Novel rhombohedral iron ore beneficiation technics

A process and grinding technology, applied in flotation, solid separation, wet separation, etc., can solve the problems of iron component loss, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

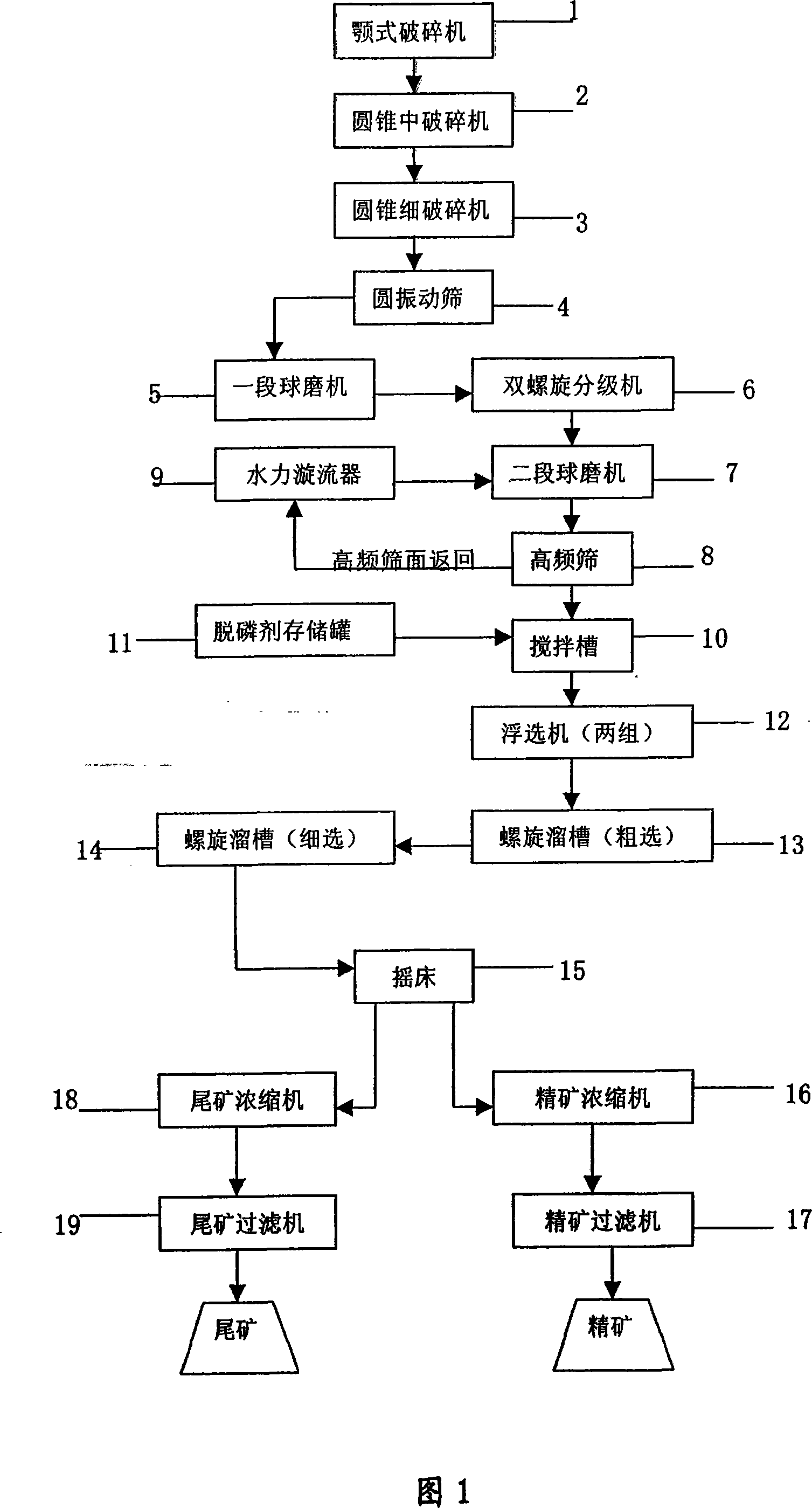

Method used

Image

Examples

Embodiment 1

[0057] 300 tons of hematite main components: Fe: 45%, P: 1.8%, SiO 2 : 18%

[0058] After applying natural silicon and dephosphorizing agent and flotation twice, Fe: 52%, P: 0.36%, SiO 2 : 4.5%

[0059] After the coarse selection spiral chute and the fine selection spiral chute are sorted, Fe: 60%, P: 0.24%, SiO 2 : 4%.

[0060] Sweep through a shaker, Fe: 63% P: 0.1%, SiO 2 : 3.5%.

[0061] Finally, 150t of concentrate was obtained.

[0062] The first grade concentrate is 95t, accounting for 63.33% of the 150t concentrate, Fe: 63%, P: 0.1%, SiO 2 : 3.5%, (exceeding national standards)

[0063] 40t secondary concentrate powder, accounting for 26.67% of 150t concentrate, Fe: 60%, P: 0.25%, SiO 2 : 3.8%, (national standard)

[0064] Mixed use of 15t medium ore, 10% of 150t concentrate, Fe: 56%, P: 0.3%, SiO 2 : 4.5% mixed use of sintered ore.

[0065] The tailings are 129t, accounting for 43% of the 300t ore.

Embodiment 2

[0067] 1000t hematite main components: Fe: 45%, P: 2.0%, SiO 2 : 20%

[0068] After applying natural silicon and dephosphorizing agent and after two flotation, Fe: 52%, P: 0.4%, SiO 2 : 5%

[0069] After the coarse selection spiral chute and the fine selection spiral chute are sorted, Fe: 60%, P: 0.26%, SiO 2 : 4.2%.

[0070] Sweep through a shaker, Fe: 63% P: 0.1%, SiO 2 : 3.5%.

[0071] Finally, 500t of concentrate is obtained.

[0072] The first grade concentrate is 316.7t, accounting for 63.33% of the 500t concentrate, Fe: 63%, P: 0.1%, SiO 2: 3.5%, (exceeding national standards)

[0073] The secondary concentrate powder is 133.33t, accounting for 26.67% of the 500t concentrate, Fe: 60%, P: 0.28%, SiO 2 : 4%, (national standard)

[0074] Mixed use of medium ore 50t, accounting for 10% of 500t concentrate, Fe: 56%, P: 0.3%, SiO 2 : 4.5% mixed use of sintered ore.

[0075] The tailings are 430t, accounting for 43% of the 1000t ore.

Embodiment 3

[0077] 3000t hematite main components: Fe: 45%, P: 2.2%, SiO 2 :twenty two%

[0078] After applying natural silicon and dephosphorizing agent and after two flotation, Fe: 53%, P: 0.44%, SiO 2 : 5.5%

[0079] After the coarse selection spiral chute and the fine selection spiral chute are sorted, Fe: 60%, P: 0.28%, SiO 2 : 4.2%.

[0080] Sweep through a shaker, Fe: 63% P: 0.1%, SiO 2 : 3.5%.

[0081] Finally, 1500t of concentrate was obtained.

[0082] Among them, the first grade concentrate is 950t, accounting for 63.33% of the 1500t concentrate, Fe: 63%, P: 0.1%, SiO 2 : 3.5%, (exceeding national standards)

[0083] 400t secondary concentrate powder, accounting for 26.67% of 1500t concentrate, Fe: 60%, P: 0.26%, SiO 2 : 3.9%, (national standard)

[0084] Mixed use of 150t medium ore, accounting for 10% of 1500t concentrate, Fe: 56%, P: 0.3%, SiO 2 : 4.6% mixed use of sintered ore.

[0085] The tailings are 1290t, accounting for 43% of the 3000t ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com