Method for manufacturing casing with textile fiber grain

A manufacturing method and technology for weaving fibers, which are used in fiber processing, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of high cost expenditure, the surface quality of finished shell products cannot be improved, etc. Thickness texture, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

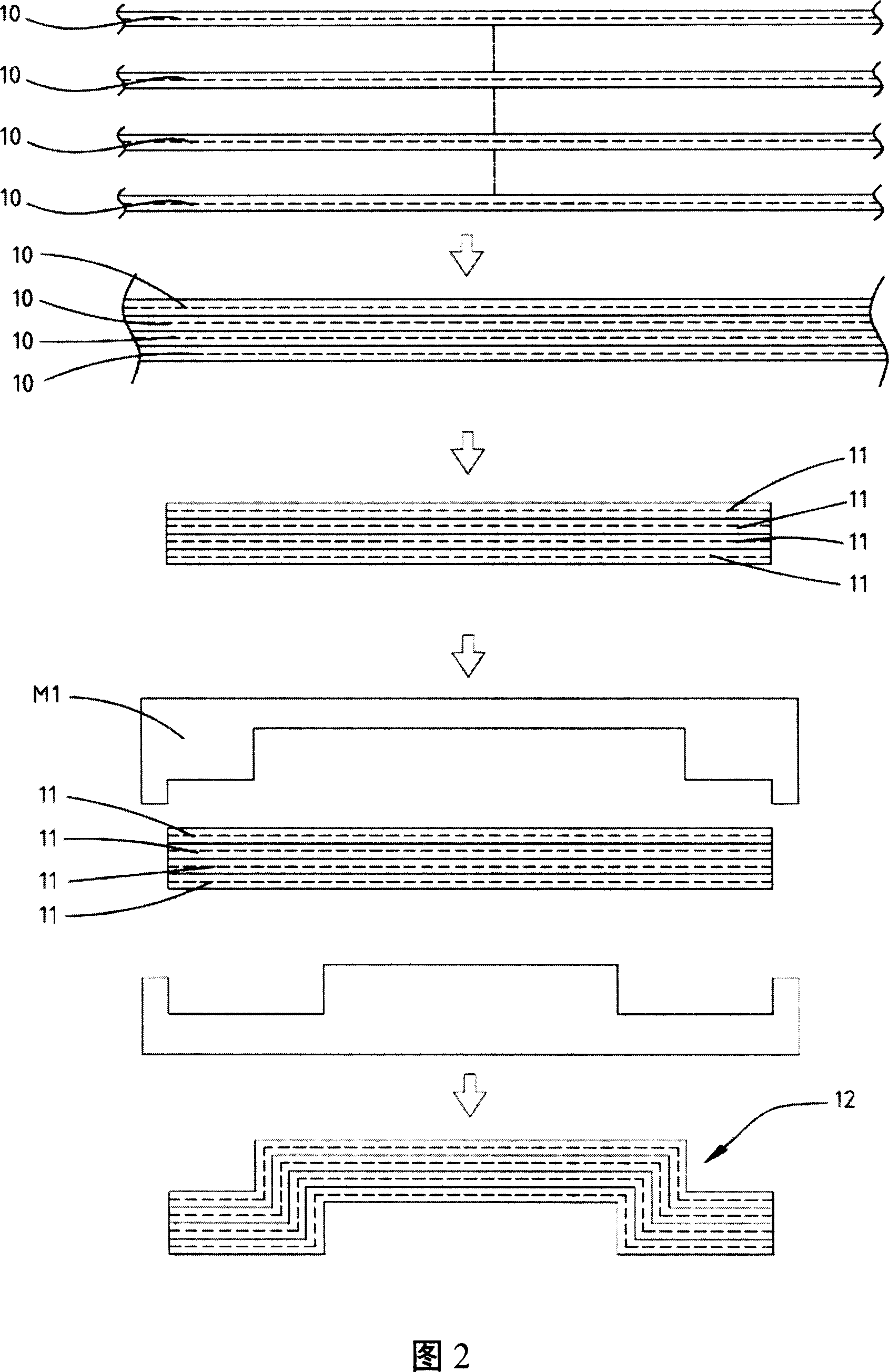

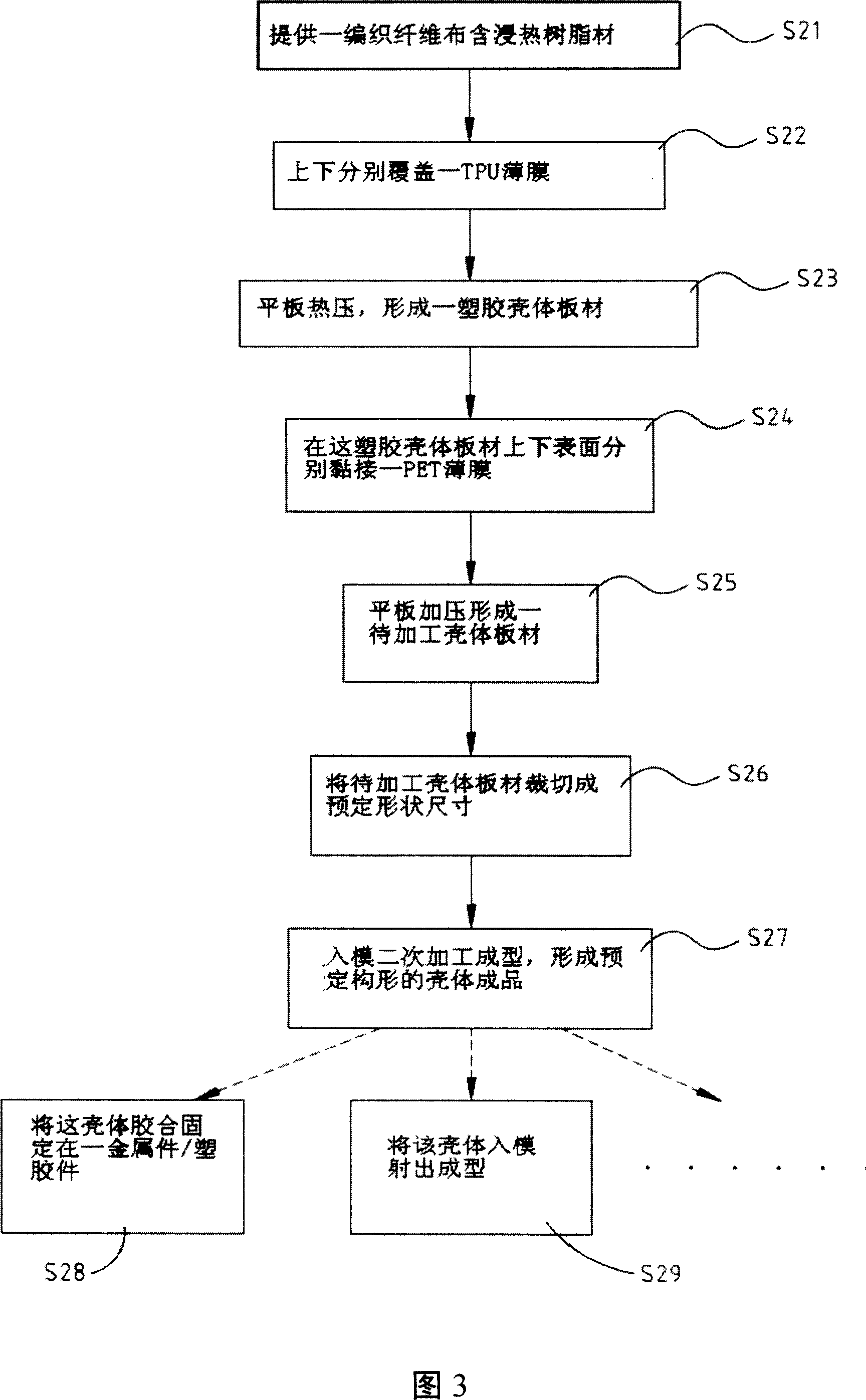

[0046] Please refer to FIG. 3 and FIG. 4 at the same time. FIG. 3 is a schematic flowchart of a manufacturing method according to an embodiment of the present invention, and FIG. 4 is a schematic view of a manufacturing method of a casing with a braided fiber pattern according to an embodiment of the present invention. The manufacturing method of the casing with the woven fiber texture of the present invention is mainly to cover the upper and lower surfaces of a woven fiber cloth impregnated with resin material 20 with the TPU film 30 respectively, and then carry out hot pressing on a flat plate. Afterwards, a PET film 50 is bonded to the upper and lower surfaces of the hot-pressed board, and then further molding is performed to form the finished product of the housing 62 .

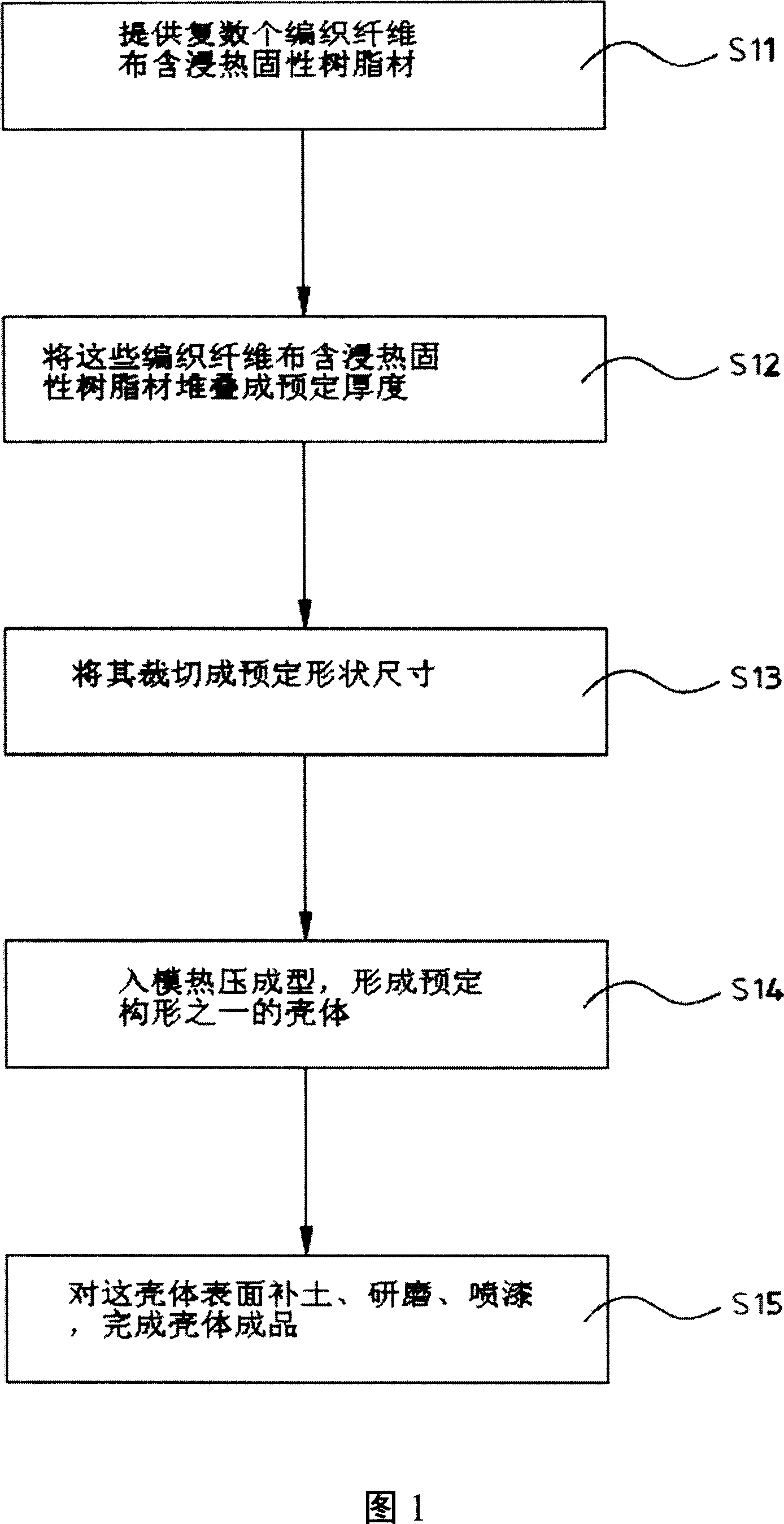

[0047] The manufacturing method of the embodiment of the present invention comprises the following steps: (1) providing a woven fiber cloth impregnated resin material S21; (2) covering the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com