Production of composite corundum carbon brick for ladle

A corundum carbon brick and production method technology, applied in the field of refractory material production, can solve the problems of low product grade, high carbon content, unfavorable heat preservation of molten steel, etc., and achieve the effect of improving service life and high continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

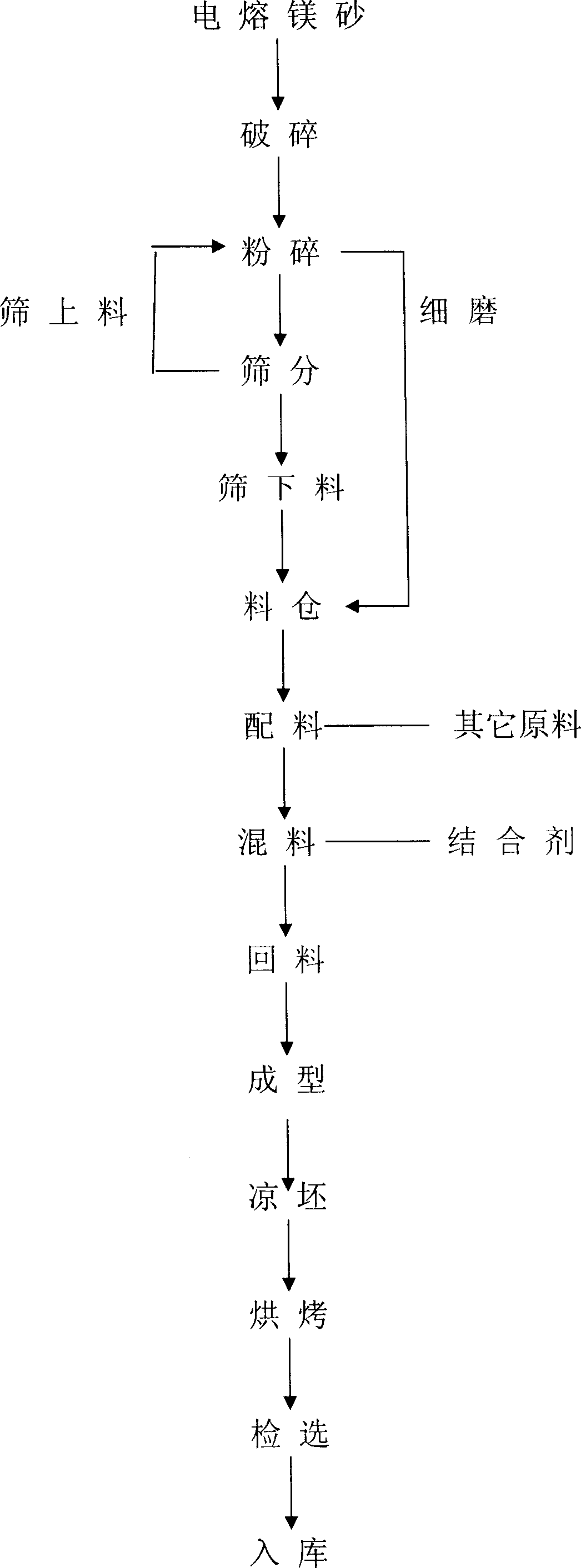

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with embodiment.

[0018] This process selects sub-white corundum, fused magnesia, fused spinel, etc. as the main raw materials. Specifically, its raw material ratio is as follows (mass percentage): 35-40% of sub-white corundum, 25-40% of fused magnesia 35%, fused aluminum magnesium spinel 10-15%, graphite 6-7%, metal aluminum 1-2%, metal silicon 1-3%, 95 silicon carbide 3-5%, alumina 3-5%, Resin 3.5-3.8%. Among them, metal aluminum, metal silicon and silicon carbide are antioxidants, aluminum oxide is a sintering agent, and resin is a binder.

[0019] Requirements for the properties of the above-mentioned raw materials: sub-white corundum is granules, composed of two specifications of 1-3mm and 3-5mm in particle size, accounting for 20-25% and 10-15% of the total mass of raw materials respectively; the fused magnesia Granules are composed of three sizes of 0-1mm, 1-3mm and 3-5mm, respectively accountin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com