Hermetic refrigerant compressor

A refrigerant and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as reduction, and achieve the effect of reducing flow loss and small pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

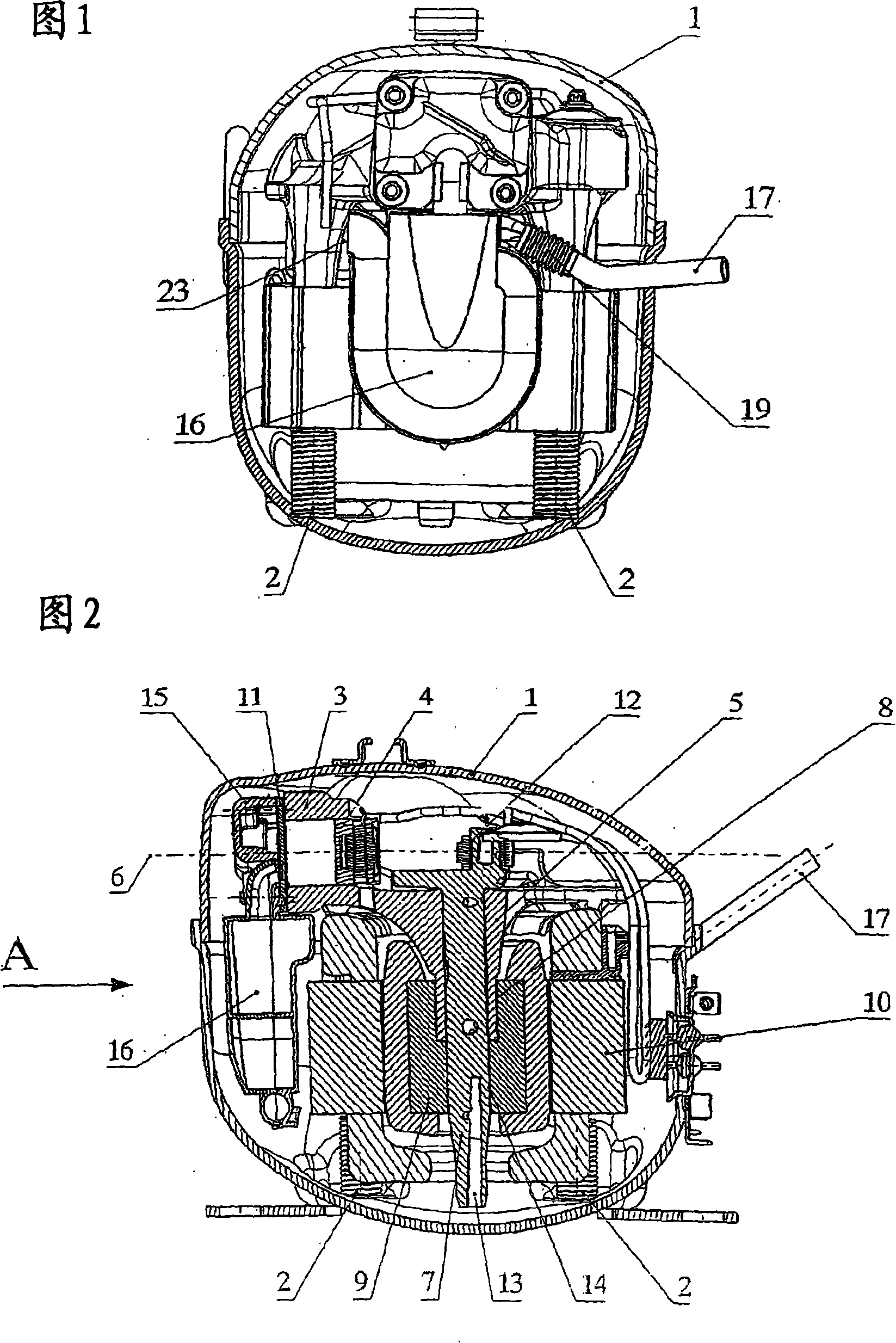

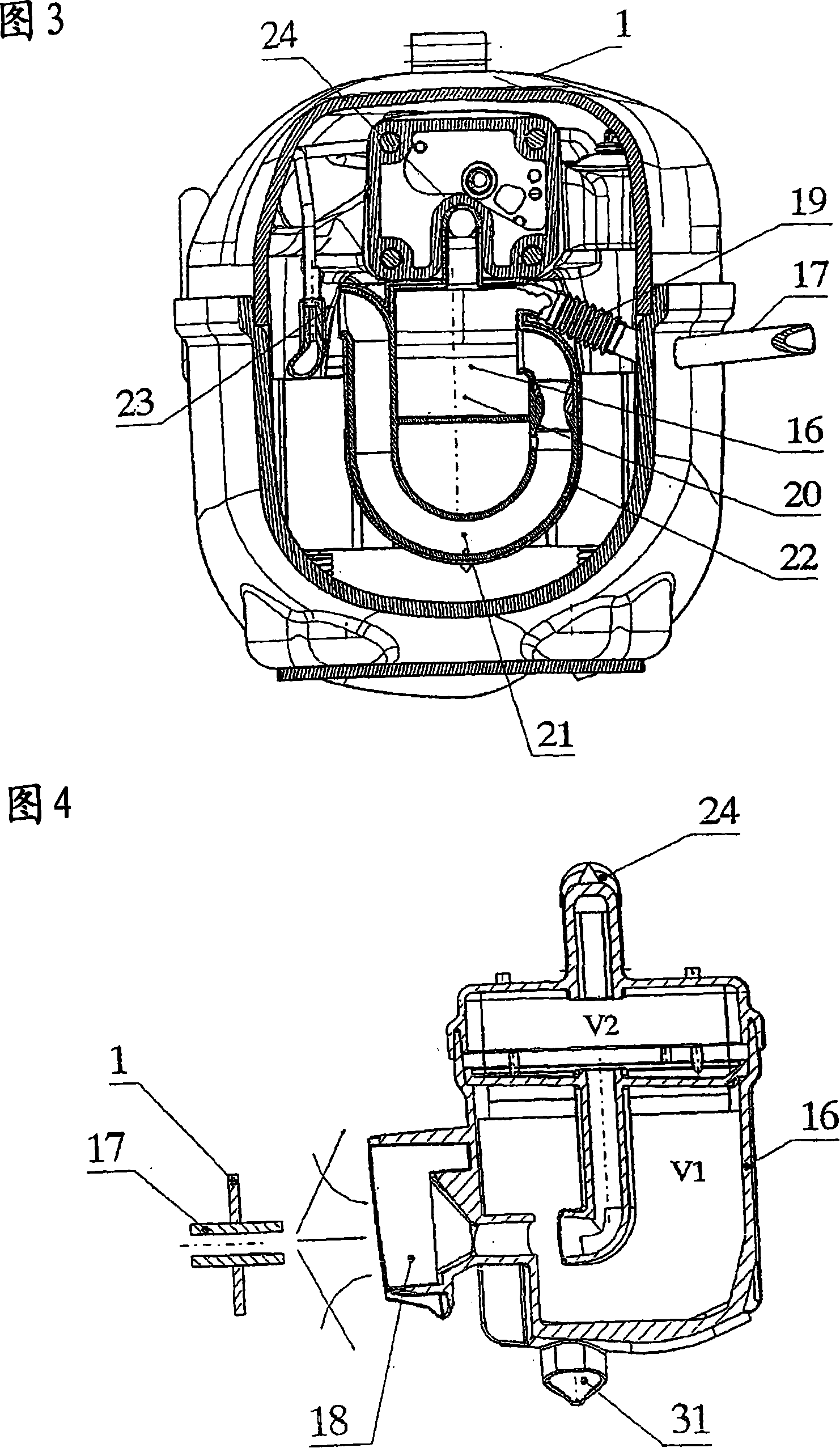

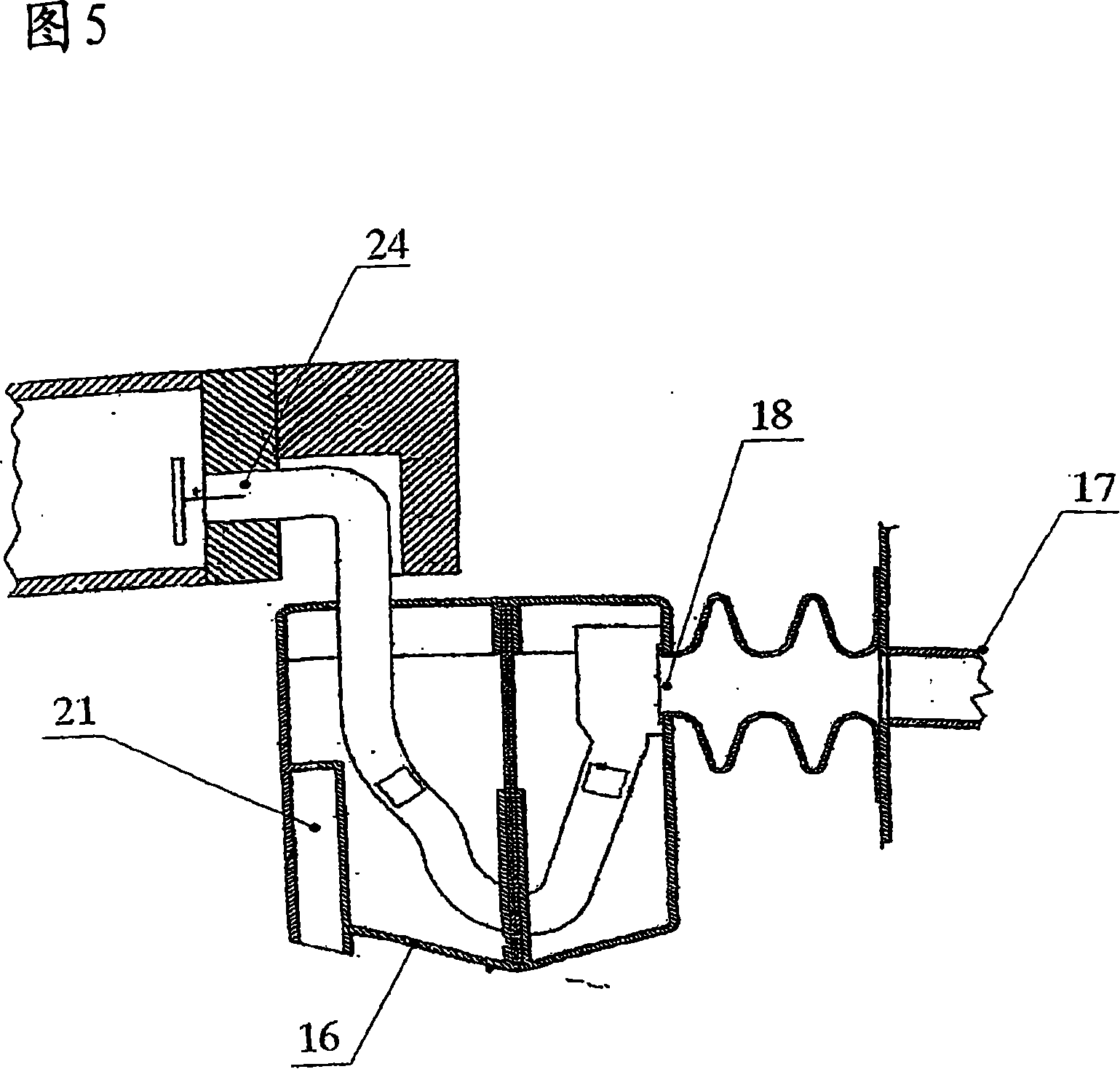

[0048] 1, 2 and 3 respectively show a sectional view of a hermetically sealed refrigerant compressor, wherein Figs. 1 and 3 respectively show views along the direction of arrow A in Fig. 2 . A piston cylinder motor unit is elastically supported by springs 2 inside the hermetically closed compressor housing 1 .

[0049] The piston working cylinder motor unit is mainly composed of a cylindrical housing 3 and a reciprocating piston 4 inside it, and a crank bearing 5, which is arranged perpendicular to the axis 6 of the working cylinder. The crankshaft bearing 5 supports a crankshaft 7 and projects into a central bore 8 of a rotor 9 of an electric motor 10 . At the upper end of the crankshaft 7 there is a connecting rod bearing 12 through which the connecting rod is driven and the piston 4 is further driven. The crankshaft 7 has a lubricating oil hole 13 and is fastened in a region 14 on the rotor 9 . The suction muffler 16 is arranged on the working cylinder head 15, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com