Two-in-one method for processing narrow series thin-wall bearing ferrule

A technology of thin-walled bearings and processing methods, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as easy warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

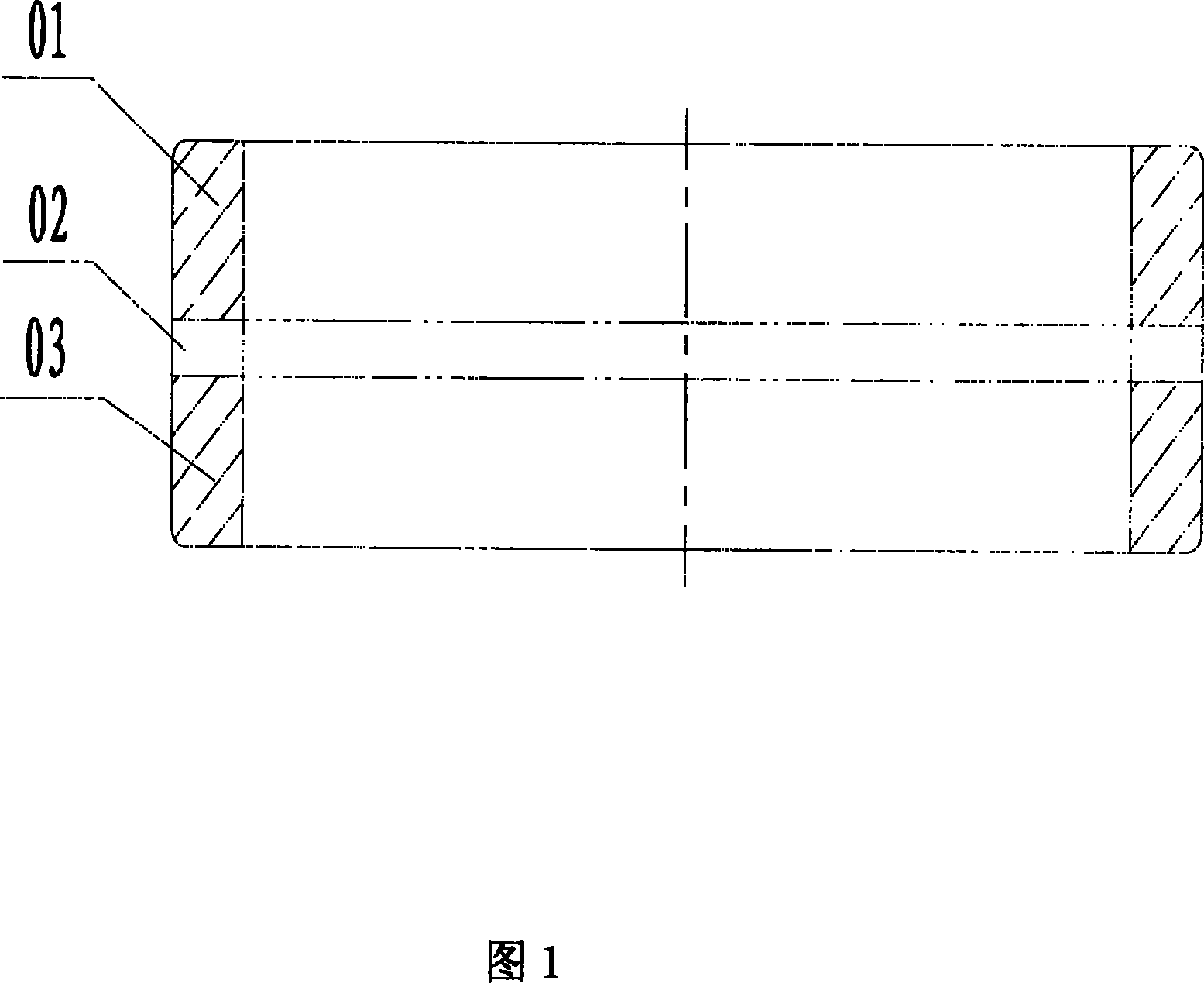

[0011] As shown in Fig. 1, the two-in-one processing method of the narrow series of thin-walled bearing rings means that two narrow series of thin-walled bearing ring blanks are processed and formed, and then cut and separated. The processing process is as follows: forging the preliminary formed blank raw material, first clamping and positioning at one end, turning the end face, inner diameter surface and the entire outer diameter surface of the other end and chamfering; then transposition clamping and positioning, turning the end face, inner diameter surface, inner diameter The chamfering treatment is carried out on the groove; after heat treatment, each forming surface is first finished; finally, it is cut along the cut (02), and the cut section is finished, and the aging treatment is carried out. Two bearing rings (01, 03) are thus produced simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com