Plant and method for liquefying natural gas

A technology for liquefied natural gas and natural gas, applied in liquefaction, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as increased pressure, reduced liquefaction efficiency, and complex equal distribution, and achieves the effect of simple method and increased overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

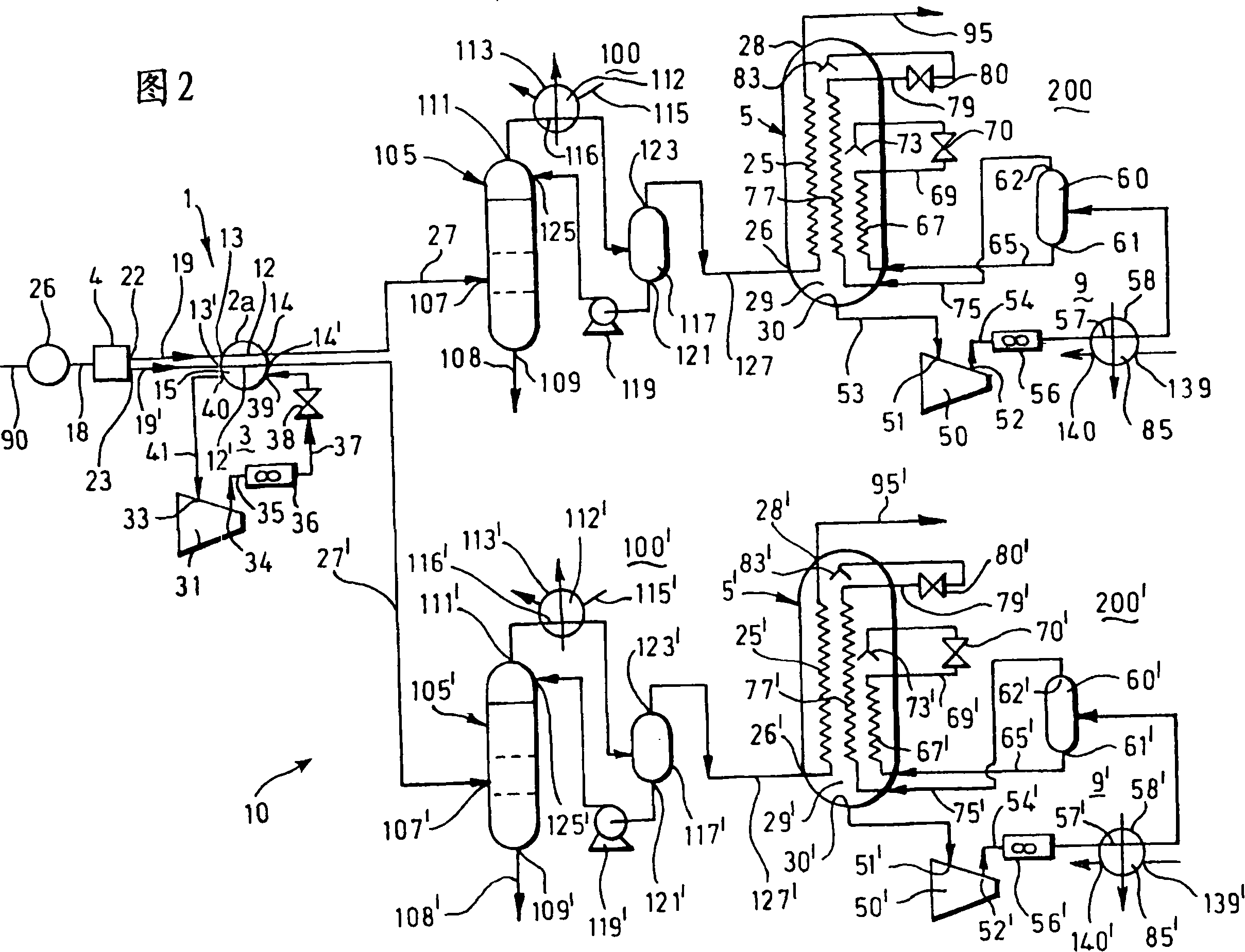

[0035] For descriptive purposes, a single reference number will be assigned to the pipeline and the natural gas stream conveyed in the pipeline. Like numbers refer to like parts.

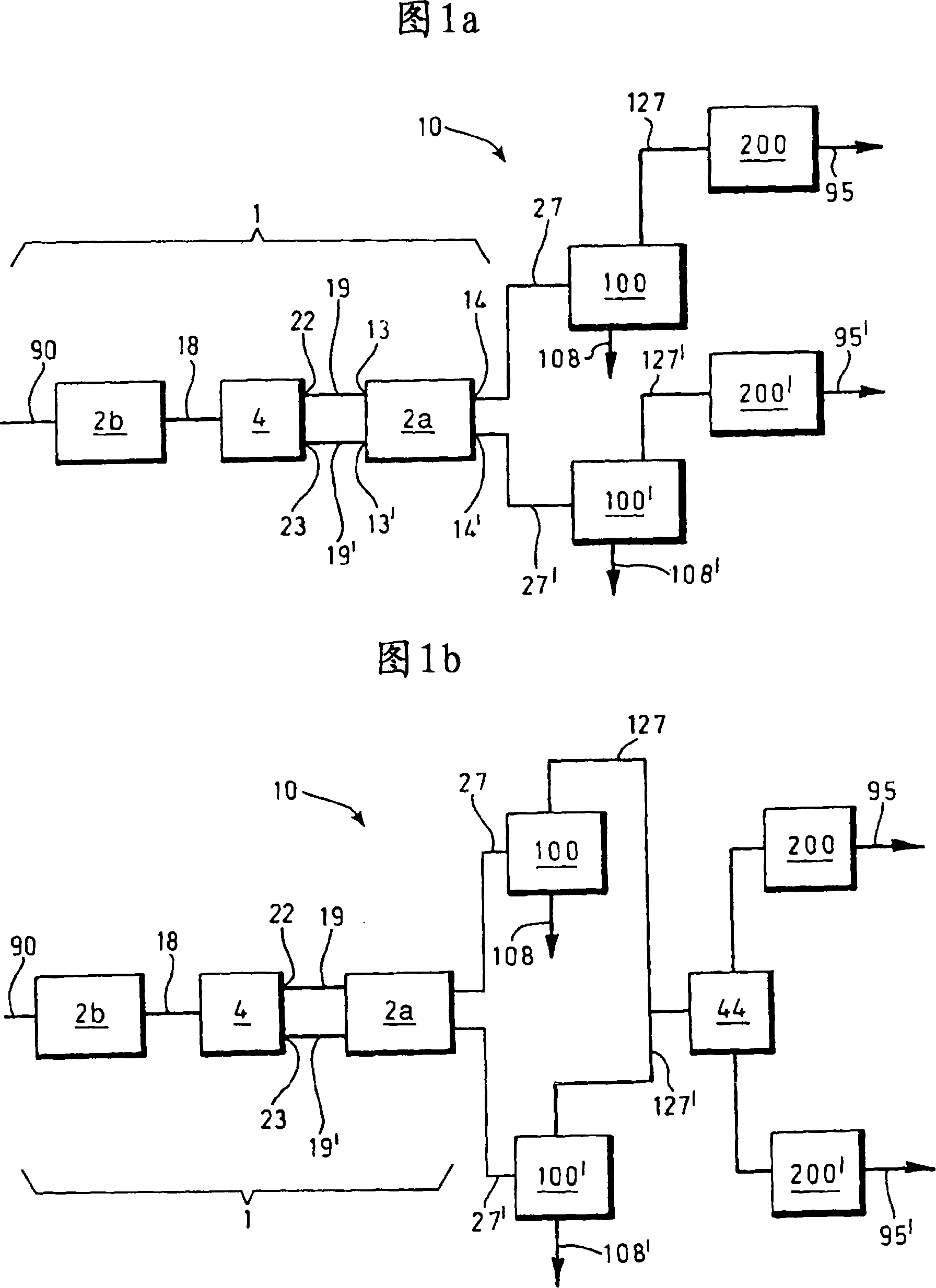

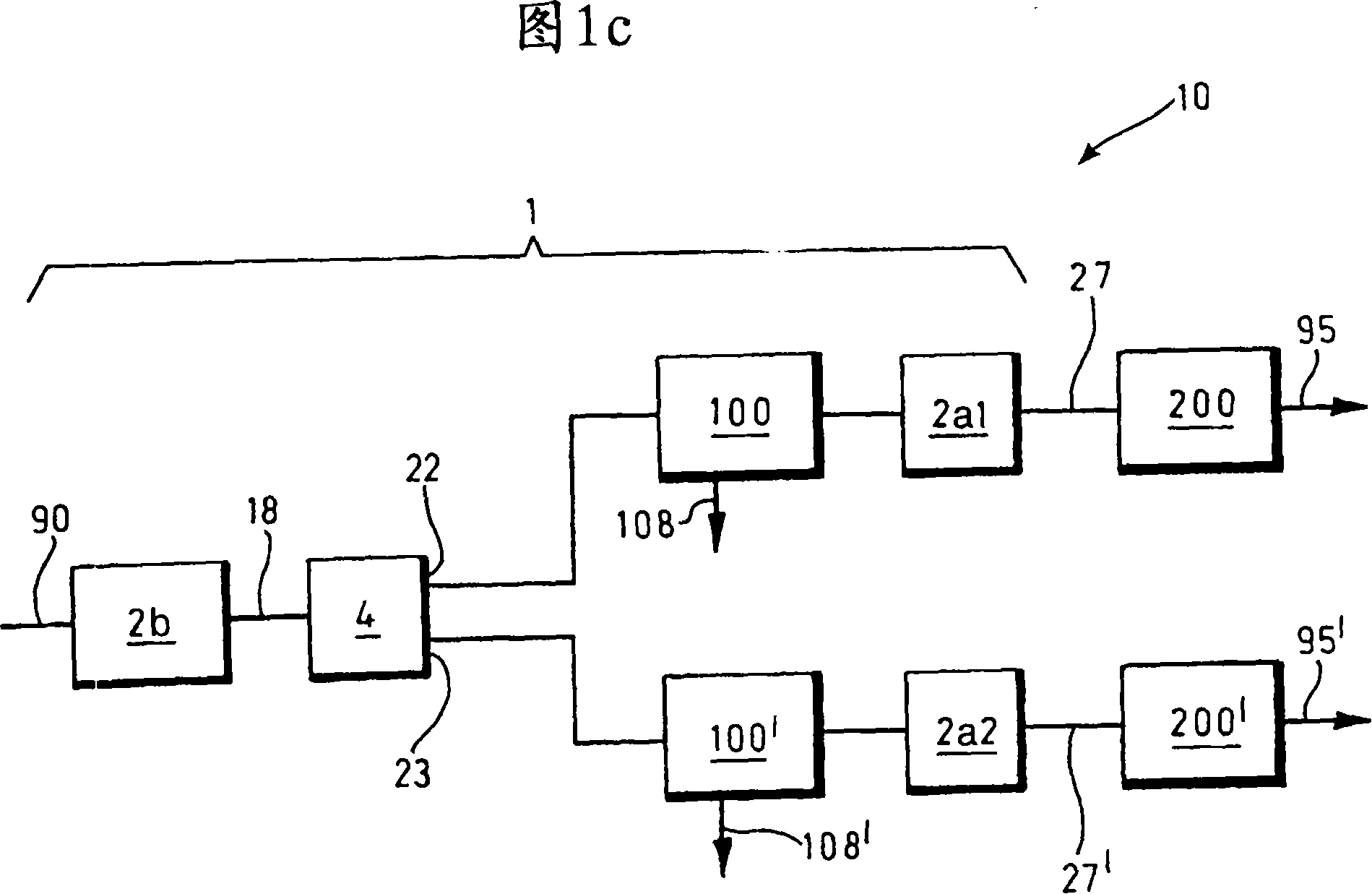

[0036] See Figures 1a-1c. The plant 10 for liquefaction of natural gas according to the invention comprises: a natural gas precooling heat exchanger chain 1, a distributor 4, two main cryogenic systems 200 and 200', and optionally two natural gas liquid extraction units 100 and 100'. The precooling heat exchanger chain 1 has an inlet line 90 for natural gas and outlet lines 27, 27' for precooled natural gas. In the embodiment shown in Figures 1a-1c, the pre-cooling heat exchanger chain 1 comprises two heat exchangers 2a, 2b, wherein the heat exchanger 2a is the final heat exchanger. Those skilled in the art will appreciate that the chain 1 may comprise more than two heat exchangers. If desired (and preferred), the heat exchangers of chain 1 can be part of the same refrigerant circuit.

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com