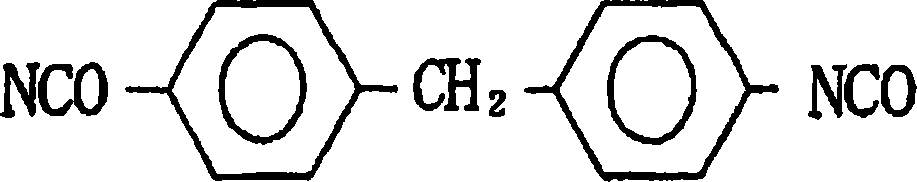

Method used

Image

Examples

Embodiment 1-4

[0063] The base oil and the diisocyanate were placed in an airtight grease trial production device according to the compounding ratio shown in Table 1, and heated to 60° C. while stirring. Starting materials prepared by mixing and dissolving various amines and base oils were fed from a hopper, and the mixture was allowed to react. In order to complete the reaction, it was heated to 170° C. while stirring, maintained for 30 minutes, then cooled to 80° C., and the additives in the compounding ratio shown in Table 1 were added. As an oxidation inhibitor, an additional 1.0% of octyldianiline was added (ie in addition to the rest of the formulation which was considered 100%). The grease was obtained by processing in three rolls after allowing to cool to about 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com