Petrochemical industry standard first-class extreme pressure lithium complex grease and preparation method thereof

A technology of complex lithium base and grease, applied in the field of grease, can solve the problem of unable to meet the performance requirements of extreme pressure lithium complex grease, and achieve the effect of ultra-long service life and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a petrochemical industry standard first-class extreme-pressure complex lithium-based grease, comprising the steps of:

[0038] Step 1: Mix and stir the paraffin base oil, higher fatty acid, lithium hydroxide monohydrate, and compound acid evenly, heat to 135-145° C., react for 3-4 hours, and add appropriate amount of water at intervals during the reaction to obtain saponified products;

[0039] Step 2: Raise the temperature of the saponified compound to 230-235°C, keep it for 5-10min, and naturally cool it to 90-110°C, and then mix it with tackifier, composite antioxidant, extreme pressure anti-wear agent, self-healing additive and corrosion inhibitor. Mixed with synthetic base oil and stirred evenly, and the finished product is obtained after grinding;

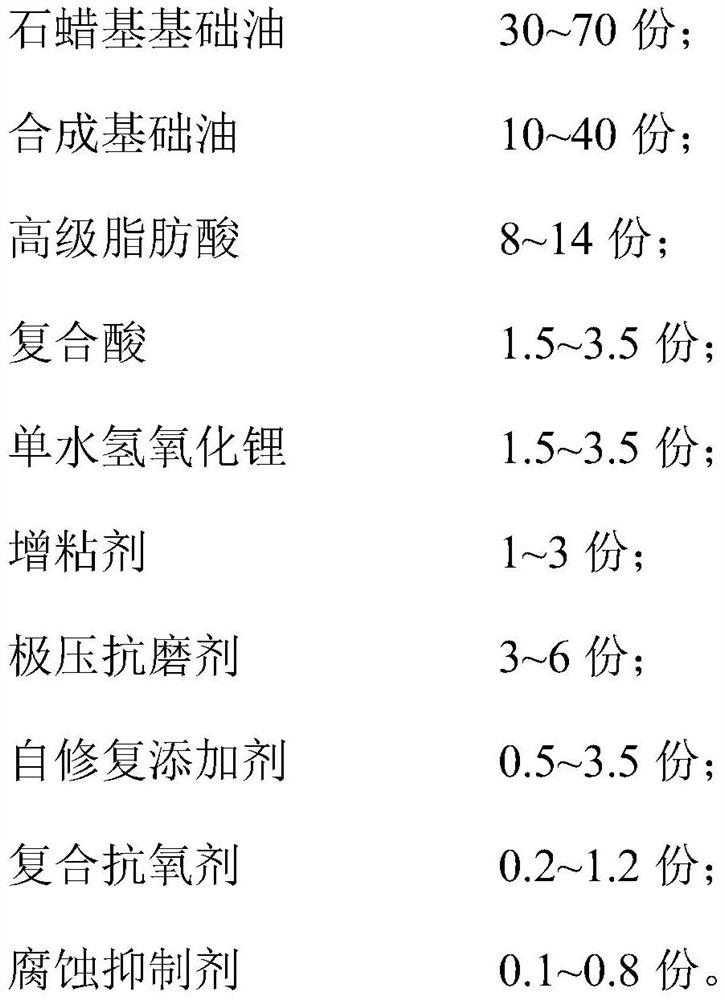

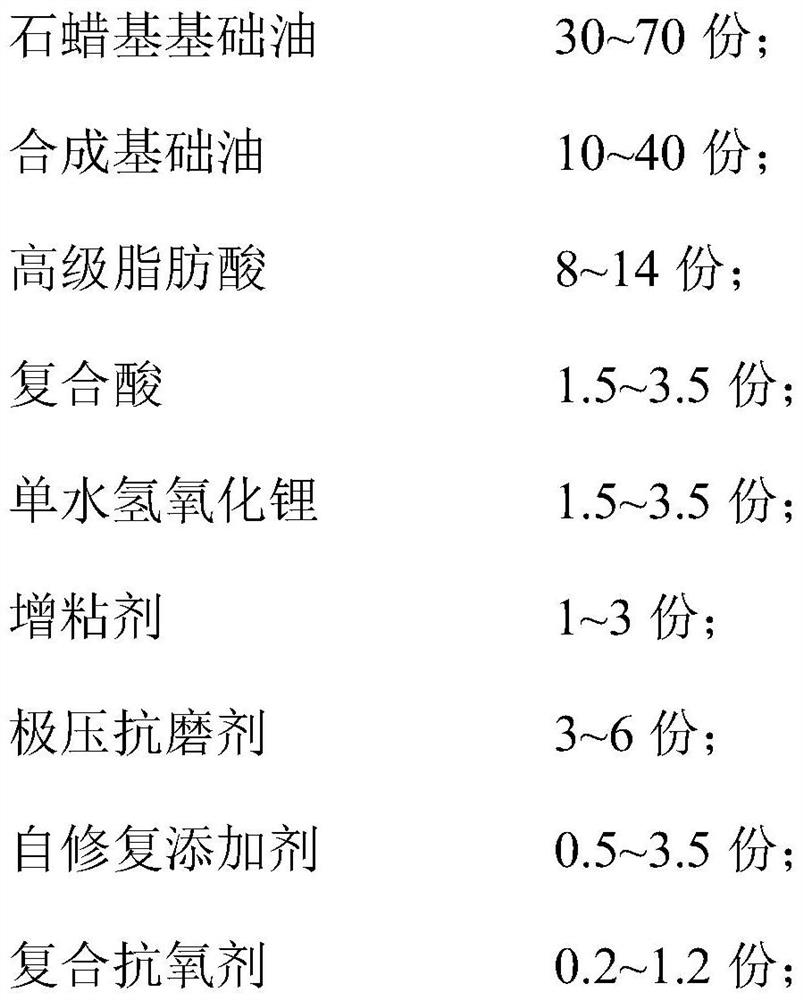

[0040] Among them, in parts by weight, the addition amount of each raw material is: 30-70 parts of paraffin base oil, 10-40 parts of synthetic base oil, 8-14 parts of higher fatty acid, 1.5-3.5 p...

Embodiment 1

[0050] The petrochemical industry standard first-class extreme pressure lithium complex grease prepared in this example is counted in parts by weight, and the prepared raw materials include: 51.22 parts of paraffin-based base oil, 25 parts of synthetic base oil, 10 parts of higher fatty acids, 2.4 parts of complex Acid, 2.38 parts lithium hydroxide monohydrate, 2 parts tackifier, 4 parts extreme pressure antiwear agent, 2 parts self-healing additive, 0.6 part composite antioxidant, 0.4 part corrosion inhibitor.

[0051] Among them, the paraffin base oil is 1-400SN. Synthetic base oil is made of synthetic hydrocarbon base oil. 12-hydroxystearic acid is selected as the higher fatty acid. 2.4 parts complex acid is a mixture of 1.2 parts sebacic acid, 0.6 parts salicylic acid and 0.6 parts boric acid. The tackifier is polyisobutylene. The 4 parts extreme pressure antiwear agent is a mixture of 2 parts borate and 2 parts molybdenum dialkyldithiocarbamate. 0.6 part of composite ...

Embodiment 2

[0056] The petrochemical industry standard first-class extreme pressure lithium complex grease prepared in this example is counted in parts by weight, and the prepared raw materials include: 51.22 parts of paraffin-based base oil, 25 parts of synthetic base oil, 10 parts of higher fatty acids, 2.4 parts of complex Acid, 2.38 parts lithium hydroxide monohydrate, 2 parts tackifier, 4 parts extreme pressure antiwear agent, 2 parts self-healing additive, 0.6 part composite antioxidant, 0.4 part corrosion inhibitor.

[0057] Among them, the paraffin base oil is 1-500SN. Synthetic base oil is made of synthetic ester base oil. 12-hydroxystearic acid is selected as the higher fatty acid. 2.4 parts complex acid is a mixture of 1.2 parts sebacic acid, 0.6 parts salicylic acid and 0.6 parts boric acid. The tackifier is polymethacrylate. The 4 parts extreme pressure antiwear agent is a mixture of 2 parts borate and 2 parts zinc dialkyldithiophosphate. 0.6 part of composite antioxidant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com