Inert gas protection and on-line detecting ultra-fine comminuting system

An inert gas, ultra-fine pulverization technology, used in grain processing and other directions, can solve the problems of high personnel skill requirements, large fluctuation range of product particle size, product scrapping, etc., to ensure product quality and reduce the effect of particle size fluctuation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

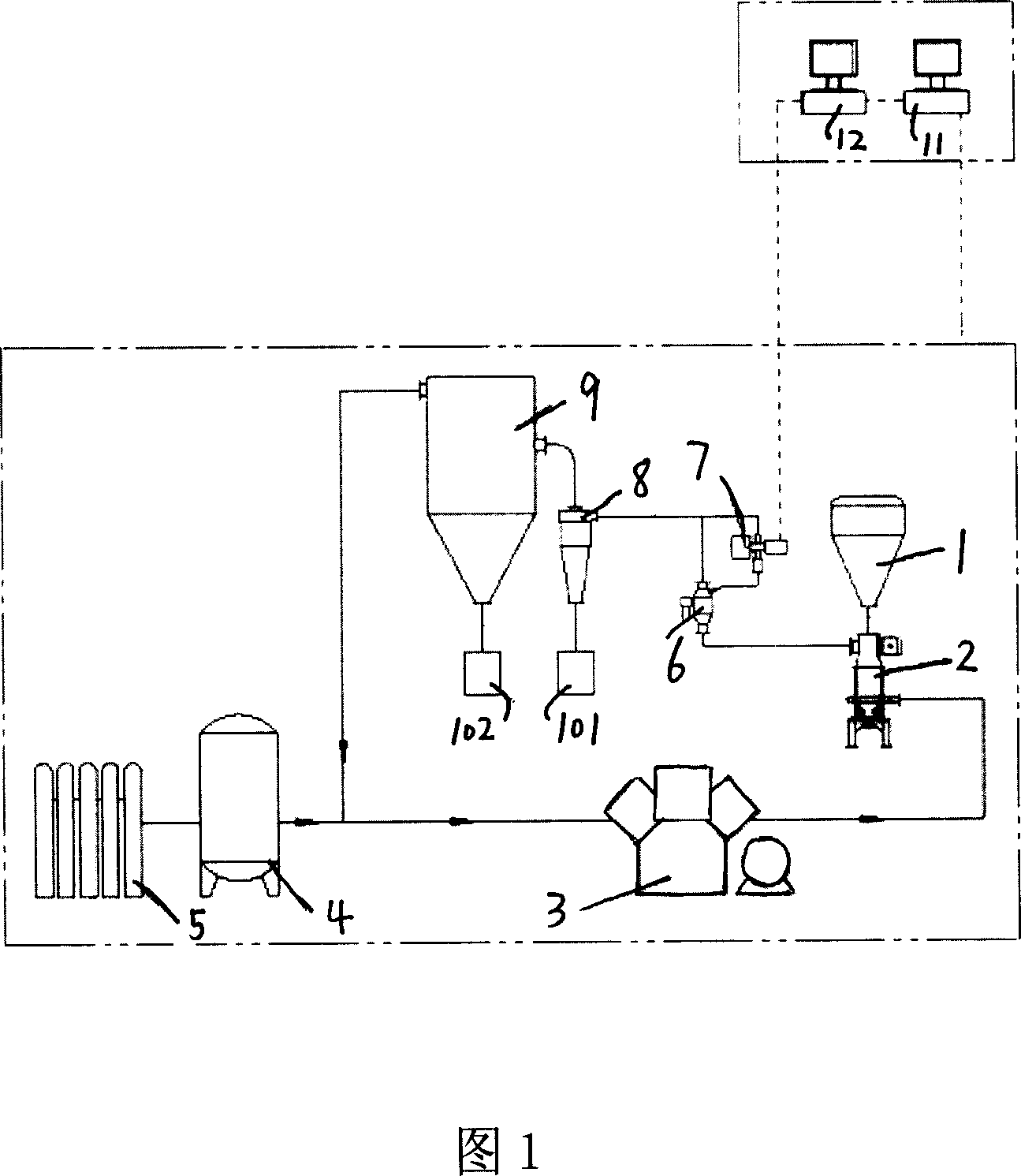

[0015] Embodiment: an inert gas protection and on-line detection ultra-fine pulverization system, mainly including a silo 1, a pulverization host 2, a compressor 3, a gas storage tank 4, an inert gas source 5, an online sampler 6, a laser detector 7, Cyclone separator 8, catcher 9, the material outlet of silo 1 is connected with the material inlet of crushing host 2, the material outlet of crushing host 2 is connected with the upper inlet of cyclone separator 8, and the upper outlet of cyclone separator 8 is connected with the upper end of catcher 9 The inlets are connected, the material outlets of the cyclone separator 8 and the catcher 9 are connected with the first and second finished product barrels 101 and 102 respectively, the gas outlet on the upper part of the catcher 9 is connected with the suction port of the compressor 3, and the gas outlet of the compressor 3 The outlet communicates with the gas inlet of the crushing host 2, the gas outlet of the inert gas source 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com