Solid wood composite coining door panel and production technology thereof

A solid wood composite and molding technology, which is applied to wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of high cost, inability to form batches, easy to open glue, etc. texture real effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

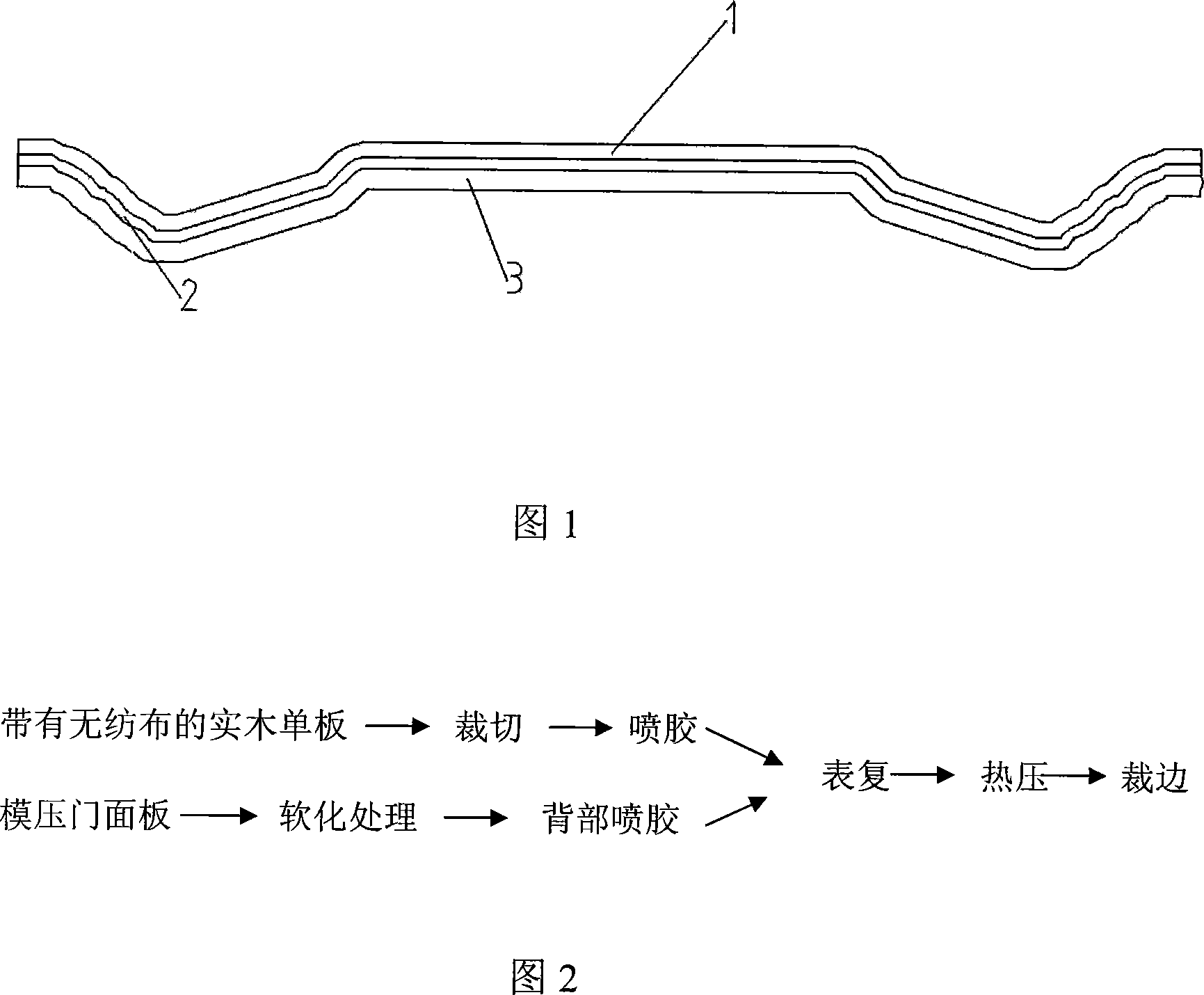

[0023] 1. Take the high-density molded door panel 3 with two panels, the surface is smooth, and the size is 3.2*2150*860mm. The surface is evenly sprayed with ammonia water with a concentration of 5%, and placed at room temperature for 8 to 24 hours to achieve the purpose of rewetting and softening the molded door panel.

[0024] 2. Take a natural solid wood veneer 1 with a thickness of 0.2 mm and a non-woven fabric 2 on the back (the wood species is oak wood). The upper and lower studs and other parts are cut into seven solid wood veneer components in sequence. The principle is that the door studs and stud head veneer components are cut according to the actual size of the door panel or according to the shape and size of the door studs and studs. The solid wood veneer components of the panel part should be appropriately enlarged and cut according to the actual shape and size of the door panel panel, so as to prepare for the stretching and filling of the groove part.

[0025] ...

Embodiment 2

[0029] 1. Take the high-density molded door panel 3 without any shape, the surface is smooth, and the size is 3.2*2150*9200mm. The surface is evenly sprayed with ammonia water with a concentration of 5%, and placed at room temperature for 8 to 24 hours to achieve the purpose of rewetting and softening the molded door panel.

[0030] 2. Take several technical wood veneers 1 (the wood type is teak) with a thickness of 0.2 mm and a thickness of 0.2 mm on the back, and cut them to a certain length according to the length of the molded door panel.

[0031] 3. Evenly spray the modified urea-aldehyde resin on the surface of the softened molded door panel 3 and the back of the cut technical wood veneer 1 component (the side with the non-woven fabric), and dry it in a drying oven or dry it naturally at room temperature Dry.

[0032] 4. Put glue-dried high-tech wood veneer 1 specifications in sequence on the molded door panel after glue-spraying and drying.

[0033] 5. Put the molded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com