Forklift truck transverse beam section rolling technique

A process method and beam technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as low strength, and achieve the effects of reducing material loss, saving materials, and reducing social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] At present, the process adopted in manufacturing the forklift beam is to directly roll the billet into the forklift beam profile steel with the beam end face size, and then cut the material according to the length of the finished component. Forklift beam steel has a variety of 1.5 tons to 5 tons of forklift steel, which is used as a load-bearing component and is the main material for manufacturing the beam of a forklift load-bearing component.

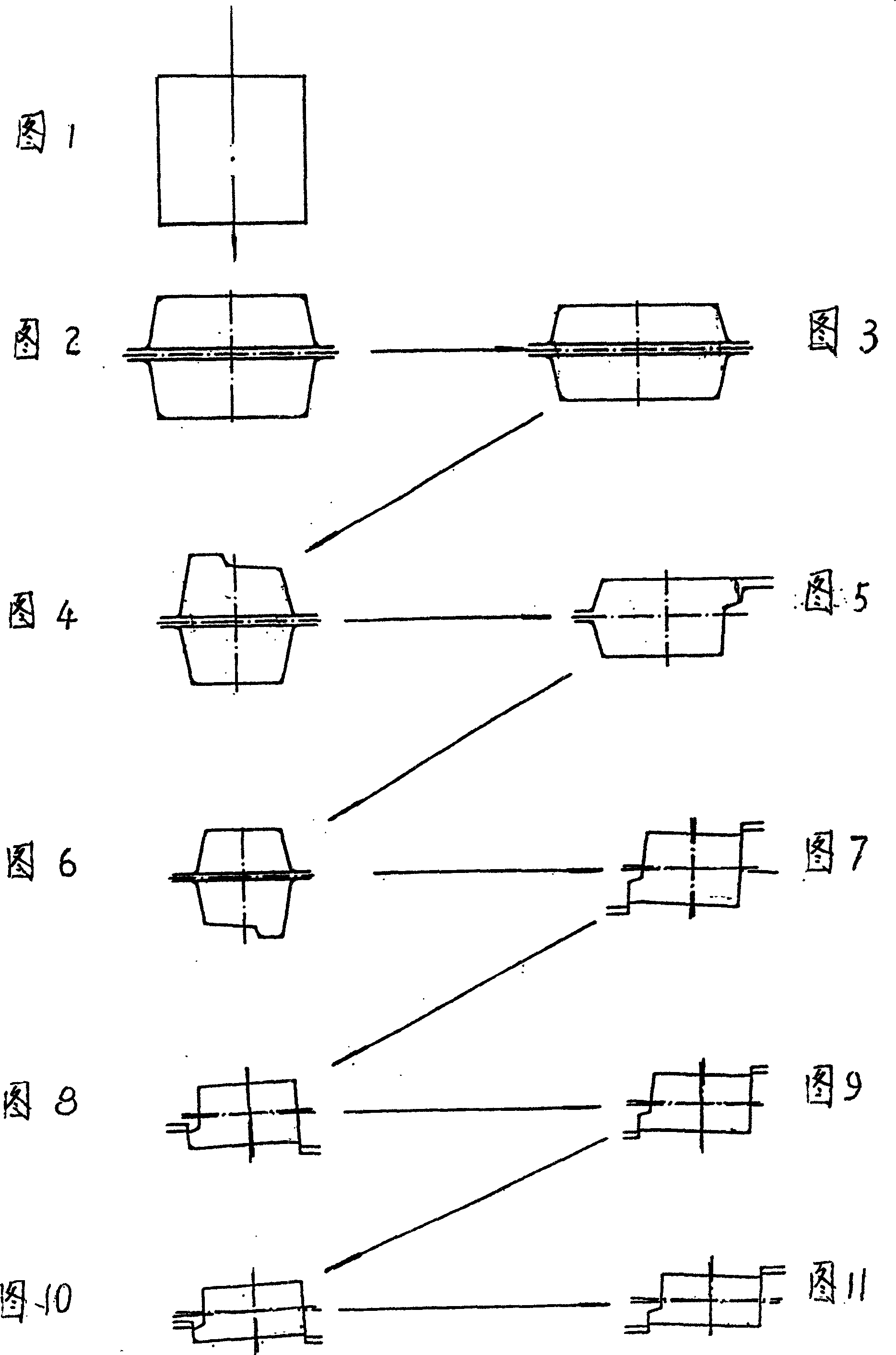

[0024] The rolling process of forklift beam section steel is as follows;

[0025] The -- in Figure 1-11 indicates the rolling process; after the reciprocating rolling pass pattern 3-6, after 4 passes exiting the pass pattern, each turn right at an angle of 90°, and then enter the next pass pass rolling.

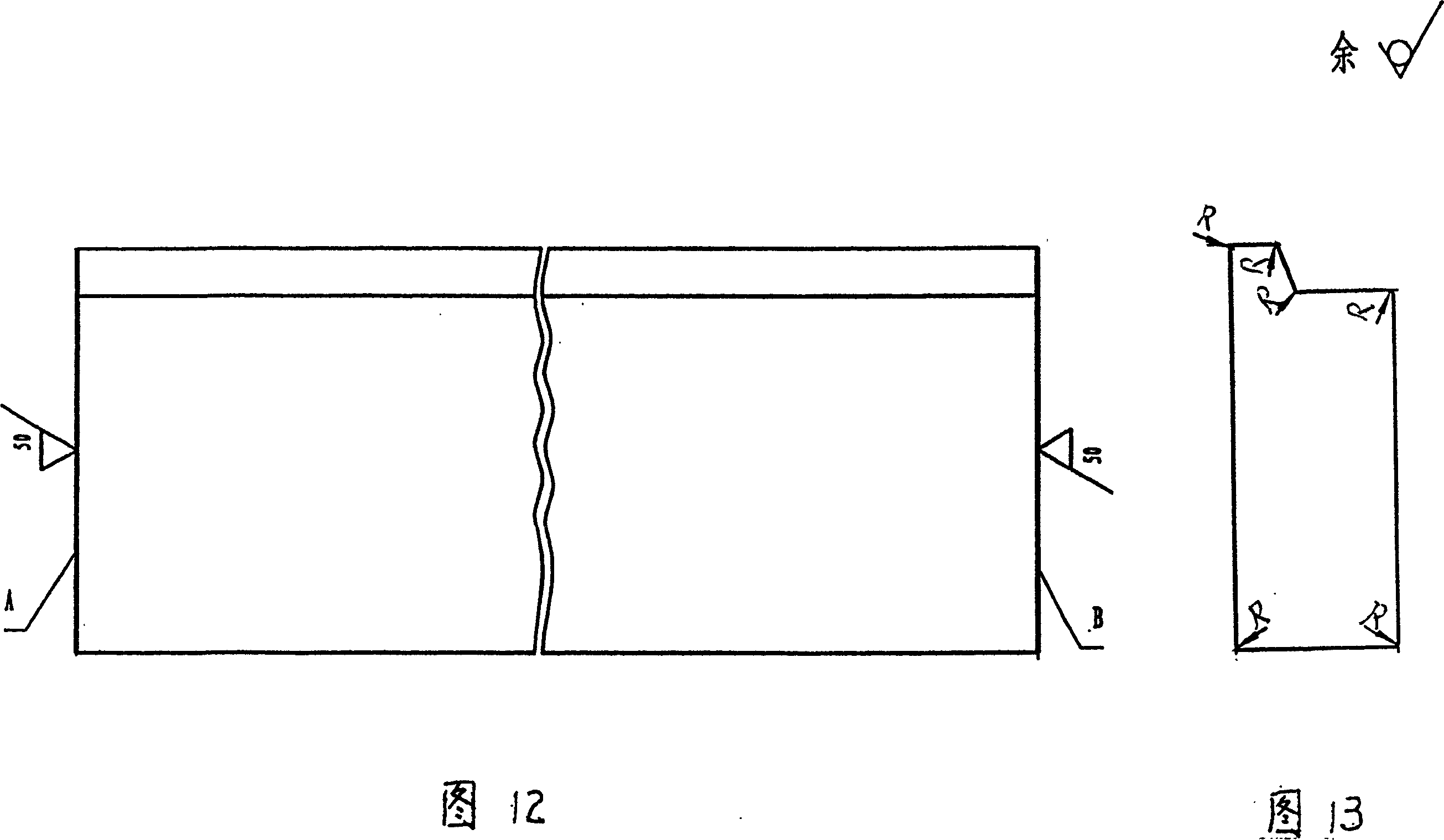

[0026] 1), the material meets the user's requirements of chemical composition 150mm 2 The square steel billet is cut into a certain length size according to the process requirements, such as the size of 2.5-2.8m.

[0027] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com