Efficient wear-proof drum type cyclone dust collector

A cyclone dust collector and anti-wear technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problem of unreasonable airflow distribution in the pressure distribution chamber, inconvenient manufacturing and installation of spiral cylinders, and cyclone separation. The problem of uneven wear on the side wall of the chamber can improve the safety performance, improve the cyclone effect, and reduce the wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

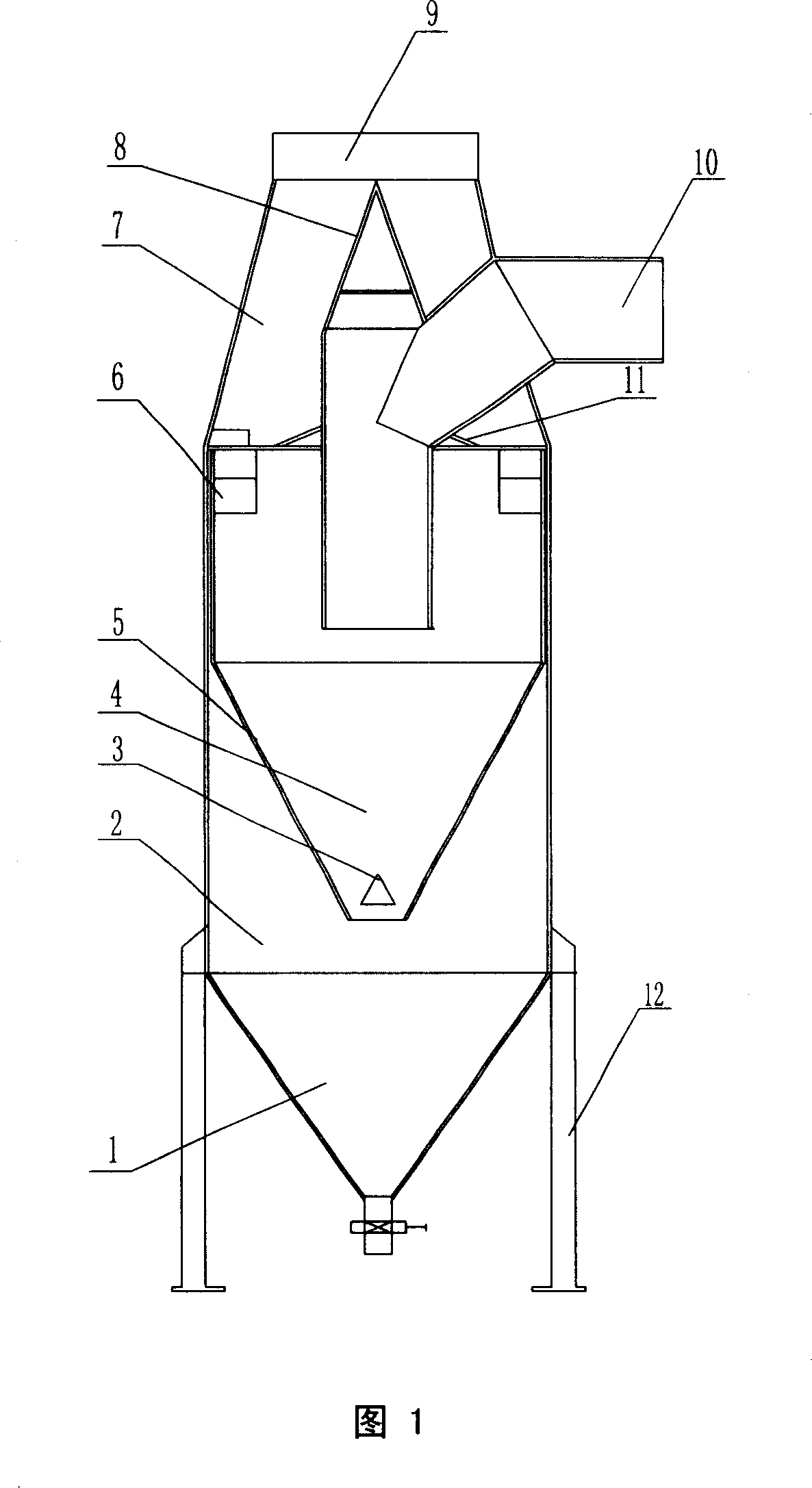

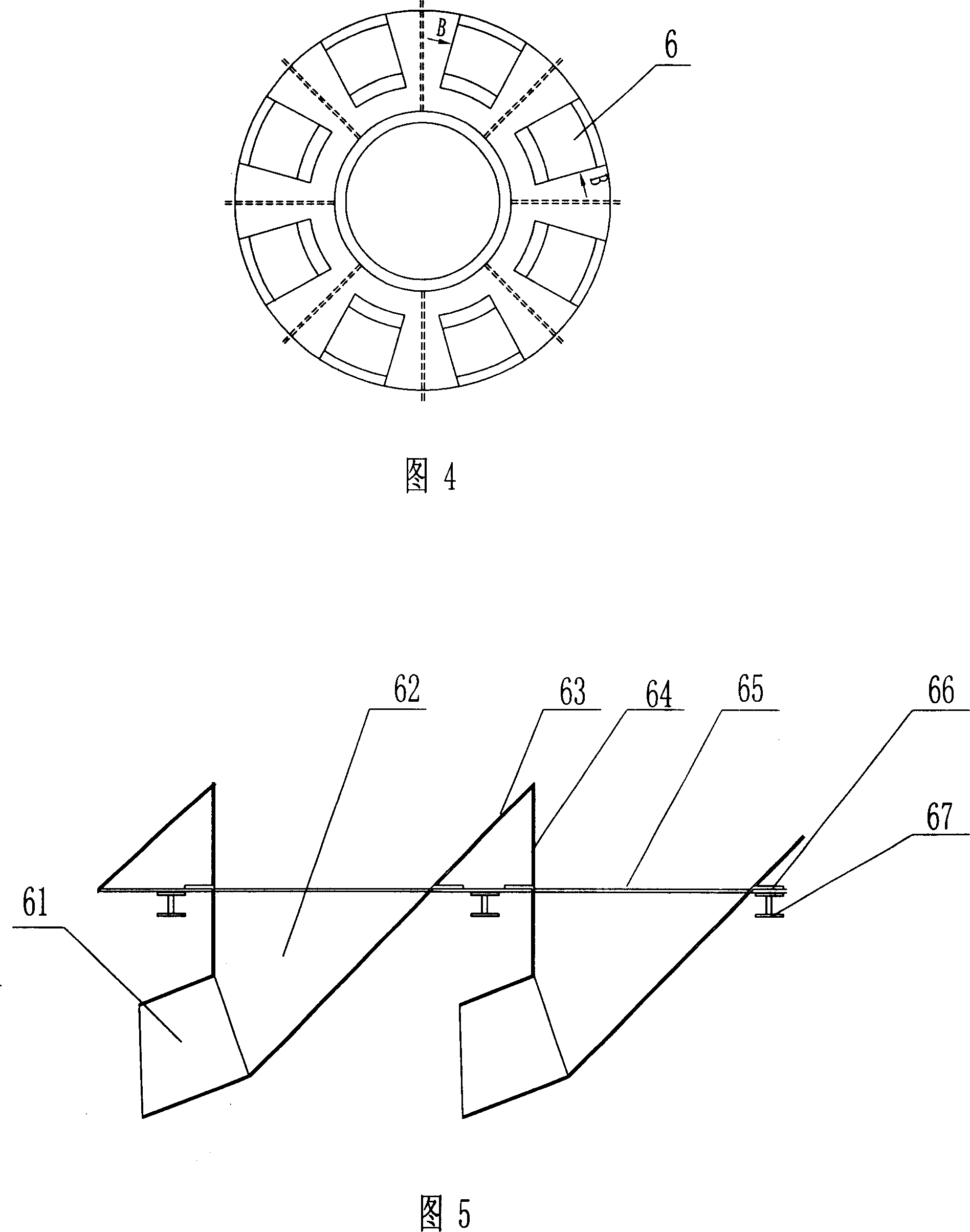

[0031] As shown in Fig. 1, the high-efficiency anti-grinding cylinder type cyclone dust collector of the present invention includes a waste gas inlet pipe 9, an exhaust pipe 10, an ash collecting bucket 1, a cyclone separation chamber, an airflow distribution chamber 7, and an airflow limiting dust suppressor 3 , characterized by:

[0032] 1) A central air distribution cone 8 is provided in the air distribution chamber 7, and the outer wall is an integral conical tube,

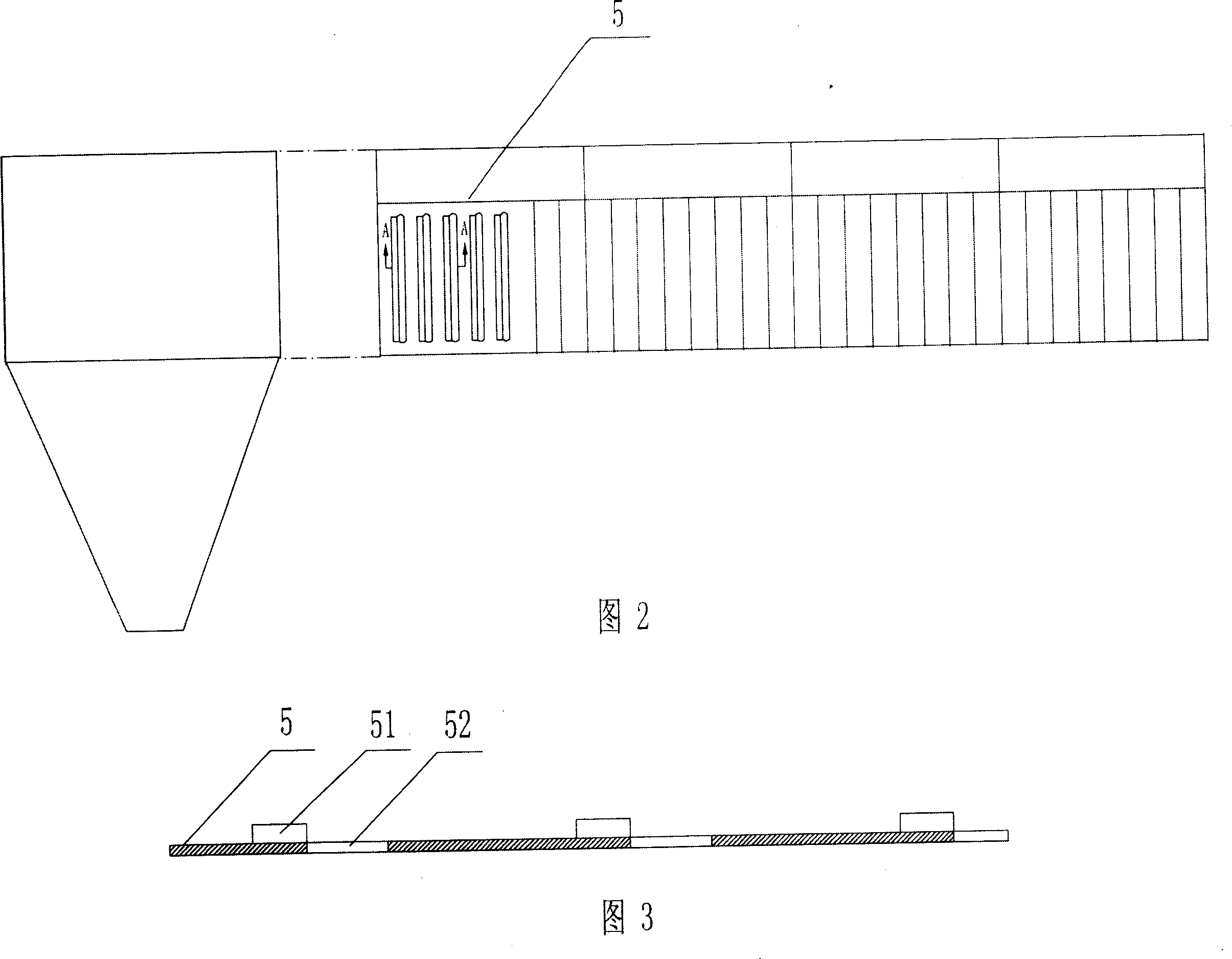

[0033] 2) The cyclone separation chamber is composed of an inner chamber 4 and an outer chamber 2, the air flow limiting dust suppressor 3 is arranged at the bottom of the inner chamber 4, and the inner chamber 4 is composed of an upper cylinder and a lower cone , the side walls 5 of the upper cylinder and the lower cone are porous side walls, and the lower part of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com